ChevyParts

My Garage

My Account

Cart

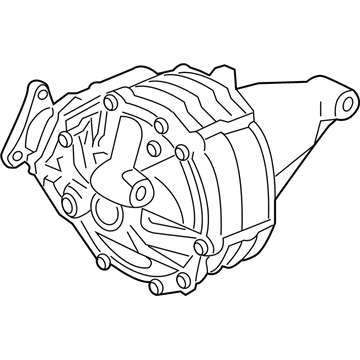

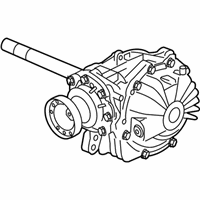

OEM Cadillac SRX Differential

Front Differential- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 Differentials found

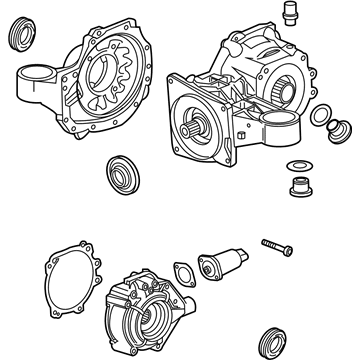

Cadillac SRX Differential Case Part Number: 19133287

$383.46 MSRP: $520.49You Save: $137.03 (27%)Cadillac SRX Carrier Part Number: 22896613

$2788.48 MSRP: $3605.01You Save: $816.53 (23%)Cadillac SRX Differential Carrier Part Number: 19178783

$248.03 MSRP: $1369.94You Save: $1121.91 (82%)Ships in 1-2 Business DaysCadillac SRX Differential Part Number: 22897038

$2149.65 MSRP: $2883.50You Save: $733.85 (26%)Cadillac SRX Differential Carrier Part Number: 25978162

Cadillac SRX Differential Assembly Part Number: 23221507

Cadillac SRX Differential Assembly Part Number: 23221505

Cadillac SRX Gear Assembly Part Number: 19259128

Cadillac SRX Carrier Assembly, Front Part Number: 25978168

Cadillac SRX Carrier Part Number: 25978164

Cadillac SRX Differential Carrier Part Number: 25978163

Cadillac SRX Differential Carrier Part Number: 25978161

Cadillac SRX Differential Carrier Part Number: 19181710

Cadillac SRX Differential Carrier Part Number: 19181709

Cadillac SRX Differential Carrier Part Number: 19178779

Cadillac SRX Differential Carrier Part Number: 19178776

Cadillac SRX Differential Carrier Part Number: 19133286

Cadillac SRX Carrier Assembly, Front Part Number: 25978167

$2141.91 MSRP: $2756.64You Save: $614.73 (23%)Cadillac SRX Differential Carrier Part Number: 25978166

$1678.94 MSRP: $2160.80You Save: $481.86 (23%)

Cadillac SRX Differential

Want to cut long-term maintenance and repair costs? Choose OEM Differential. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac SRX parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac SRX Differential includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

