ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Silverado 1500 Drive Shaft

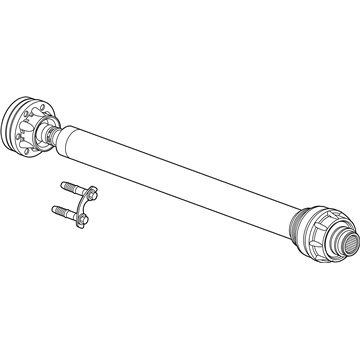

Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

79 Drive Shafts found

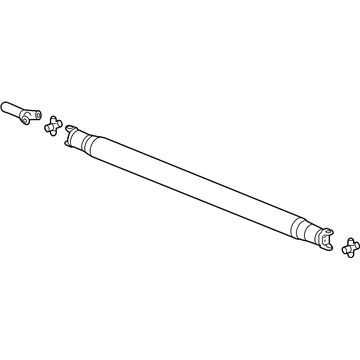

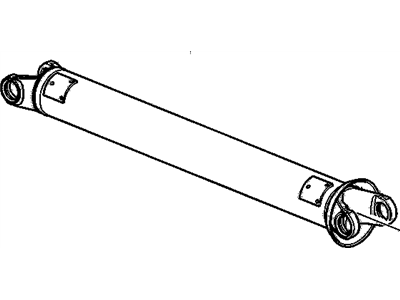

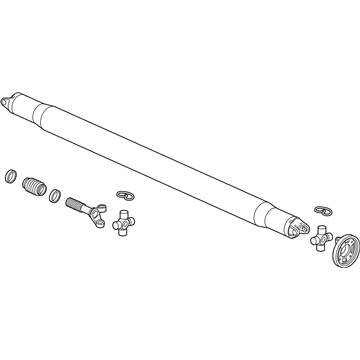

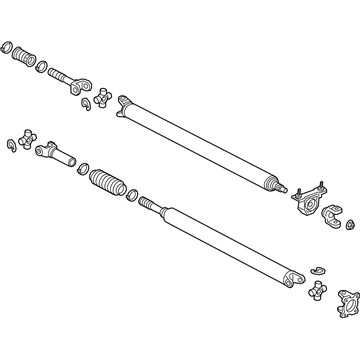

Chevrolet Silverado 1500 Drive Shaft Assembly Part Number: 23242262

$503.86 MSRP: $1248.64You Save: $744.78 (60%)Ships in 1-3 Business Days

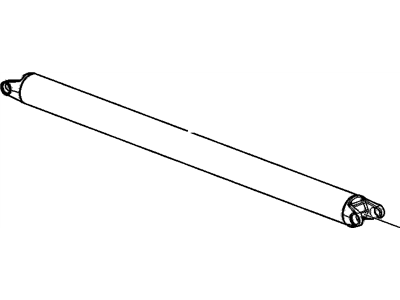

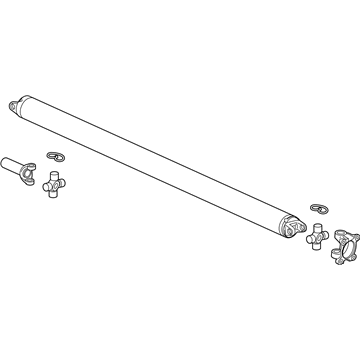

Chevrolet Silverado 1500 Drive Shaft Part Number: 23251126

$1286.54 MSRP: $3218.01You Save: $1931.47 (61%)Ships in 1-3 Business Days

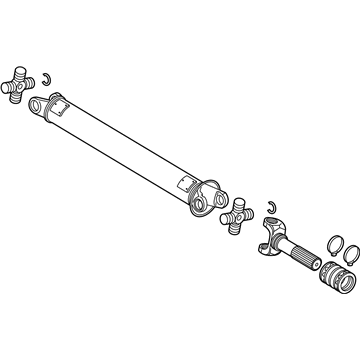

Chevrolet Silverado 1500 Drive Shaft Part Number: 23508419

$1301.53 MSRP: $2878.34You Save: $1576.81 (55%)Ships in 1-3 Business Days

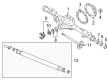

Chevrolet Silverado 1500 Drive Shaft, Front Part Number: 22760960

$398.11 MSRP: $696.20You Save: $298.09 (43%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Drive Shaft Part Number: 23242263

$481.37 MSRP: $1239.67You Save: $758.30 (62%)Ships in 1-2 Business DaysChevrolet Silverado 1500 Drive Shaft, Front Part Number: 84669663

