ChevyParts

My Garage

My Account

Cart

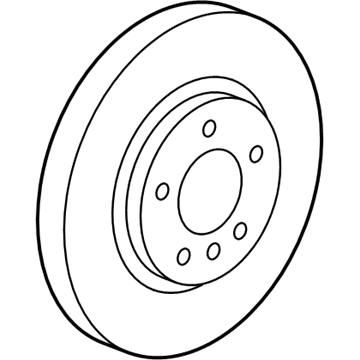

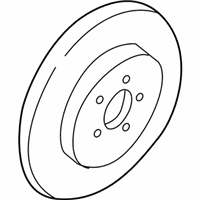

OEM Chevrolet Monte Carlo Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Brake Discs found

Chevrolet Monte Carlo Rotor, Front Part Number: 23127613

$167.82 MSRP: $325.72You Save: $157.90 (49%)Ships in 1-2 Business DaysChevrolet Monte Carlo Rotor Part Number: 18060228

$18.01 MSRP: $94.00You Save: $75.99 (81%)Ships in 1-2 Business DaysChevrolet Monte Carlo Rotor, Front Part Number: 19171429

$53.21 MSRP: $95.01You Save: $41.80 (44%)Ships in 1-3 Business DaysChevrolet Monte Carlo Rotor, Front Part Number: 19303832

$48.29 MSRP: $146.71You Save: $98.42 (68%)Chevrolet Monte Carlo Rotor Part Number: 19303830

$57.91 MSRP: $159.19You Save: $101.28 (64%)Ships in 1-2 Business Days

Chevrolet Monte Carlo Rotor, Front Part Number: 19202731

Chevrolet Monte Carlo Rotor, Front Part Number: 19245461

Chevrolet Monte Carlo Brake Drum, Front Part Number: 18060242

Chevrolet Monte Carlo Brake Disc

Want to cut long-term maintenance and repair costs? Choose OEM Brake Disc. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Monte Carlo parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Monte Carlo Brake Disc includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

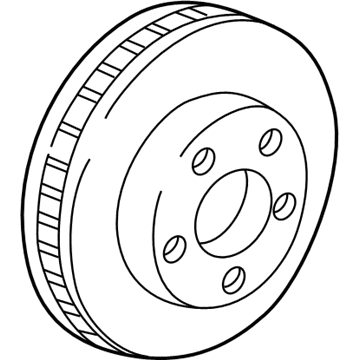

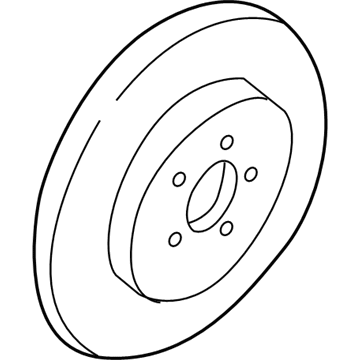

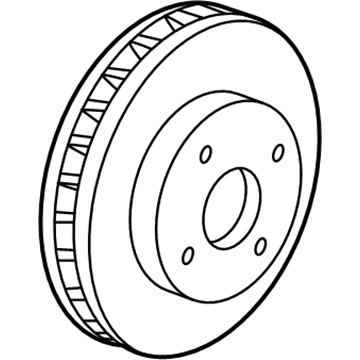

The brake disc in the Chevrolet Monte Carlo is part of the disc brake system which offers the requisite friction surface, on which the brake pads can act in order to slow down or stop the car. Sitting upright on the axle or hub, the rotor goes round with the wheel; in braking, hydraulic pressure squeezes the caliper and compresses the pads onto the rotor. The Brake Discs over the years come in different types, the solid type and the vented type among them. Some models utilise vented rotors, cast with cooling fins to improve cooling over that provided by solid rotors more commonly fitted to less sporting models. Virtually all rotors are constructed from cast iron with the possibility of utilizing composites for high performance. Instead, it requires periodic check-ups because irregularities such as scoring, warping, or more than permissible run-out adversely affect the braking capability, making it necessary to stick new rotors for the sake of safety and performance.

Chevrolet Monte Carlo Brake Disc Parts and Q&A

- Q: What are the essential steps to take before checking for assembled lateral runout (LRO) in brake discs on Chevrolet Monte Carlo?A:You must check brake disc thickness variation first because brake pulsation could result from exceeding the maximum buildup. When the assembled LRO exceeds permitted limits it leads to brake disc thickness changes which typically occur during 4,800 to 11,300 km (3,000 to 7,000 mi) of travel. To correct assembled LRO, consider the following methods based on the specific vehicle being repaired: the indexing method is effective for small LRO exceedances of 0.025-0.127 mm (0.001-0.005 in) and aims to match high spots to low spots between related components; the correction plate method involves adding a tapered plate between the brake disc and the hub/axle flange to correct LRO exceeding the specification by up to 0.23 mm (0.009 in); and the on-vehicle brake lathe method refines the brake disc while compensating for LRO to bring it within specifications. Other parts likely need adjustment when standard procedures fail to solve brake disc runout problems.

- Q: How to replace the front brake disc on Chevrolet Monte Carlo?A:Vehicle service begins with raising and supporting it to proceed with tire and wheel removal. A c-clamp will compress the Piston into the caliper bore when used to allow caliper movement from the rotor and after that remove the clamp. Ice the brake caliper with mechanic's wire or an equivalent system to defend the hydraulic flexible brake hose from damage. Proceed by removing the bolts that secure the caliper bracket while leaving the brake flexible hose bolt in place. Pull off the brake caliper with mounting bracket assembly from the suspension knuckle but keep the hydraulic brake flexible hose without any tension. The brake rotor must keep its matching position relative to wheel studs before getting removed. The new rotor installation requires cleaning all rust and contaminants from hub/axle flanges using wheel hub resurfacing kit (J 42450-A) and brake rotor contaminants require rotor resurfacing kit (J41013). The mating surfaces must be without debris so the brake rotor can be properly installed to the hub/axle flange using alignment marks. The assembled lateral runout (LRO) of the brake rotor requires measurement to verify optimal performance so any measurements beyond specifications should be corrected. Finish by installing the brake caliper along with the caliper bracket to the suspension knuckle and returning the tire wheel assembly back to its position then lowering the vehicle before conducting pad and rotor burnishing if a new rotor or resurfacing process was implemented.