ChevyParts

My Garage

My Account

Cart

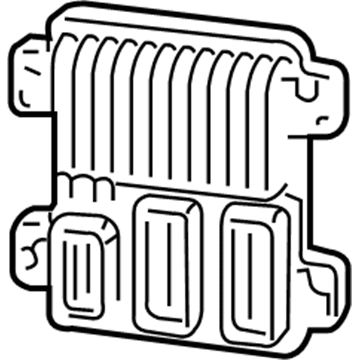

OEM Cadillac Engine Control Module

Engine Control Computer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

78 Engine Control Modules found

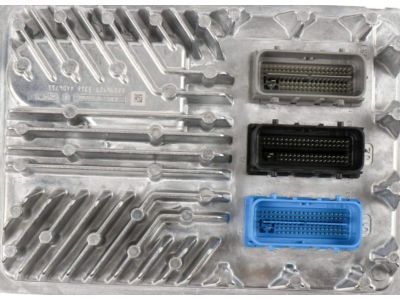

Cadillac ECM Part Number: 12692068

$279.58 MSRP: $566.80You Save: $287.22 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/2ND Mpu) E92 Service ECM, 5 Byt; Engine Control Module

- Replaced by: 12704476

Cadillac ECM Part Number: 12692067

$278.29 MSRP: $564.16You Save: $285.87 (51%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/2ND Mpu) E92 Service ECM 2-Byte; Engine Control Module

- Replaced by: 12704477

Cadillac ECM Part Number: 12623327

$272.19 MSRP: $552.85You Save: $280.66 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module, Emission Control System; Engine Control Module

- Replaces: 12614423

Cadillac ECM Part Number: 88999120

$116.61 MSRP: $217.22You Save: $100.61 (47%)Product Specifications- Other Name: Module Assembly, Engine Control (Remanufacture); Engine Control Module; Module, Emission Control System

- Replaces: 01226462, 1226462

Cadillac ECM Part Number: 12668693

$254.35 MSRP: $477.67You Save: $223.32 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/2ND Mpu); Engine Control Module

- Replaced by: 12725784

Cadillac ECM Part Number: 88999202

$218.56 MSRP: $408.66You Save: $190.10 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Assembly, Powertrain Control (Remanufacture); Engine Control Module; Module, Emission Control System

- Replaces: 16207768

Cadillac ECM Part Number: 12725784

$266.30 MSRP: $477.67You Save: $211.37 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/2ND Mpu); Module, Emission Control System

- Replaces: 12668693, 12709199, 12679077, 12683347, 12687295

Cadillac ECM Part Number: 12659039

$234.37 MSRP: $476.02You Save: $241.65 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/2ND Mpu); Engine Control Module

- Replaced by: 12725663

Cadillac ECM Part Number: 12602801

$534.19 MSRP: $962.30You Save: $428.11 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module, Powertrain Control (P59)

- Replaced by: 89017749

Cadillac ECM Part Number: 12725787

$283.41 MSRP: $508.39You Save: $224.98 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/O Calibration); Module, Emission Control System

Cadillac PCM Part Number: 12678513

$333.65 MSRP: $624.14You Save: $290.49 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module, Emission Control System; Engine Control Module; ECM

- Replaces: 12633264

Cadillac PCM Part Number: 12667002

$248.14 MSRP: $504.00You Save: $255.86 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module, Emission Control System; Engine Control Module; ECM

Cadillac ECM Part Number: 88999124

$116.79 MSRP: $218.42You Save: $101.63 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Assembly, Engine Control (Remanufacture); Engine Control Module

- Replaces: 01226866, 1226866

Cadillac ECM Part Number: 12725415

$259.04 MSRP: $526.15You Save: $267.11 (51%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/O Calibration); Module, Emission Control System

- Replaces: 12718010

Cadillac ECM Part Number: 12703874

$290.42 MSRP: $520.94You Save: $230.52 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/O Calibration); Engine Control Module; Module, Emission Control System

- Replaced by: 12726539

Cadillac ECM Part Number: 12624927

$388.99 MSRP: $790.08You Save: $401.09 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/2ND Mpu); Engine Control Module; Module, Emission Control System

Cadillac ECM Part Number: 12729311

$263.18 MSRP: $741.02You Save: $477.84 (65%)Product Specifications- Other Name: Module Assembly-Engine Control (W/O Calibration); Module, Emission Control System

- Replaced by: 12740833

Cadillac ECM Part Number: 12629278

$258.14 MSRP: $463.04You Save: $204.90 (45%)Product Specifications- Other Name: Module, Emission Control System; Engine Control Module

