ChevyParts

My Garage

My Account

Cart

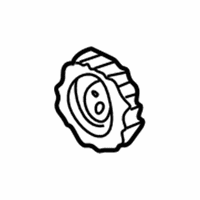

OEM Chevrolet Variable Timing Sprocket

Timing Gear Sprocket- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

78 Variable Timing Sprockets found

Chevrolet Camshaft Gear Part Number: 24505306

$55.09 MSRP: $86.30You Save: $31.21 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket, Camshaft; Variable Valve Timing Sprocket; Timing Gear; Cam Gear; Timing Gear Set; Sprocket, Engine Camshaft

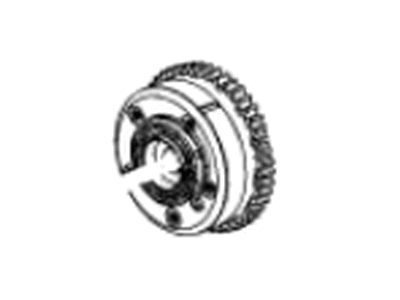

Chevrolet Camshaft Gear Part Number: 12552128

$111.44 MSRP: $223.75You Save: $112.31 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sprocket, Engine Camshaft; Variable Valve Timing Sprocket; Timing Gear; Cam Gear; Timing Gear Set

Chevrolet Camshaft Gear Part Number: 340235

$58.88 MSRP: $92.23You Save: $33.35 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket, Camshaft; Variable Valve Timing Sprocket; Timing Gear; Cam Gear; Timing Gear Set; Sprocket, Engine Camshaft; Gear, Engine Camshaft

Chevrolet Camshaft Gear Part Number: 12560176

$31.09 MSRP: $48.70You Save: $17.61 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket, Engine Camshaft; Variable Valve Timing Sprocket; Cam Gear

Chevrolet Camshaft Gear, Driver Side Part Number: 12597413

$84.46 MSRP: $132.30You Save: $47.84 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket, Camshaft; Variable Valve Timing Sprocket; Cam Gear; Intermediate Gear; Sprocket, Engine Camshaft

- Position: Driver Side

Chevrolet Camshaft Gear Part Number: 12589766

$40.68 MSRP: $67.01You Save: $26.33 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket, Engine Camshaft; Variable Valve Timing Sprocket; Cam Gear

Chevrolet Camshaft Gear Part Number: 24505393

$51.87 MSRP: $81.23You Save: $29.36 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket, Engine Camshaft; Variable Valve Timing Sprocket; Cam Gear

Chevrolet Camshaft Gear Part Number: 12551401

$76.14 MSRP: $119.27You Save: $43.13 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sprocket, Engine Camshaft; Variable Valve Timing Sprocket; Cam Gear

Chevrolet Crankshaft Gear Part Number: 12671641

$71.99 MSRP: $112.77You Save: $40.78 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sprocket, Engine Crankshaft/Timing

- Replaced by: 12725693

- Replaces: 12687452

Chevrolet Camshaft Gear Part Number: 10128349

$25.20 MSRP: $39.48You Save: $14.28 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket, Engine Camshaft; Variable Valve Timing Sprocket; Cam Gear

Chevrolet Actuator Part Number: 55570268

$111.59 MSRP: $174.79You Save: $63.20 (37%)Product Specifications- Other Name: Sprocket, Engine Camshaft

Chevrolet Camshaft Gear Part Number: 12691939

$171.73 MSRP: $270.23You Save: $98.50 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gear Assembly-Camshaft; Variable Valve Timing Sprocket; Timing Gear; Cam Gear; Timing Gear Set

- Replaced by: 12721405

Chevrolet Camshaft Gear Part Number: 19316192

$264.02 MSRP: $415.42You Save: $151.40 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket, Engine Camshaft; Variable Valve Timing Sprocket; Cam Gear

Chevrolet Camshaft Gear Part Number: 12623754

$28.32 MSRP: $44.38You Save: $16.06 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket, Engine Camshaft; Variable Valve Timing Sprocket; Cam Gear

Chevrolet Camshaft Gear Part Number: 24506089

$44.91 MSRP: $70.35You Save: $25.44 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket, Engine Camshaft; Variable Valve Timing Sprocket; Timing Gear; Cam Gear; Timing Gear Set

