ChevyParts

My Garage

My Account

Cart

OEM 2003 Chevrolet Suburban 1500 A/C Hose

Air Conditioning Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 A/C Hoses found

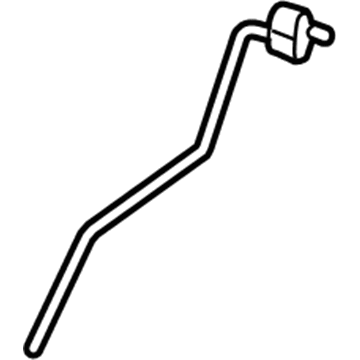

2003 Chevrolet Suburban 1500 Tube Part Number: 52468304

$7.41 MSRP: $13.92You Save: $6.51 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tube, Air Conditioner Blower Motor Cooling; A/C Refrigerant Liquid Hose; A/C Hose; Tube, A/C Blower Motor Cooling; Tube, Heater Motor Cooling; Tube, Heater Blower Motor

- Item Weight: 0.70 Pounds

- Item Dimensions: 5.3 x 2.7 x 1.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52468304

- Warranty: This genuine part is guaranteed by GM's factory warranty.

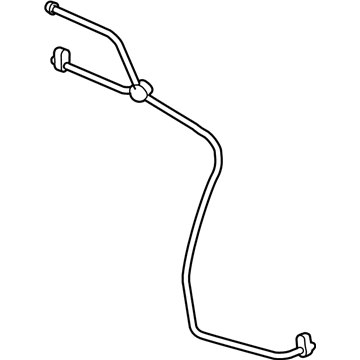

2003 Chevrolet Suburban 1500 A/C Line Part Number: 15708750

$94.18 MSRP: $193.54You Save: $99.36 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Evaporator Tube; A/C Refrigerant Liquid Hose; A/C Hose; Tube, A/C Evaporator

- Item Weight: 3.20 Pounds

- Item Dimensions: 46.8 x 9.7 x 9.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 15708750

- Warranty: This genuine part is guaranteed by GM's factory warranty.

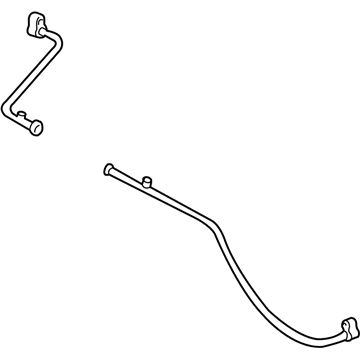

2003 Chevrolet Suburban 1500 A/C Line Part Number: 19418536

$59.73 MSRP: $122.76You Save: $63.03 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tube Assembly, A/C Evaporator; A/C Refrigerant Liquid Hose; A/C Hose; Pressure Line; Tube, A/C Evaporator

- Replaces: 15831686, 15785056, 15038861, 15708749

- Item Weight: 3.20 Pounds

- Item Dimensions: 49.0 x 6.1 x 6.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 19418536

- Warranty: This genuine part is guaranteed by GM's factory warranty.

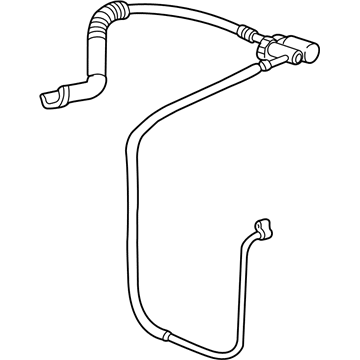

2003 Chevrolet Suburban 1500 A/C Hose Part Number: 15134454

$93.59 MSRP: $192.34You Save: $98.75 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: AC Hose; A/C Refrigerant Liquid Hose; A/C Hoses

- Replaced by: 22876351

- Item Weight: 1.00 Pounds

- Item Dimensions: 30.2 x 14.8 x 4.6 inches

- Condition: New

- SKU: 15134454

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 Chevrolet Suburban 1500 Evaporator Tube Part Number: 15043169

Product Specifications- Other Name: Hose Assembly-Auxiliary A/C Evaporator; A/C Refrigerant Liquid Hose; A/C Hose