- Replaces: 12611182

Cadillac ECM Part Number: 12723949

$188.07 MSRP: $337.34You Save: $149.27 (45%)Product Specifications- Other Name: Module Assembly-Engine Control (W/O Calibration); Module, Emission Control System

- Replaces: 24001956

Cadillac ECM Part Number: 12600940

$299.25 MSRP: $536.78You Save: $237.53 (45%)Product Specifications- Other Name: Module, Engine Control; Engine Control Module

| Page 1 of 4 |Next >

1-20 of 78 Results

Cadillac Engine Control Module

Want to cut long-term maintenance and repair costs? Choose OEM Engine Control Module. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac Engine Control Module includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Cadillac Engine Control Module Parts Questions & Experts Answers

- Q: How to remove and install the engine control module (ECM) on Cadillac CTS?A:Begin the ECM removal by switching off ignition to defend its internal components. You must remove the screw which maintains the connection of the engine control module ground wire to the ECM. Widen the release levers to open position while disconnecting ECM connectors from the ECM device and avoid handling the pins because electrostatic discharge can damage the system. The ECM bracket should be released by removing its attached nuts to extract the ECM from its position. Position the ECM to the ECM bracket when the ignition is off and attach the nuts while tightening them to 8 N.m (71 lb in). Let the harness connectors align with the ECM connectors before manually pressuing them inside their positions during lever movement into locking position. Follow the installation steps to fix the ECM ground wire with its securing screw to the ECM while tightening it to 4.5 N.m (40 lb in). Program the ECM with the Service Programming System (SPS) and apply theft deterrent system programming if you use an ECM which came from a different vehicle. The new ECM from GM will immediately acquire the fuel continue password once the programming phase finishes. Using SPS, the theft deterrent system components require programming when the ECM comes from another vehicle. To learn the current vehicle's fuel continue password, you must follow either the 10-minute procedure or the 30-minute procedure after programming. The idle learn procedure must be executed as the last step.

- Q: What is the purpose of the Service Programming System (SPS) in programming the Engine Control Module on Cadillac Escalade?A:The service programming system (SPS) lets technicians program control modules by using the data link connector (DLC) while they access diagnostic information that dtcs and data through the same serial data circuit as scanning tools. A control module maintains two memory types including electrically erasable programmable read only memory (EEPROM) that stores information like vehicle identification number (VIN) and crankshaft variation learned position and control module security data among others and flash read only memory for larger storage capacity that programmer completely replaces during programming operations. Programming with tech 2 uses remote and pass thru methods while obpa enables remote and off-board pass thru methods but needs the control module in place according to the specified protocols. The vehicle demands a battery voltage range from 12 to 16 volts with no charging problems before programming and all systems loading the battery must be disabled including daytime running lights and hvac systems and engine cooling fans. A programming session needs the Ignition Switch set precisely as the scan tool indicates and requires firm rs-232 cable connections and all dlc connections to remain stable. Tool harness disturbance during programming should be avoided to prevent failures and protect the hardware. The powertrain modifications from programming cause the control module to perform learn procedures for fuel trim correction along with idle air control (IAC) learned position and automatic transmission shift adapts. Replacement of a control module will require service personnel to perform a crankshaft variation learn procedure together with engine oil life reset procedure and idle learn procedure while following the inspection/maintenance complete system set procedure, vehicle theft deterrent password learn procedure, and throttle position (TP) sensor learn procedure.

- Q: What precautions should be taken during Engine Control Module service on Cadillac XLR?A:Engine control module (ECM) service requires ECM component replacement or EEPROM programming and when replacement is needed check for the correct part selection. The process of installing and removing control module connectors together with power disconnects must always have the ignition set to OFF to safeguard the internal components from damage. Never let the metal case of the control module touch battery voltage during service since this will lead to damage. Guard against electrostatic damage by refraining from touching connector pins or soldered components of the circuit board and ensuring all dust and dirt is cleared from around the control module connector surfaces. An inspection of the control module connector gaskets will confirm their proper installation status to block contaminant access. Failure to record engine oil lifetime and automatic transmission fluid lifetime beforehand will cause default percentages to set engine oil change requirements at 5000 km (3,000 mi) and automatic transmission fluid requirements at 83000 km (50,000 mi) from the last change schedule. Begin by obtaining and writing down the remaining engine oil and automatic transmission fluid life with a scan tool before you take out the right front wheelhouse filler panel to disconnect the ECM electrical connectors and take off its fasteners. Installation requires users to place the ECM on the ECM bracket and fasten retaining fasteners to 3.0 N.m (27 lb in). Users must reconnect electrical connectors afterward then reinstall the right front wheelhouse filler panel. When installing a new ECM users must program it.