ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Harmonic Balancer

Engine Harmonic Balancer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

148 Harmonic Balancers found

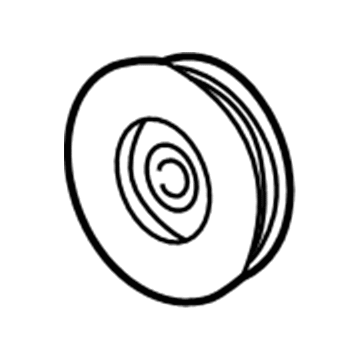

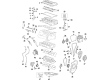

Chevrolet Vibration Damper Part Number: 19260268

$303.76 MSRP: $517.14You Save: $213.38 (42%)Product Specifications- Other Name: Damper, Engine Crankshaft And Camshaft Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

- Replaces: 10216338, 88960603

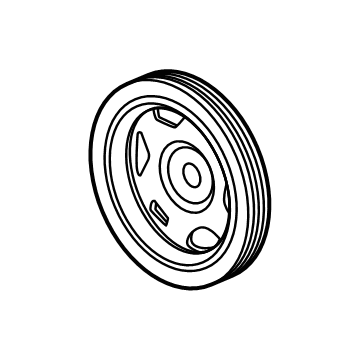

Chevrolet Crankshaft Pulley Part Number: 12583151

$106.56 MSRP: $166.91You Save: $60.35 (37%)Product Specifications- Other Name: Damper, Engine Crankshaft And Camshaft Balancer; Harmonic Balancer Puller; Harmonic Balancer; Vibration Damper; Crankshaft Balance Pulley; Engine Crankshaft and Camshaft Balancer.

Chevrolet Crank Pulley Part Number: 12674581

$600.58 MSRP: $1022.46You Save: $421.88 (42%)Product Specifications- Other Name: Pulley; Vibration Damper; Balancer, Engine Crankshaft And Camshaft Balancer

- Replaces: 12603916

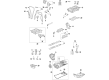

Chevrolet Crankshaft Balance Part Number: 12618249

$144.70 MSRP: $271.74You Save: $127.04 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley-Water Pump; Serpentine Belt Drive Kit; Water Pump Pulley; Pulley

- Replaced by: 19367394

Chevrolet Vibration Damper Part Number: 12571619

$113.11 MSRP: $186.33You Save: $73.22 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley; Harmonic Balancer; Balancer

- Replaced by: 12578069

Chevrolet Crankshaft Pulley Part Number: 12695128

$57.71 MSRP: $95.05You Save: $37.34 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley; Harmonic Balancer Puller; Harmonic Balancer; Vibration Damper; Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

Chevrolet Vibration Damper Part Number: 12707253

$58.18 MSRP: $91.13You Save: $32.95 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pulley; Harmonic Balancer; Balancer; Balancer, Engine Crankshaft

Chevrolet Crankshaft Pulley Part Number: 19418897

$242.14 MSRP: $415.85You Save: $173.71 (42%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pulley, Engine Crankshaft And Camshaft Balancer; Pulley

- Replaces: 10055879, 19367391

Chevrolet Vibration Damper Part Number: 12688494

$104.93 MSRP: $164.34You Save: $59.41 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Pulley; Harmonic Balancer; Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

Chevrolet Pulley Part Number: 12730508

$231.54 MSRP: $364.23You Save: $132.69 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

Chevrolet Vibration Damper Part Number: 12687726

$186.90 MSRP: $294.07You Save: $107.17 (37%)Product Specifications- Other Name: Pulley; Harmonic Balancer; Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

- Replaces: 12662040, 12668033

Chevrolet Crankshaft Pulley Part Number: 55571401

$54.17 MSRP: $84.87You Save: $30.70 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley; Harmonic Balancer Puller; Harmonic Balancer; Vibration Damper; Balancer, Engine Crankshaft And Camshaft Balancer

- Replaced by: 55574735

Chevrolet Vibration Damper Part Number: 19417972

$409.58 MSRP: $650.30You Save: $240.72 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Shaft Assembly, Balancer (Remanufacture); Harmonic Balancer; Balance Shaft; Balancer Shaft Kit; Engine Crankshaft and Camshaft Balancer.

- Replaces: 10224538

Chevrolet Vibration Damper Part Number: 55487414

$21.98 MSRP: $34.89You Save: $12.91 (37%)Product Specifications- Other Name: Pulley; Harmonic Balancer; Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

Chevrolet Vibration Damper Part Number: 12668034

$213.78 MSRP: $352.15You Save: $138.37 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley; Harmonic Balancer; Balancer

- Replaced by: 12687727

Chevrolet Crank Pulley Part Number: 12615141

$76.34 MSRP: $124.96You Save: $48.62 (39%)Product Specifications- Other Name: Balancer, Crankshaft; Harmonic Balancer; Vibration Damper; Balancer; Balancer, Engine Crankshaft And Camshaft Balancer

- Replaces: 12702117

Chevrolet Vibration Damper Part Number: 12552283

$221.35 MSRP: $376.87You Save: $155.52 (42%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Balancer, Engine Crankshaft; Balancer, Engine Crankshaft And Camshaft Balancer

Chevrolet Vibration Damper Part Number: 10243272

$207.93 MSRP: $357.10You Save: $149.17 (42%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pulley; Balancer, Engine Crankshaft And Camshaft Balancer