$313.29 MSRP: $624.71You Save: $311.42 (50%)Ships in 1-2 Business DaysChevrolet Silverado 1500 Drive Shaft, Front Part Number: 22760959

$328.93 MSRP: $579.32You Save: $250.39 (44%)Ships in 1-2 Business DaysChevrolet Silverado 1500 Drive Shaft Part Number: 23508418

$1145.68 MSRP: $1946.60You Save: $800.92 (42%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Drive Shaft Part Number: 23370122

$329.19 MSRP: $517.86You Save: $188.67 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Drive Shaft Part Number: 84907480

$560.71 MSRP: $886.03You Save: $325.32 (37%)Chevrolet Silverado 1500 Drive Shaft, Front Part Number: 85519801

$246.79 MSRP: $388.23You Save: $141.44 (37%)Ships in 1-2 Business DaysChevrolet Silverado 1500 Drive Shaft Part Number: 23370108

$389.10 MSRP: $612.09You Save: $222.99 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Drive Shaft Part Number: 84907478

$570.32 MSRP: $901.40You Save: $331.08 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Drive Shaft Part Number: 23370107

$338.61 MSRP: $532.66You Save: $194.05 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Drive Shaft Part Number: 84997517

$588.62 MSRP: $1010.94You Save: $422.32 (42%)Chevrolet Silverado 1500 Drive Shaft Part Number: 23508420

$129.84 MSRP: $204.30You Save: $74.46 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Drive Shaft Part Number: 23370123

$301.04 MSRP: $473.56You Save: $172.52 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Drive Shaft Part Number: 84907491

$505.64 MSRP: $799.00You Save: $293.36 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Drive Shaft Part Number: 23370098

$544.18 MSRP: $859.91You Save: $315.73 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Drive Shaft Part Number: 23370095

$544.30 MSRP: $860.10You Save: $315.80 (37%)Ships in 1-3 Business Days

| Page 1 of 4 |Next >

1-20 of 79 Results

Chevrolet Silverado 1500 Drive Shaft

Want to cut long-term maintenance and repair costs? Choose OEM Drive Shaft. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Silverado 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Silverado 1500 Drive Shaft includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Silverado 1500 Drive Shaft Parts Questions & Experts Answers

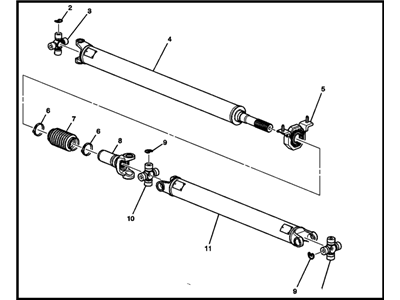

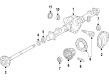

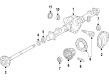

- Q: How to replace the front drive shaft on Chevrolet Silverado 1500?A:The process of front propeller shaft replacement begins by acquiring the clamp pliers - narrow jaw (J 43218) as one necessary tool. The reinstallation process requires accurate reference marking of all driveline components that relate to the propeller shaft and axles which includes propeller shafts and wheel drive shafts and pinion flanges as well as output shafts for proper reassembly alignment. You must elevate your vehicle and separate the Transfer Case clamp through natural tool opening of its exposed end with a flat-bladed tool. The technician should create reference points that show the alignment status between the propeller shaft and front axle pinion yoke. Protection of the injection joints requires not striking the yoke ears manually or inserting any tools between the yoke and Universal Joint. Detach all bolts and yoke retainers from the front axle pinion yoke and manage the bearing cap assemblies to prevent loss. The propeller shaft should be detached from the front axle pinion yoke before applying tape around each bearing cap to safeguard rollers from loss. Detach the propeller shaft by first removing its boot from the Transfer Case output shaft groove and moving the shaft forward to separate it. After securing each bearing cap with tape replace the boot. To proceed with the inspection remove any boot clamp from the propeller shaft boot along with the boot itself. Check the splines of the Transfer Case output shaft for appropriate lubricant before applying grease, gm p/n 12345879 (Canadian P/N 10953511), or equivalent lubricant which meets gm specification 9985830. After booting and clamping the propeller shaft boot you should slide the propeller shaft into the Transfer Case output shaft using the splines. The propeller shaft requires reinstallation to the front axle pinion yoke while you align reference marks established when removing it. Install the yoke retainers followed by bolts and tighten yoke retainer bolts to 25 n.m (18 lb ft). At last fit the boot onto the Transfer Case output shaft until the groove receives it and use clamp pliers - narrow jaw (J 43218) to crimp both clamps before lowering the vehicle.