ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Prizm Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Flywheels found

Chevrolet Prizm Pressure Plate Part Number: 88972974

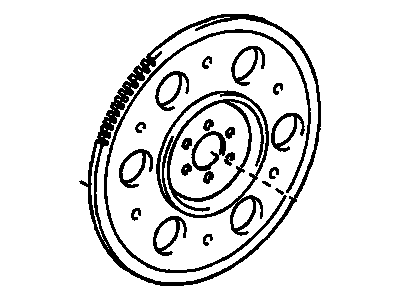

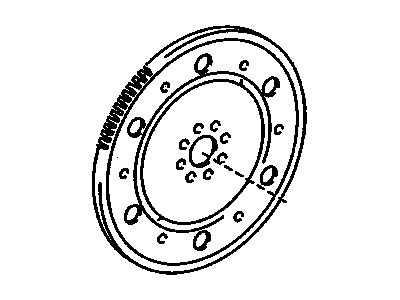

Chevrolet Prizm Flywheel Part Number: 88975895

Chevrolet Prizm Flywheel

Want to cut long-term maintenance and repair costs? Choose OEM Flywheel. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Prizm parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Prizm Flywheel includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Prizm Flywheel Parts Questions & Experts Answers

- Q: How to Service and Repair a Flywheel on Chevrolet Prizm?A:Disconnection of the negative Battery Cable should be the first step to service and repair the Flywheel. The service demands removal of transaxle assembly in both manual and automatic transmission setups. Operators of automobiles with manual transmissions should detach the clutch and Pressure Plate. Begin by taking off the Flywheel from the Crankshaft while removing its eight retaining bolts. Apply suitable solvent to eliminate surface grease and dirt from the Crankshaft flange. The installation process starts by mounting the Flywheel onto the Crankshaft but you must avoid applying too much sealant to the Flywheel retaining bolt threads. Use gm p/n 12345493 or its equivalent product to treat the Flywheel retaining bolts' threads. Install the automatic transmission Flywheel retaining bolts (1-8) according to this sequence while tightening them to 83 nm (61 ft. Lbs.). To install the Flywheel retaining bolts on manual transmission vehicles follow a sequence of tightening the first set to 49 nm (36 ft. Lbs.) and then complete the installation by using j 36660-a torque angle meter (J 36660-A) to reach an additional 90 degrees of torque. Reinstall the manual transmission clutch together with the Pressure Plate after installation. To finish the repair you need to reinstall the transaxle assembly according to requirements before reconnecting the negative Battery Cable while torquing the Battery Cable bolt to 15 nm (11 ft. Lbs.).