ChevyParts

My Garage

My Account

Cart

OEM Saturn Hydraulic Hose

Brake Hydraulic Line- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

88 Hydraulic Hoses found

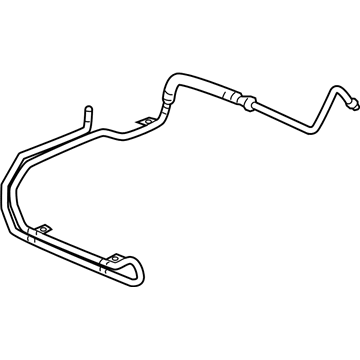

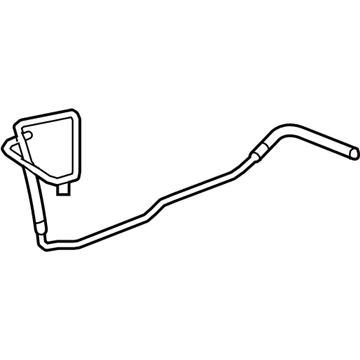

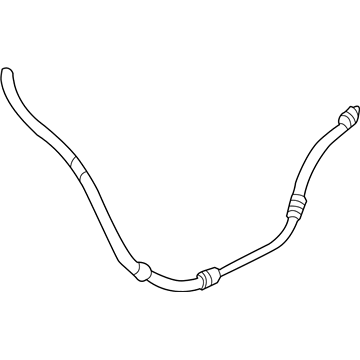

Saturn Power Steering Cooler Part Number: 15283101

$81.69 MSRP: $129.70You Save: $48.01 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose Assembly-Power Steering Fluid Cooling; Power Steering Hose; Power Steering Return Hose; Cooling Pipe; Hose, Steering Fluid Cooler

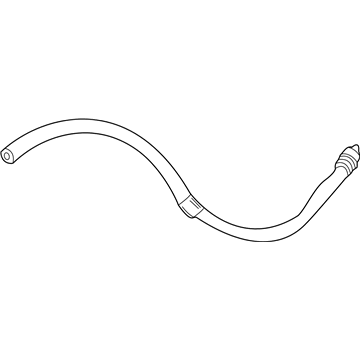

Saturn Power Steering Return Hose Part Number: 9191634

$15.44 MSRP: $25.44You Save: $10.00 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose Assembly, Power Steering Gear Outlet; Power Steering Hose; Return Hose; Hose, Steering Gear Oil Return

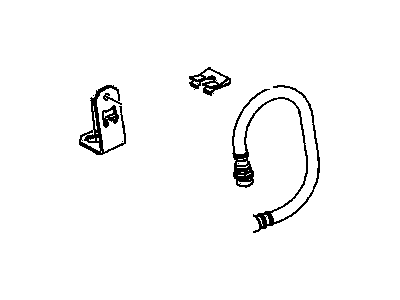

Saturn Flex Hose, Driver Side Part Number: 21011781

$20.06 MSRP: $31.76You Save: $11.70 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Driver Side

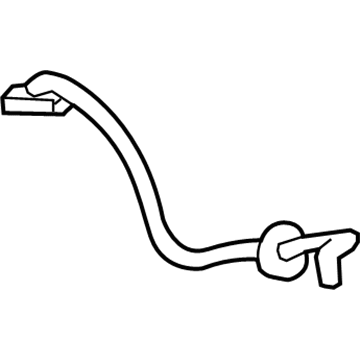

Saturn Flex Hose Part Number: 96625921

$25.86 MSRP: $46.81You Save: $20.95 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Rear Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Rear

Saturn Flex Hose, Front Passenger Side Part Number: 15899072

$29.76 MSRP: $53.85You Save: $24.09 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Passenger Side

- Replaces: 10305084, 15817953

Saturn Flex Hose, Driver Side Part Number: 84068674

$24.50 MSRP: $45.98You Save: $21.48 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Driver Side

- Replaces: 25903682, 15914568, 23240856, 22910276

Saturn Flex Hose, Passenger Side Part Number: 84068673

$30.62 MSRP: $57.47You Save: $26.85 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Passenger Side

- Replaces: 15914569, 25903683, 22910277, 23240857

Saturn Hydraulic Lines Part Number: 12576357

$86.20 MSRP: $135.02You Save: $48.82 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pipe-Clutch Actuator Cylinder; Hydraulic Hose; Clutch Hose; Clutch Line

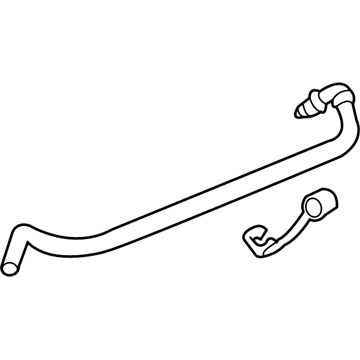

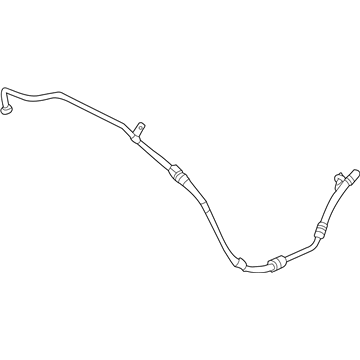

Saturn Power Steering Return Hose Part Number: 22915139

$61.69 MSRP: $105.05You Save: $43.36 (42%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose Assembly-Power Steering Gear Outlet; Power Steering Hose; Lower Return Line; Hose, Steering Gear Oil Return

