ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Suburban 1500 Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Engine Mounts found

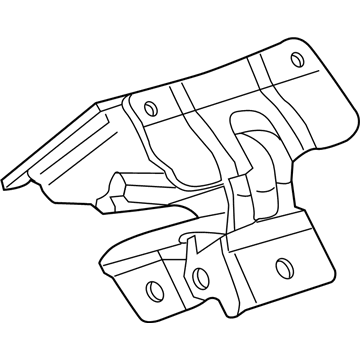

Chevrolet Suburban 1500 Motor Mount Part Number: 15226255

$125.59 MSRP: $215.69You Save: $90.10 (42%)

Chevrolet Suburban 1500 Motor Mount, Green Part Number: 25828247

$132.41 MSRP: $227.41You Save: $95.00 (42%)

Chevrolet Suburban 1500 Motor Mount Part Number: 15854941

$170.53 MSRP: $292.89You Save: $122.36 (42%)

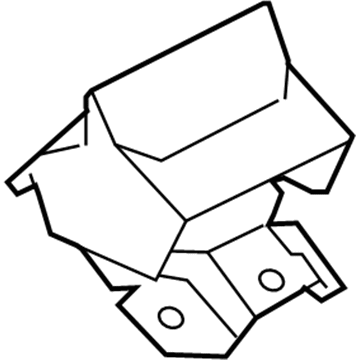

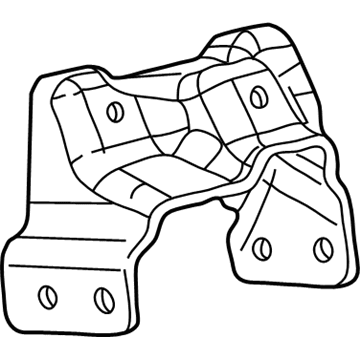

Chevrolet Suburban 1500 Mount Bracket, Passenger Side Part Number: 15113847

$47.39 MSRP: $80.69You Save: $33.30 (42%)Ships in 1-2 Business DaysChevrolet Suburban 1500 Mount Bracket, Driver Side Part Number: 15113849

$59.70 MSRP: $93.50You Save: $33.80 (37%)

Chevrolet Suburban 1500 Engine Mount

Want to cut long-term maintenance and repair costs? Choose OEM Engine Mount. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Suburban 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Suburban 1500 Engine Mount includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Suburban 1500 Engine Mount Parts Questions & Experts Answers

- Q: How to replace the engine mount on Chevrolet Suburban 1500?A:First inspect your mount for damage along with looseness because broken and deteriorated mounts will lead to misaligned drive train components that stress remaining mounts beyond normal limits when a mount fails. Start the procedure by lifting the vehicle and unbolting the upper mount from the lower Engine Mount using its three retaining bolts while simultaneously taking out the underbody shield. Engine support must be achieved through a screw jack that holds the engine rather than by using the Oil Pan or crankshaft balancer. Remove the bolts from the upper mount to the engine before taking out the upper mount and then remove the lower Engine Mount Bracket through bolts together with the bracket from the frame structure. Begin by attaching the lower Engine Mount to the frame before inserting through bolts then tighten them initially by fingers only. Plant the upper Engine Mount on the engine block followed by securing its bolts until they reach 50 nm torque (37 ft. Lbs.). Follow by vehicle lowering and proceed with connecting the upper and lower Engine Mount using their three bolts until you achieve 50 nm (37 ft. Lbs.) torque. The through bolts require installation when the vehicle reaches its maximum height and the torque should be set to 92 nm (68 ft. Lbs.). Following this step finish by replacing the underbody shield before lowering the vehicle.