Chevrolet Actuator Part Number: 25191779

$104.92 MSRP: $164.35You Save: $59.43 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket, Engine Camshaft

- Replaces: 25187905

Chevrolet Camshaft Gear Part Number: 55489218

$6.10 MSRP: $9.56You Save: $3.46 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sprocket, Engine Camshaft; Variable Valve Timing Sprocket; Cam Gear

Chevrolet Idler Gear Part Number: 55500069

$116.04 MSRP: $182.58You Save: $66.54 (37%)Product Specifications- Other Name: Sprocket Assembly-Timing Chain Idler; Sprocket, Engine Timing

- Replaces: 55490405

Chevrolet Actuator Part Number: 55494199

$75.90 MSRP: $118.89You Save: $42.99 (37%)Product Specifications- Other Name: Sprocket Assembly-Camshaft (W/ Camshaft Position Actuator); Sprocket, Engine Camshaft

Chevrolet Camshaft Gear Part Number: 55573054

$44.81 MSRP: $70.20You Save: $25.39 (37%)Product Specifications- Other Name: Sprocket, Engine Camshaft; Variable Valve Timing Sprocket; Cam Gear

| Page 1 of 4 |Next >

1-20 of 78 Results

Chevrolet Variable Timing Sprocket

Want to cut long-term maintenance and repair costs? Choose OEM Variable Timing Sprocket. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Variable Timing Sprocket includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Variable Timing Sprocket Parts Questions & Experts Answers

- Q: How to replace the timing chain and variable timing sprocket on the crankshaft on Chevrolet Tracker?A:To replace the timing chain and sprockets on the Crankshaft, one is required to remove the negative Battery Cable and the sparkplugs to allow one to aid in the function of clocking the Crankshaft. Remove the timing chain housing taking note of the correct timing of its marks before disassembling it. The camshafts can be rotated 15 degrees off the notches on the Cylinder Head (15 degrees), but in case it is needed, the Crankshaft can be rotated 90 degrees off the mark on the block of the engine (15 degrees). Rotate the Crankshaft and make it align with the number one cylinder at top dead centre, key on Crankshaft face with mark from engine block, idler sprocket with arrow pointing upward, camshaft sprockets should be guide pins aligning to the notches on the Cylinder Head. Relieve tension on the Camshaft timing by turning the intake Camshaft a little counter clock wise, remove the nut and 2 bolts (1,2) do not turn the Camshaft or Crankshaft after and remove the tensioner. Take out the Camshaft Timing Chain Tensioner and gasket, use wrench to get the cam shaft, take out the Camshaft sprockets and chain before removing the Camshaft sprockets and chain bolts. Inspect the Camshaft timing chain upper guide, tensioner, tensioner gasket, sprockets, and chain for wear and damage, replacing any parts that have worn out. Secondly, unscrew the 2 bolts and Crankshaft Timing Chain Tensioner, the bolt and Crankshaft timing chain adjustable guide, and the 2 bolts and Crankshaft timing chain fixed guide. Take out the idler sprocket and Crankshaft timing chain, followed by its Crankshaft timing sprocket, the latch in the timing chain guides, idler sprocket, crankshaft timing sprocket, and Crankshaft timing chain for wear and damage while replacing worn parts ensuring the latch and teeth of your Crankshaft Timing Chain Tensioner work correctly before replacing them. For installation, make sure the timing mark of engine block corresponds to the Crankshaft sprocket keyway, then install Crankshaft sprocket and apply engine oil on idler sprocket bushing. Swing the timing chain across to the idler sprocket, locate the mark on the sprocket and the dark blue link , then push the link onto the mark. Swing the timing chain across to the Crankshaft sprocket locating the mark on the Crankshaft sprocket and the yellow link then push the link onto the mark. Install the idler sprocket and the timing chain fixed guide with the bolts tightened to 9 nm (62 inch lbs.) and the timing chain adjustable guide with bolt tightened to 25 nm (19 ft. Lbs.). Push back the latch, compress the plunger and retain the plunger with a retainer before you will install the Timing Chain Tensioner using bolts with a torque setting of 11n.m (97 inch lbs.). Remove the retainer and ensure the Crankshaft keyway aligns with the mark on the engine block , the yellow link of the Crankshaft timing chain aligns with the Crankshaft timing mark , and the dark blue link aligns with the mark on the idler sprocket. Make sure the guide pins of the camshafts to align with the notches of the Cylinder Head, and the idler sprocket arrow should be pointing upwards. Compare the alignment of the yellow link of the Camshaft timing chain with the arrow on the idler sprocket and the dark blue link with the arrows 2,3 on the Camshaft sprockets before installing the Camshaft timing sprockets and chain before the Camshaft sprocket bolts are tightened to 80 nm (58 ft. Lbs.). Push in the Camshaft on the plunger into the body and secure it with retainer to keep still fit Camshaft Timing Chain Tensioner by applying bolts that are screwed to the tensioner 11 nm (97 inch lbs.) and nut 45 nm (33 ft. Lbs.). Take off the retainer, turn the Crankshaft 2 revolutions for realigning the keyway, the Crankshaft with the timing mark, engine block , and that guide pins on camshafts are in line with notches on Cylinder Head . Apply engine oil to the timing chains, tensioner, guides, and sprockets, install the spark plugs, set tightness to 25 nm and 18 ft. Lbswu of torque, then install the timing chain housing, and reconnect the negative Battery Cable.