- Replaced by: 19436425

Saturn Pressure Hose Part Number: 19151428

$49.49 MSRP: $78.59You Save: $29.10 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Steering Gear Oil Return; Power Steering Hose; Power Steering Return Hose

Saturn Power Steering Return Hose Part Number: 9191939

$35.65 MSRP: $58.72You Save: $23.07 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose Assembly, Power Steering Gear Inlet; Power Steering Hose; Return Hose; Hose, Steering Gear Oil Return

Saturn Power Steering Cooler Part Number: 15777213

$100.57 MSRP: $159.65You Save: $59.08 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose Assembly-Power Steering Fluid Cooling; Power Steering Hose; Power Steering Return Hose; Cooling Pipe; Hose, Steering Fluid Cooler

- Replaced by: 19540437

Saturn Power Steering Pressure Hose Part Number: 24409007

$63.32 MSRP: $99.19You Save: $35.87 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Hose, Steering Gear Oil Pressure; Power Steering Hose; Pressure Hose; Hose, Steering Gear Oil Return

Saturn Flex Hose, Passenger Side Part Number: 21011782

Product Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Hose; Brake Line

- Position: Passenger Side

Saturn Flex Hose, Rear Driver Side Part Number: 19366742

Product Specifications- Other Name: Hose Assembly, Rear Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Rear Driver Side

- Replaces: 19331548, 22720042

Saturn Power Steering Return Hose Part Number: 15942160

Product Specifications- Other Name: Hose Assembly-Power Steering Fluid Reservoir Inlet; Power Steering Hose; Inlet Hose; Hose, Steering Gear Oil Return

Saturn Flex Hose, Front Driver Side Part Number: 22667533

Product Specifications- Other Name: Hose Assembly-Front Brake; Hydraulic Hose; Brake Hose; Brake Line; Hose, Hydraulic Brake

- Position: Front Driver Side

Saturn Brake Hose Part Number: 13136715

Product Specifications- Other Name: Hose, Hydraulic Brake; Hydraulic Hose; Brake Line

- Position: Front

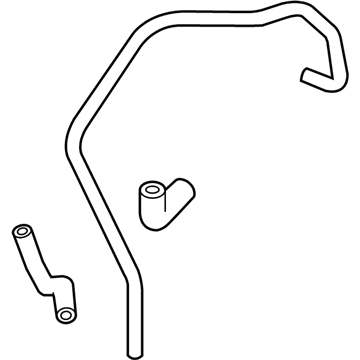

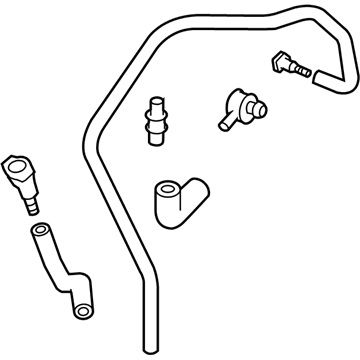

Saturn Pipe Part Number: 90541023

$21.24 MSRP: $37.91You Save: $16.67 (44%)Product Specifications- Other Name: Pipe, Power Brake Booster Vacuum; Pipe, Vacuum Power Brake

Saturn Pipe Kit Part Number: 94713563

Product Specifications- Other Name: Pipe, Power Brake Booster Vacuum; Pipe, Vacuum Power Brake

| Page 1 of 5 |Next >

1-20 of 88 Results

Saturn Hydraulic Hose

Choose OEM Hydraulic Hose, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Saturn's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsGiant.com, you'll find it easy to get top-quality OEM Saturn Hydraulic Hose. You can shop at highly competitive prices and protect your budget. All our genuine Saturn parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Saturn Hydraulic Hose feeds fluid under pressure between parts of the engine in a very tough and flexible manner to ensure that critical systems remain responsive on all drives. The innovative nature of Saturn resulted in such characteristics as the introduction of the dent-resistant plastic panels on the body, lost-foam cast engine blocks which reduced the weight and the high durability paint process, which was meant to ensure that cars remained looking and running good. Since 1991, only buyers have had a hassle-free experience, no haggle, no hassle pricing, owner events which the owners like doing, and a close-knit community surrounding the badge, which made buying a Saturn more than a purchase and became a brand that acquired a loyal following. A Saturn Hydraulic Hose is a strengthened hose that directs under high pressure hydraulics that will make steering, brakes and transmissions respond immediately. Prior to the installation of any Hydraulic Hose, inspect pressure limits, decommission and depressurize the system, evaluate the route, cut clean, brush off, and blow out debris. Install slide on fittings or crimp ferrules, and lightly oiled seals, tighten using a wrench to the recommended torque, and ensure that the hose does not get twisted or kinked. Install Hydraulic Hose around curves that conform to bend radius requirements, avoid sharp edges, heat, and moving components, install clamps or sleeves where rubbing may take place, and allow free movement due to vibration. Complete with the pressurization process and observe any leakage and re-torque the connections after short run-in period.