ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Impala Transmission Oil Cooler

Trans Oil Cooler- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Transmission Oil Coolers found

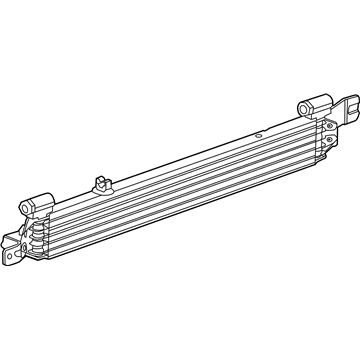

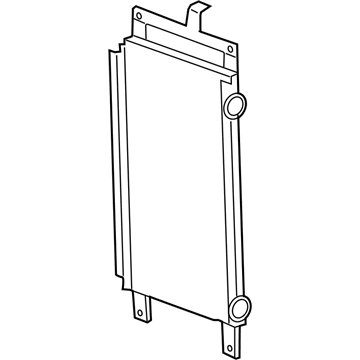

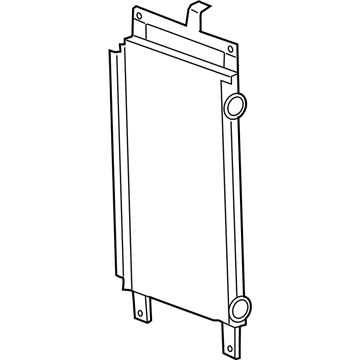

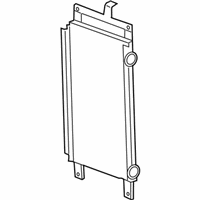

Chevrolet Impala Transmission Cooler Part Number: 22747163

$228.71 MSRP: $440.03You Save: $211.32 (49%)Ships in 1-2 Business DaysChevrolet Impala Transmission Cooler Part Number: 52484146

$15.73 MSRP: $124.96You Save: $109.23 (88%)Ships in 1-2 Business DaysChevrolet Impala Transmission Cooler Part Number: 23133113

$231.45 MSRP: $345.96You Save: $114.51 (34%)Chevrolet Impala Transmission Cooler Part Number: 52484142

Chevrolet Impala Transmission Cooler Part Number: 89018358

Chevrolet Impala Transmission Cooler Part Number: 19129783

Chevrolet Impala Transmission Oil Cooler

Want to cut long-term maintenance and repair costs? Choose OEM Transmission Oil Cooler. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Impala parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Impala Transmission Oil Cooler includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Impala Transmission Oil Cooler Parts and Q&A

- Q: What tools are required to service and repair the automatic transmission oil cooler on Chevrolet Impala?A:The following tools are required to service and repair the automatic Transmission Oil Cooler: oil cooler and line flusher (J 35944-A). Start with the removal of the oil cool & line flusher (J35944A) to treat it 0.6 liters (20 ounces) of flushing solution without overfilling. Replace the cap and increase the pressure in the unit to 550 - 700 kpa (80 - 100 psi). Attach a discharge hose to the transaxle outlet of the oil cooler pipe which feeds the bottom connection of the oil cooler and attach to an oil drain container, and hook the feed hose from the oil cooler and line flusher (J 35944-A) to the other oil cooler pipe. Make sure the water valve on oil cooler and line flusher (J 35944-A) is off then attach and open the water supply. If there is no flow in the cooler, do not proceed because the system may be plugged. Press the letter "t" to open the transaxle ports and then press the water valve for about 10 seconds to squirt transaxle fluid down, then return it to the "off" position and clip the discharge hose to a 5-gallon pail covered with a shop towel to keep bird spatter to a minimum. Turn the valve back on and pull the trigger together with the help of the given bale clip to pull down the trigger for two minutes flushing. Connect the air supply to the air valve on the oil cooler and line flusher (J 35944-A) for 3 -5 seconds every 15-20 seconds for a surging action for a full cleaning. After the trigger is turned out, tap off the water valve and disconnect hoses from the oil cooler pipes. Reconnect the hoses to the other pipes for a backflush and repeat the mixing and flushing step. Allow water to rinse for one minute, turn off the water supply and connect to the air supply to dry the system until no moisture is observed coming out from the discharge hose. Mount the oil drain container to the jack stands or ramp to put the jack stands under. Then reconnect the oil drain pipe to the cooler feed pipe, and the oil drain container to the cooler return pipe, then ensure it is held securely in that position with the container at the oil drain. Begin the engine after adding the transaxle with fluid and let it run for 30 seconds in order to clear the oil cooler of any traces of waiting moisture or not less of 1.9 liters (2 quarts). In case there is a low fluid flow, remove the feed line from the cooler and check if the flow is okay using a running engine and view the transaxle, cooler tubes, and the fittings as potential reasons. Repeat the flushing of the cooler if needed, detaching the discharge hose, attaching the cooler pipe, adjusting the fluid level, and checking for fluid leaks.

- Q: How to replace the Transmission Oil Cooler on Chevrolet Impala?A:Start by ensuring enough space exists between transaxle oil cooler pipes and hoses to stop damage or fluid leakage. You need to start by pulling out the upper radiator air baffle followed by unbolting the auxiliary transaxle oil cooler from the upper radiator support. Start by removing the lower radiator air baffle followed by removing auxiliary transaxle oil cooler bolts from the lower radiator support. Disconnect the inlet and outlet auxiliary Transmission Oil Cooler lines from their clips on the support structure and drop the auxiliary transaxle oil cooler down below the front bumper. Remove auxiliary transaxle cooler hoses from inlet and outlet ports before extracting the oil coolant unit from its location. To put the cooler back into the vehicle first connect the inlet and outlet auxiliary transaxle oil cooler hoses to the cooler before installation. Secure both inlet and outlet auxiliary Transmission Oil Cooler lines to their storage clips while paying attention to the fastener notice. Tighten the auxiliary transaxle oil cooler bolts at lower radiator support to 10 n.m (89 lb in) before reinstalling the lower radiator air baffle. Last, drive the auxiliary transaxle oil cooler bolt into the upper radiator support using 25 n.m (18 lb ft) of torque before installing the upper radiator air baffle and adjusting the fluid level.