ChevyParts

My Garage

My Account

Cart

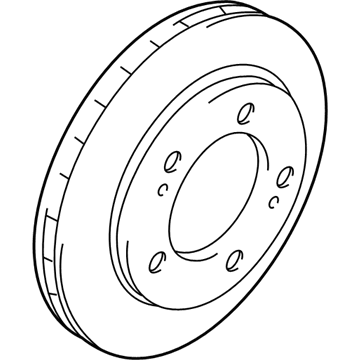

OEM 2000 Chevrolet Tracker Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Brake Disc found

2000 Chevrolet Tracker Rotor Part Number: 30024673

Product Specifications- Other Name: Rotor, Front And Rear Wheel Brake; Disc Brake Hardware Kit; Brake Rotor

- Position: Front

- Item Weight: 12.30 Pounds

- Item Dimensions: 13.0 x 12.4 x 3.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 30024673

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2000 Chevrolet Tracker Brake Disc

With a comprehensive array of OEM 2000 Chevrolet Tracker Brake Disc, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2000 Chevrolet Tracker Brake Disc are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2000 Chevrolet Tracker Brake Disc Parts and Q&A

- Q: How to Replace the Brake Disc on 2000 Chevrolet Tracker?A: Transferring two-thirds of brake fluid from the master cylinder reservoir using a siphon tool is the first step towards replacing the Brake Disc. First lift the vehicle. After that take off both tire and wheel assembly. Clamp the c tool onto both caliper and outer pad before tightening down until the piston touches bottom. Take off two mounting bolts first, along with the caliper and caliper bracket unit. Raise the combined parts from the disc keeping the flexible brake hoses from supporting the brake components to avoid damage. Secure the caliper-unit with wire to safeguard brake hoses from harm during work. Check the Brake Disc for changes in depth across its surface plus side wobble and wear signs. Use two 8 mm bolts to aid removal of the Brake Disc from its Wheel Hub. Install the new Brake Disc by setting it over the hub according to proper fastener procedures. Install the caliper bracket assembly by tightening its 2 mounting bolts to 85 nm (61.5 foot-pounds). Put back the tire and wheel set then put the vehicle down while filling the master cylinder tank. Release the Brake Pedal and activate the engine while pushing the pedal multiple times for bracket piston positioning.