ChevyParts

My Garage

My Account

Cart

OEM Cadillac SRX CV Joint

CV Joint Axle- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 CV Joints found

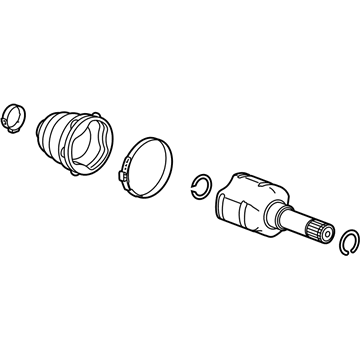

Cadillac SRX Outer CV Joint Part Number: 88957235

$141.09 MSRP: $222.00You Save: $80.91 (37%)Ships in 1-3 Business DaysCadillac SRX Inner CV Joint Part Number: 88957234

$120.22 MSRP: $189.16You Save: $68.94 (37%)Ships in 1-3 Business DaysCadillac SRX CV Joints Part Number: 88957231

$120.77 MSRP: $191.74You Save: $70.97 (38%)Ships in 1-2 Business DaysCadillac SRX Inner CV Joint, Rear Passenger Side Part Number: 20894138

$39.52 MSRP: $176.38You Save: $136.86 (78%)Ships in 1-2 Business DaysCadillac SRX Outer CV Joint Part Number: 88957237

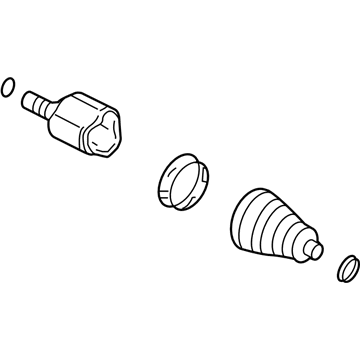

Cadillac SRX Inner CV Joint Part Number: 88957236

Cadillac SRX Inner CV Joint, Rear Driver Side Part Number: 20894137

Cadillac SRX Inner CV Joint, Front Driver Side Part Number: 20846067

Cadillac SRX Outer CV Joint, Inner Part Number: 20846061

Cadillac SRX Outer CV Joint, Front Part Number: 13296184

Cadillac SRX CV Joints Part Number: 88957233

Cadillac SRX CV Joints Part Number: 88957232

Cadillac SRX CV Joint

Want to cut long-term maintenance and repair costs? Choose OEM CV Joint. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac SRX parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac SRX CV Joint includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

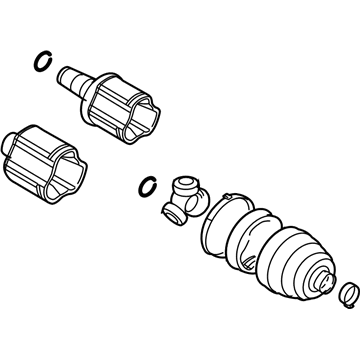

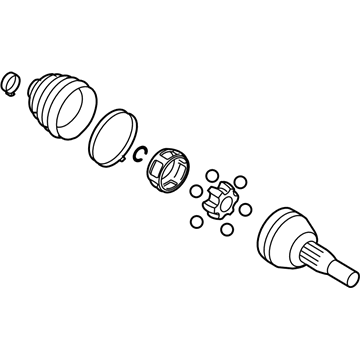

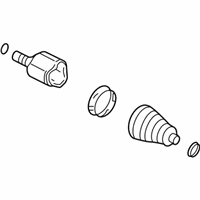

Among the Cadillac SRX Parts, one of the most crucial is the Cadillac SRX CV Joint which play a crucial role in how the mid-size luxury SUV from Cadillac performs and functions by allowing the transmission's power to be delivered to the drive wheels and flexibly adjust to movements of the suspension and wheels or steers. Thus, the Cadillac SRX CV Joint is known for its high durability, due to which the rotational speed of its part is constant, which is vitally important for the correct operation of the car. It is normal to find Rzeppa joints on the outer ends while plunging joints at the inner ends of Cadillac SRX models' axle shafts so that the vehicles can experience high articulation and adaptability in the suspension travel. It also comes in handy in improving on the overall performance of the Cadillac SRX not forgetting the aspect of safety since handling and control is made more stable. The rubber boots of the CV Joint must be intact to avoid the seepage of lubricant and ultimately failure of the joint therefore showing the need for constant maintenance. The Cadillac SRX is a luxury crossover SUV model, which has received outstanding ratings as a prime-seller vehicle in the United States of America within two generations between the years 2003 and 2016, that boast of their high quality original parts that include the CV Joint. In terms of safety, convenient and comfort, the Cadillac SRX is equipped with such gadgets as advanced safety technologies and exquisite interior. The ability to tow a large load and simultaneously its fuel efficiency adds to the attractiveness which makes the Cadillac SRX CV Joint an important factor that offers the consumer a powerful, safe and luxurious car experience.

