ChevyParts

My Garage

My Account

Cart

OEM GMC Yukon XL 2500 Exhaust Manifold

Engine Exhaust Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Exhaust Manifolds found

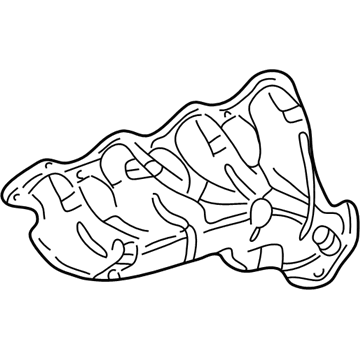

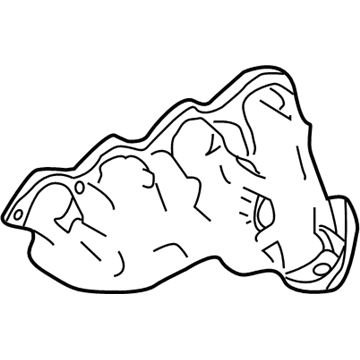

GMC Yukon XL 2500 Exhaust Manifold, Driver Side Part Number: 12616285

$131.69 MSRP: $224.19You Save: $92.50 (42%)GMC Yukon XL 2500 Exhaust Manifold Part Number: 12677665

$230.69 MSRP: $362.98You Save: $132.29 (37%)Ships in 1-2 Business DaysGMC Yukon XL 2500 Exhaust Manifold, Driver Side Part Number: 12571679

GMC Yukon XL 2500 Exhaust Manifold, Driver Side Part Number: 12557287

GMC Yukon XL 2500 Exhaust Manifold, Driver Side Part Number: 12555621

GMC Yukon XL 2500 Exhaust Manifold

Want to cut long-term maintenance and repair costs? Choose OEM Exhaust Manifold. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Yukon XL 2500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Yukon XL 2500 Exhaust Manifold includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Yukon XL 2500 Exhaust Manifold Parts Questions & Experts Answers

- Q: How to replace the left exhaust manifold on 4.8L, 5.3L, and 6.0L engines on GMC Yukon XL 2500?A:The replacement process of the left Exhaust Manifold for 4.8l, 5.3l, and 6.0l engines begins with Ignition Coil and Spark Plug removal before vehicle elevation and support. Begin by taking out the Exhaust Manifold pipe nuts followed by lowering the vehicle to reach the Exhaust Manifold bolts and manifold alongside its gasket which needs removal before disposal. The installer will detach the Exhaust Manifold heat shield bolts and shield when required. You must inspect the Exhaust Manifold and clean it before reuse when keeping the existing manifold. During installation tighten the bolts of the Exhaust Manifold by torquing them to 9 nm (80 inch lbs.) after correctly reattaching the heat shield and its bolts to the Exhaust Manifold. Vehicle emissions together with the on-board diagnostics (OBD) ii system performance depend on precise torque adjustment of Exhaust Manifold bolts during installation. There should be no debris or threadlocking material present inside the Exhaust Manifold bolt hole threads of the cylinder head. Avoid using sealant on the first three bolt threads. Apply threadlocking band gm p/n 12345493 (equivalent to Canadian P/N 10953488) with a 5 mm (0.2 inch) width at the bolts' threads of the Exhaust Manifold. The Exhaust Manifold should be installed with fresh gasket and bolts according to this procedure: start by tightening the center bolts to 15 nm (11 ft. Lbs.), then move to the side-to-side alternation and finish with a final stage of 25 nm (18 ft. Lbs.). Use a flat punch to bend the exposed Exhaust Manifold Gasket edge located at the rear of the left cylinder head. Reposition the vehicle to install Exhaust Manifold pipe nuts that should be tightened to 50 nm (37 ft. Lbs.) after which you should lower the vehicle and replace the spark plugs and ignition coils.