ChevyParts

My Garage

My Account

Cart

OEM Buick LeSabre Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Fuel Rails found

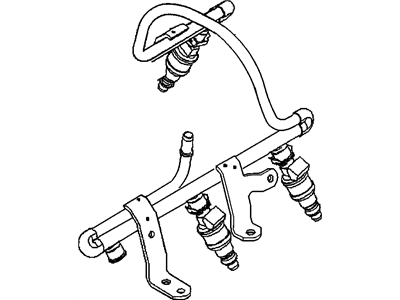

Buick LeSabre Fuel Rail Part Number: 24503754

Buick LeSabre Fuel Rail Part Number: 24503541

Buick LeSabre Fuel Rail Part Number: 17113198

Buick LeSabre Fuel Rail Part Number: 12587077

Buick LeSabre Fuel Rail

Want to cut long-term maintenance and repair costs? Choose OEM Fuel Rail. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick LeSabre parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick LeSabre Fuel Rail includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Buick LeSabre Fuel Rail Parts and Q&A

- Q: How to replace the fuel rail assembly on Buick LeSabre?A:A replacement of the Fuel Rail assembly begins with releasing fuel pressure from the system before cleaning all Fuel Rail components and connections. You must detach the vacuum line from the Fuel Pressure Regulator while pulling out the fuel feed pipes and return pipes from the Fuel Rail tubes. After pulling up the lock release on the Fuel Injector connectors the lock tab can be depressed to lift the connectors away from the fuel injectors. Raise each injector with the Fuel Injector removal tool (J 43013) while being cautious about the procedure. Use equal pressure when extracting the Fuel Rail from both sides. Installation requires proper positioning of the Fuel Injector o-rings where the black o-ring stays toward the top and the brown o-ring faces downward. Install the Fuel Rail assembly on the Intake Manifold then seat all fuel injectors manually after applying a little motor oil to their o-rings. Fasten the Fuel Rail hold-down bolts while torquing them to 10 n.m (89 lb in). Lock the connectors by pushing down on the release lever. After that install the fuel feed and return pipes onto the tubes of the Fuel Rail. Submit the vacuum line to the Fuel Pressure Regulator after reconnecting it followed by the ignition coil wire installation and fuel fill cap tightening and negative Battery Cable connection. A leak inspection should be conducted by turning the ignition on for two seconds followed by ten seconds of off time and then two more seconds of ignition until any fuel leaks are located before putting in the fuel injection sight shield.

- Q: What precautions should be taken when servicing the fuel rail assembly on Buick LeSabre?A:Service personnel must take precautionary measures to shield the Fuel Rail assembly against contaminants while performing maintenance because they need to install caps on the fittings and plugs on the holes. First release the fuel pressure present in the fuel system. The service begins with Fuel Rail connection cleaning before the fuel feed pipes and return pipes and their hoses from the Fuel Pressure Regulator and Throttle Body are successfully detached. Moving on, disconnect the Ignition Coil wires from their coils while taking off the electrical connectors from the Fuel Injectors. To proceed disconnect the Fuel Rail holding bolts then extraction of the Fuel Rail using identical pressure on both sides. Use proper orientation when installing the o-rings where the black o-ring fits into the upper slot and brown o-ring fits into the lower slot unless the colors differ. After installing the Fuel Rail assembly onto the Intake Manifold users should seat the fuel injectors manually while also applying clean motor oil to the Fuel Injector o-rings before replacing all new components o-rings. Connect the Fuel Rail hold-down bolts and torque them to 10 nm (7 lb ft). The first installation task involves connecting electrical connectors to fuel injectors before adding fuel feed and return pipes to the Fuel Rail, followed by a vacuum hose to the Fuel Pressure Regulator and vacuum hoses to the Throttle Body alongside Ignition Coil wire installation to ignition coils. You should install the Fuel Injector sight shield at the end of the installation process.