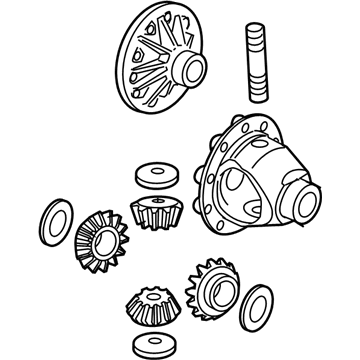

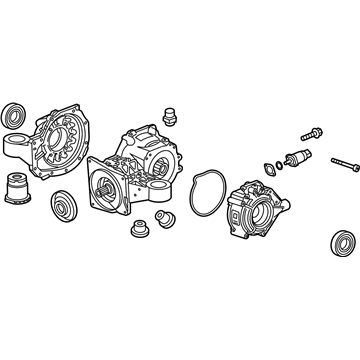

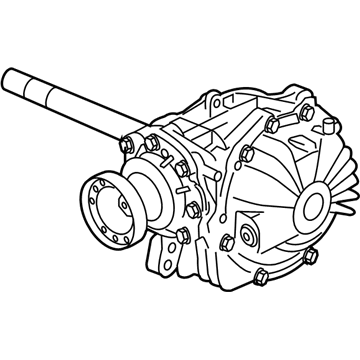

The Cadillac SRX Differential is one of the precious devices that are critical to the front-wheel drive-based mid-size luxury sport utility vehicle and contributing to the performance and variability of power-train a number of SRX models. This complex system enables the drive wheels to turn at different rpm which is essential when cornering and for getting the optimal grip of the road. The Cadillac SRX vehicles most commonly use the open differentials to split the torque equally between the wheels and at the same time, use the limited slip differentials (LSD) to boost tractions through regulating power in accordance to the condition of the wheels. It is most helpful in driving that is difficult, where it allows the Cadillac SRX to provide stability and consistently be at its optimal. The features of the differential are quite important in determining the SRX's handling so as to provide a feel of powerful and commanding drive. Cadillac SRX Differential requires fluid to help in its operations and any loss or even wear and tear may lead to its poor functioning hence needs regular checkups. The Cadillac SRX was first produced from 2003 to 2016 and it is regarded as one of the luxury cars and comes equipped with excellent safety features and comfort. The Cadillac SRX has the optimal market sales figures mainly due to a well-developed power train and a perfect differential system. Therefore, the Cadillac SRX is easily distinguishable on the automobile market and is the epitome of luxury, efficiency, and durability that comes with an innovative differential system.

Cadillac SRX Differential Parts Questions & Experts Answers

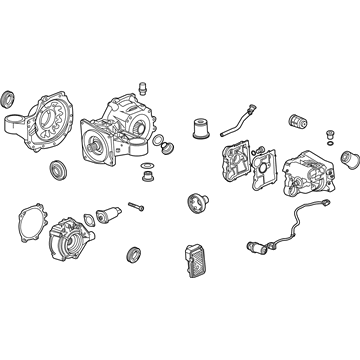

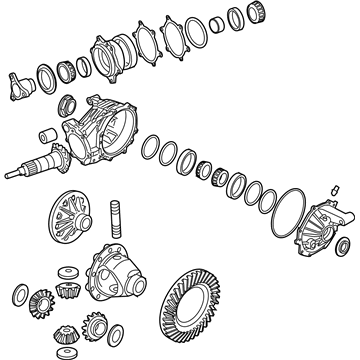

- Q: How to service and repair the differential case on Cadillac SRX?A:To service and repair the Differential case you first make sure that safety persons are used. Clean the Differential case in the solvent to check for chips, craks, bolt hole damage , unusual wear, grooves, scoring, damaged side bearing flanges, heat discoloration, wheard Differential pin bores. Additionally, inspect the gear for corrosion, heat discoloration, unusual wear or scoring in positions of the Differential pin bore, wear and coat removal, as well as scorings on Differential s pin side gear washers, scattering, and unusual wear in side gear splines on axle. Clean the pinion flange in the solvent and inspect for wear, pitting, or twisting of the splines and grooves or pitting on the sealing surface. Examine the bearing rollers and races for pitting, scoring, groove, excessive wear and heat discoloration which could be an indication of overload and improper lubrication; kip any parts that have been discoloured with heat. Check the damaged bearing cages , also clean the Differential carrier in solvent , check pinion housing bolt hole threads , also check carrier cover bolt hole threads , carrier cover sealing area , drain plug threads , and axle seal area , respectively. Clean oil passage between and in axle bearing cup bore so that surfaces are free and clean from nicks and burrs. The Differential Cover is then cleaned in solvent and examined for flow of oil between and in the axle cup bore, fill plug threads , o-ring groove, and cup and shim surfaces. Inspect the cover axle seal mounting surface and clean the pinion bearing housing in solvent and keep it air dry by blowing the oil from the holes behind the cups. Make sure that there are no nicks, burrs on the mating surface to prevent binding or clean the o-ring groove. Use the housing only if old bearings are being used, and newensions and spacer are actually a kit with it being pre-cut and not for field service.