- Q: How to replace the timing chain, variable timing sprocket, or timing chain tensioner on Chevrolet Malibu?A:Standard procedure to replace a timing chain and its associated sprockets and tensioner starts with removing the engine front cover. Position the #1 Piston at top dead center (#4 firing position) and align the mark on the camshaft sprocket with the timing mark on the bottom of the timing chain dampener . Start by removing the camshaft sprocket bolt then the camshaft sprocket followed by removing the timing chain and timing chain dampener. A gentle blow with a plastic mallet on the sprocket's lower edge will help loosen it if removal proves difficult. Use crankshaft gear puller (J5825-A) to extract crankshaft sprocket. To install the crankshaft sprocket apply prelude gm p/n 1052365 or equivalent to the crankshaft sprocket thrust surface then use the crankshaft sprocket installer (J38612) as directed. Fit the timing chain dampener followed by tightening its bolts to 21 nm (15 ft. Lbs.). Place the crankshaft timing mark opposite the timing mark appearance on the bottom surface of the timing chain dampener . After holding the camshaft sprocket in place with the timing chain below, mount the timing chain on the crankshaft gear. Place the timing mark from the camshaft gear so it matches the timing mark on top of the timing chain dampener while also making sure the camshaft dowel slides into its dedicated hole in the camshaft sprocket. Use the fitting bolt to place the camshaft sprocket in position on the camshaft before applying engine oil to both sprockets followed by a 140 nm (103 ft. Lbs.) bolt torque. As the final step install the engine front cover.

- Q: How to remove the Timing Chain and Variable Timing Sprocket on Chevrolet Prizm?A:The first step involves removing the Timing Chain dampener bolts and Timing Chain dampener followed by the Timing Chain shoe bolts and finally the Timing Chain shoe. Crankshaft sprocket and Timing Chain need simultaneous removal during the procedure.

Related Chevrolet Parts

Browse Chevrolet Variable Timing Sprocket by Models

Nova S10 Colorado C10 Tahoe Cruze Malibu Camaro Equinox Impala SS SSR Avalanche Silverado 1500 Silverado 2500 HD Caprice Classic Cobalt Suburban Traverse Blazer HHR Sonic Tracker Volt El Camino K10 Spark Trax Trailblazer Astro Cavalier Corvette C20 Aveo Beretta C1500 C2500 C30 C3500 Celebrity Chevette City Express Corsica Express 1500 Express 2500 Express 3500 G10 G20 G30 K1500 K20 K2500 K30 K3500 K5 Blazer Lumina Metro Monte Carlo Prizm S10 Blazer Sprint Uplander Venture Lumina APV Silverado 3500 Suburban 1500 Trailblazer EXT Avalanche 2500 Aveo5 C10 Suburban C1500 Suburban C20 Suburban C2500 Suburban Captiva Sport Cruze Limited Impala Limited K10 Suburban K1500 Suburban K20 Suburban K2500 Suburban R10 R10 Suburban R1500 Suburban R20 R20 Suburban R2500 R2500 Suburban R30 R3500 Silverado 2500 HD Classic Silverado 3500 Classic Silverado 3500 HD Suburban 2500 V10 V10 Suburban V1500 Suburban V20 V20 Suburban V2500 Suburban V30 V3500