- Replaced by: 19330875

- Item Weight: 3.80 Pounds

- Item Dimensions: 159.6 x 31.3 x 7.6 inches

- Condition: New

- SKU: 15043169

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 Chevrolet Suburban 1500 A/C Hoses Part Number: 19303190

Product Specifications- Other Name: Hose, Air Conditioner Refrigerant (Metal And Rubber Sections); A/C Refrigerant Liquid Hose; A/C Hose; Hose, A/C Compressor And Condenser

- Replaces: 15195651, 15065472

- Item Weight: 2.40 Pounds

- Item Dimensions: 167.5 x 31.9 x 8.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 19303190

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 Chevrolet Suburban 1500 A/C Hose Part Number: 19303128

Product Specifications- Other Name: Hose Assembly, A/C Accumulator; A/C Refrigerant Liquid Hose; A/C Hoses; Hose, A/C Compressor And Condenser

- Replaces: 15043171, 15757340, 15043172, 15134460, 15195652, 15065473, 15757341

- Item Weight: 1.80 Pounds

- Item Dimensions: 17.3 x 14.8 x 5.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 19303128

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 Chevrolet Suburban 1500 A/C Hose Part Number: 15187285

Product Specifications- Other Name: Evaporator Outlet Hose; A/C Refrigerant Liquid Hose; A/C Hoses; Suction Hose; Suction Line; Rear A/C Hose; Hose, A/C Compressor And Condenser

- Replaces: 15708733

- Item Weight: 2.30 Pounds

- Item Dimensions: 36.4 x 8.2 x 4.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 15187285

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 Chevrolet Suburban 1500 A/C Hose Part Number: 15187280

Product Specifications- Other Name: Hose Assembly-A/C Condenser; A/C Refrigerant Liquid Hose; A/C Hoses; Hose & Tube Assembly; Front A/C Hose

- Replaced by: 15873053

- Item Weight: 1.00 Pounds

- Item Dimensions: 23.3 x 14.7 x 9.5 inches

- Condition: New

- SKU: 15187280

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2003 Chevrolet Suburban 1500 A/C Hose

With a comprehensive array of OEM 2003 Chevrolet Suburban 1500 A/C Hose, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2003 Chevrolet Suburban 1500 A/C Hose are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2003 Chevrolet Suburban 1500 A/C Hose Parts Questions & Experts Answers

- Q: How to service and repair A/C Hose pipes using the A/C Line Repair Kit (J 41425) on 2003 Chevrolet Suburban 1500?A: The A/C Line Repair Kit (J 41425) serves to address rub-through, collision damage and leakage in the system for heater and A/C pipe service and repair operations. You need to maintain correct minimum length in the straight line portions on both sides during the process of sectioning the rear A/C or heater lines. When fixing straight heater or A/C lines you need to recover or drain the cooling fluids respectively. Begin by elevating the vehicle before you find the damaged area and obtain a suitable replacement line. A tubing cutter should trim away the damaged part while the new line needs to reach the same dimensional length. The user must utilize the cleaning pad from the A/C Line Repair Kit (J 41425) to remove burrs and grease while ensuring the ends stay 19 mm (0.75 in) clean. The sealing process begins with LOK prep sealant and requires one drop of sealing compound (J 41425-3) on each end before inserting the line ends into the LOK fitting. Twist the fitting one complete rotation to distribute the sealing compound before placing the appropriate LOK fitting jaws on the tool (J 41425-1) and position it over the LOK connectors to ensure their position in the counter bore. The tool operator should use the provided 3/8 inch breaker bar to hold the LOK fitting tool while turning the forcing screw until the connector collars settle onto the center shoulder. Release the forcing screw before taking out the tool and check that the LOK fittings have been set correctly. Rephrase the procedure for the opposing A/C line end before lowering the vehicle and perform coolant refilling operations followed by the repair procedure for the AC system if necessary. Line sectioning repair procedures require the same steps while implementing multi-line splice stagger and ensuring all replacement lines have equivalent lengths.