ChevyParts

My Garage

My Account

Cart

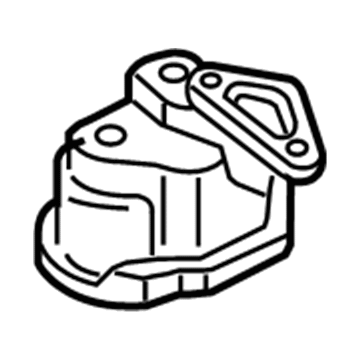

OEM Buick Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

33 Oil Pumps found

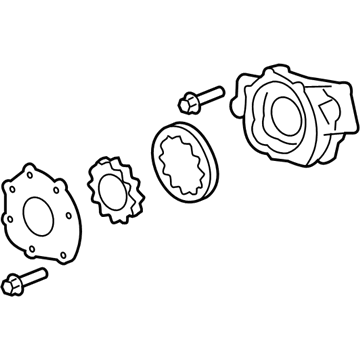

Buick Oil Pump Part Number: 93427692

$128.19 MSRP: $201.71You Save: $73.52 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump, Oil; Water Pump; Pump Assembly; Pump, Engine Oil Pump

- Replaces: 12555884, 03848907, 3848907, 12555284

Buick Oil Pump Part Number: 12705142

$127.48 MSRP: $200.53You Save: $73.05 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump, Engine Oil Pump; Oil Pump Repair Kit

Buick Oil Pump Part Number: 55514237

$466.14 MSRP: $736.76You Save: $270.62 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pump, Engine Oil Pump; Oil Pump Repair Kit

Buick Oil Pump Part Number: 89017753

$138.57 MSRP: $189.71You Save: $51.14 (27%)Product Specifications- Other Name: Pump, Oil; Oil Pump Repair Kit; Pump, Engine Oil Pump

Buick Oil Pump Part Number: 12706965

$132.11 MSRP: $224.91You Save: $92.80 (42%)Product Specifications- Other Name: Pump, Engine Oil Pump

- Replaces: 12674266, 12688727, 12666334, 12706720, 12666331

Buick Oil Pump Part Number: 12518877

Product Specifications- Other Name: Gear, Engine Oil Pump; Oil Pump Repair Kit; Gerotor Assembly; Pump Kit, Engine Oil Pump

Buick Oil Pump Part Number: 12555384

Product Specifications- Other Name: Pump, Engine Oil Pump; Oil Pump Repair Kit

- Replaces: 03539057, 3539057

Buick Oil Pump Part Number: 90169113

Product Specifications- Other Name: Pump, Engine Oil; Oil Pump Repair Kit; Pump, Engine Oil Pump

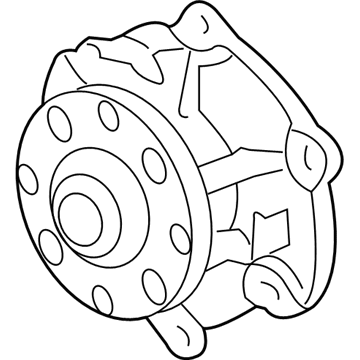

Buick Water Pump Part Number: 12566029

Product Specifications- Other Name: Pump, Water; Oil Pump

Buick Oil Pump Part Number: 22525287

Product Specifications- Other Name: Pump Assembly; Oil Pump Repair Kit; Pump, Engine Oil Pump

Buick Oil Pump Part Number: 25518783

Product Specifications- Other Name: Oil Pump Repair Kit

Buick Oil Pump Part Number: 12337257

Product Specifications- Other Name: Pump Kit, Oil (Overhaul) (Free Of Asbestos); Oil Pump Repair Kit

Buick Oil Pump Part Number: 12337253

Product Specifications- Other Name: Pump Kit, Engine Oil Pump; Oil Pump Repair Kit

Buick Oil Pump Part Number: 22524576

Product Specifications- Other Name: Pump, Engine Oil Pump; Oil Pump Repair Kit

Buick Oil Pump Part Number: 10118640

Product Specifications- Other Name: Pump, Engine Oil Pump; Oil Pump Repair Kit

Buick Oil Pump Part Number: 22524583

Product Specifications- Other Name: Pump, Engine Oil Pump; Oil Pump Repair Kit

Buick Oil Pump Part Number: 14086060

Product Specifications- Other Name: Pump, Engine Oil Pump; Oil Pump Repair Kit; Pump Kit, Engine Oil Pump

Buick Oil Pump Part Number: 88984189

Product Specifications- Other Name: Pump, Engine Oil Pump; Oil Pump Repair Kit

- Replaces: 10209660

Buick Oil Pump Part Number: 12363188

Product Specifications- Other Name: Pump, Engine Oil Pump; Oil Pump Repair Kit

- Replaces: 24571299

Buick Oil Pump Part Number: 94657310

Product Specifications- Other Name: Pump, Engine Oil Pump; Oil Pump Repair Kit

| Page 1 of 2 |Next >

1-20 of 33 Results

Buick Oil Pump

Choose OEM Oil Pump, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Buick's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsGiant.com, you'll find it easy to get top-quality OEM Buick Oil Pump. You can shop at highly competitive prices and protect your budget. All our genuine Buick parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Buick Oil Pump Parts and Q&A

- Q: How to Service and Repair the Oil Pump on Buick LaCrosse?A:Begin by taking out the case side cover to start the Oil Pump replacement process. Disconnect solenoid valves (315A/315B/322/334/440) tfp manual valve position switch (395) and temperature sensor (391) connections using a flat-tooth tool while keeping bolt (205) that binds Oil Pump pieces intact. After unplugging all electrical connectors attach to the Oil Pump you should now remove the Oil Pump bolts (206, 207). Once freed securely pull out the Oil Pump (200) from Valve Body (300). .align the Oil Pump (200) with Valve Body (300) openings before inserting Oil Pump bolts (206, 207). Secure the m6 x 1.0 x 85 bolts (207) to 12 nm torque level and the m6 x 1.0 x 95 bolts (206) to 16 nm torque level. Rejoin electrical wires to the control valves beginning with 440 at solenoid 315a while closing with temperature probe 391 and valve position switch 395.

- Q: How to replace the oil pump in the 4T65-E automatic transmission on Buick Lucerne?A:Before disassembling the Oil Pump in the 4t65-e automatic transmission, start with removing the case side cover. Then remove the Oil Pump bolts (230, 231) and Oil Pump (200) from the Valve Body (300). Inspect and clean Oil Pump, making sure it is in a good condition. To install, mount the Oil Pump (200) back on the Valve Body (300) and install the Oil Pump bolts (230, 231). Torque the nine (231) m6 x 1.0 x 85 bolts to 12 nm (106 lb in) and the two (230) m6 x 1.0 x 95 bolts to 16 nm (12 lb ft). Experts recommend resetting the transmission adaptive pressure (TAP) values through the scan tool because it will clear all learned values, whereby the Engine Control Module (ECM), powertrain control module (PCM), or transmission control module (TCM) will have to learn all tap values, and this will impact the transmission performance. Lastly, re-cover the side cover of the case.