Cadillac SRX CV Joint Parts and Q&A

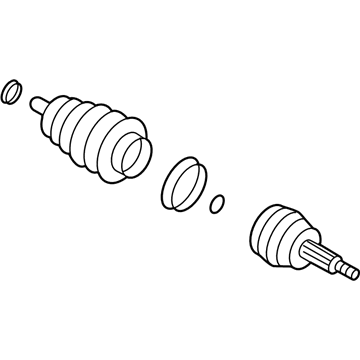

- Q: How to replace the CV Boot and CV Joint of the front outer drive shaft on Cadillac SRX?A:The first step for replacing front wheel drive shaft's outer joint and boot begins with removing the wheel drive shaft from its vehicle position. Place the drive Axle Shaft inside a soft-jawed vice while conserving the inboard and outboard boot from cutting to maintain the sealing surface and reduce constant velocity joint wear. A flat blade tool removes the boot clamp from the constant velocity (CV) joint and the boot before side cutters extract and dispose of the boot clamp from both components. Install new clamps instead. A block of wood and hammer allow users to extract the cv joint from the wheel drive shaft and then remove the boot from the wheel drive shaft. During boot installation place the boot onto the wheel drive shaft but make sure it fits correctly into the wheel drive shaft groove. The lubrication process should be split with one part placed in the cv joint boot and the remaining section placed in the cv joint itself. Position the wheel drive shaft cv joint using a hardwood block and a hammer before clamping the boot to the wheel drive shaft inboard then continuing with the boot to cv joint housing outboard clamp installation around the boot's whole circumference. The dt 35910 pliers need to tighten the clamp while you measure a gap of 2.15 mm (0.85 in) then apply the ch 48894 pliers to shut the boot clamp . Reposition the wheel drive shaft onto the bench vise after applying circular motion to the cv joint 4 to 5 times to achieve lubricant distribution before returning the wheel drive shaft to the vehicle.

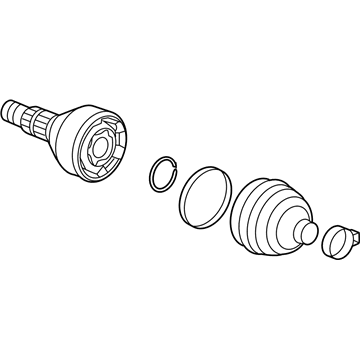

- Q: How to Service and Repair the CV Joint Boot on Cadillac SRX?A:To service and repair the constant velocity joint boot start from collecting necessary tools: j 42572 drive shaft seal clamp pliers. After the removal of the wheel drive shaft from the vehicle, take a shop towel and wrap it to put the Axle Shaft and then, place the wheel drive shaft horizontally on a bench vise. Remove and discard the large and small seal retaining clamps from the inner joint seal with the help of a side cutter or any other appropriate tool. Pull the seal off the inner joint outer race at the big diameter end and slide this seal away from the joint face. After that, take back the grease from inside race, cage and balls, afterwards, you can remove that inside joint from the Axle Shaft where you hold the inner joint housing horizontally and you placed a brass drift on the inner race and hit it gently on the inner race with a hammer to extract the Axle Shaft retaining clip. In this step, dispose of the Axle Shaft retaining ring and then pull off the seal from the Axle Shaft. The inner race, outer race, cage, balls, and exposed end of the Axle Shaft must then be cleaned with clean solvent, dried with only air, and inspected for damage or wear. For assembling, apply the grease from the service kit to the inner joint, approximately 60 percent of this into the inner part disturbing the ball tracks, balls, cage, and inner race, the remaining onto the bottom of the outer race. Wrap a shop towel around the Axle Shaft and fitting the wheel drive shaft horizontally in a bench vise and fitting a new small seal retaining clamp on the Axle Shaft, followed by a seal, finally a new retaining ring. Join the inner race splines with the Axle Shaft splines, compress the Axle Shaft ring spacer, press the end of the retaining ring into the Axle Shaft groove while at the same time firmly pressing the inner joint on the Axle Shaft. Place the hot tube inside the shaft and drive the inner joint onto the shaft using a wood block and hammer until it becomes fully seated. Position the small seal retaining clamp into the boot, click in on the seal and small retaining clamp to the boot groove of the wheel Axle Shaft. Upon crimping the small seal retaining clamp using the j 42572 until it forms a gap of 1 mm (0.039 in) at the base of the omega ohm shape. Fill the rest of the seal with the grease from the service kit, clamp the large seal retaining clamp onto the seal, and clamp it onto the outer race of the joint. Check the distance between the seal edges to be sure it is 86.85 mm (3.42 in) and check for the seal shape and damage and discard if necessary. Lastly, crimp the large seal retaining clamp using the j 42572 until you have a gap of 1-mm (0.039 in) along with that, inspect the inner joint for a smooth rotation while rotating wheel drive shaft four or five times then install the wheel drive shaft.