Chevrolet Crankshaft Pulley Part Number: 19316093

$198.89 MSRP: $312.95You Save: $114.06 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Balancer, Crankshaft; Harmonic Balancer Puller; Pulley; Balancer, Engine Crankshaft And Camshaft Balancer

Chevrolet Vibration Damper Part Number: 12723412

$105.60 MSRP: $165.43You Save: $59.83 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Balancer, Crankshaft; Balancer, Engine Crankshaft And Camshaft Balancer; Balancer, Engine Crankshaft

- Replaces: 12674749, 12714005, 12682185, 12675030, 12702576

| Page 1 of 8 |Next >

1-20 of 148 Results

Chevrolet Harmonic Balancer

Want to cut long-term maintenance and repair costs? Choose OEM Harmonic Balancer. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Harmonic Balancer includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Harmonic Balancer Parts Questions & Experts Answers

- Q: How to Properly Service the Harmonic Balancer on a Chevrolet Colorado?A:The crankshaft balancer replacement process starts by taking out both the Radiator along with the Drive Belt before lifting the vehicle for support. The crankshaft balancer touch point plug can be removed now because the device lacks a necessary key slot for proper torque control when it turns. Use the en 46547 (Flywheel Holding Tool) to place into the flywheel teeth while lowering the vehicle before discarding the crankshaft balancer bolt. The crankshaft balancer removal process requires j 41816-2 (Crankshaft End Protector) together with j 41816-a (Crankshaft Balancer Remover) to handle the balancer properly. Avoid pulling on the edge of the outer section. When installing the new crankshaft balancer employ the en-48034 (Harmonic Balancer Installer) and later remove it from the installation site. Install the crankshaft balancer washer together with a fresh bolt before torquing them to 150 nm (111 lb ft) while turning the j 45059 (Angle Meter) an extra 180 degrees. After vehicle support the technician will remove the en 46547 (Flywheel Holding Tool) from the flywheel teeth before installing the service slot plug and Drive Belt and Radiator.

- Q: How to replace the harmonic balancer on Chevrolet Malibu?A:Start the crankshaft balancer replacement by taking off the engine Drive Belt. The Harmonic Balancer holder (J 38122-A) immobilizes the crankshaft during crankshaft balancer bolt loosening. After loosening, discard the bolt. The procedure moves to crankshaft balancer removal. Install the new crankshaft balancer onto the crankshaft before tightening an all-new crankshaft balancer bolt by following the fastener notice in service precautions. Present the crankshaft from rotating by using the Harmonic Balancer holder (J 38122-A) when you torque the new crankshaft balancer bolt to 100 nm (74 ft. Lbs.) followed by a 75-degree extension. The last step involves putting back the engine Drive Belt.

- Q: How to replace the harmonic balancer on Chevrolet Tahoe?A:The a/c Drive Belt and cooling fan and shroud need removal before starting the Crankshaft balancer replacement process but the engine Flywheel must have j 42386-a (Flywheel Holding Tool) teeth overlapping its surface. The installation of the j 42386-a demands two bolts with m10-1.5 x 120 mm and m10-1.5 x 45 mm specifications which must reach a torque of 50 nm (37 lb ft). Proceed by discarding the Crankshaft balancer bolt labeled 139 because it will be used again for reinstallation. The procedure starts by connecting the j 41816-a (Crankshaft Balancer Remover) and j 41816-2 (Crankshaft End Protector) on the Crankshaft balancer before removing it. During installation users must begin by placing the Crankshaft balancer (138) onto the Crankshaft while utilising the j 41665 (Crankshaft Balancer and Sprocket Installer with its threaded rod drawn from the J 41478 (Crankshaft Front Oil Seal Installer). First combine the threaded rod and nut with washer and installation tool before putting the smaller end section into the front of the balancer assembly. Use a wrench to hold the threaded rod hex end before tightening the installation tool nut clockwise until the balancer starts onto the Crankshaft. After directing the installation tool with its larger end toward the balancer front, continue tightening until full installation. The used Crankshaft balancer bolt (139) receives installation before it is torqued to 330 nm (240 lb ft) then removed. When the Crankshaft nose reaches 2.4-4.48 mm (0.094-0.176 in) below balancer bore level the installation should be redone. The installation process of new Crankshaft balancer bolt (139) should start with a 50 nm (37 lb ft) torque before finishing with a 140-degree final tightening using the j 45059 (Angle Meter). The repair procedure ends with the removal of j 42386-a and bolts then reinstalls the cooling fan and shroud with the a/c Drive Belt followed by performing Crankshaft position (CKP) system variation learn procedure.

Related Chevrolet Parts

Browse Chevrolet Harmonic Balancer by Models

S10 Colorado C10 Tahoe Cruze Malibu Camaro Equinox Impala SS SSR Avalanche Silverado 1500 Silverado 2500 HD Caprice Classic Cobalt Suburban Traverse Blazer HHR Sonic Tracker Volt El Camino K10 Spark Trax Trailblazer Astro Cavalier Corvette C20 Aveo Beretta C1500 C2500 C30 C3500 Celebrity City Express Corsica Express 1500 Express 2500 Express 3500 G10 G20 G30 K1500 K20 K2500 K30 K3500 K5 Blazer Lumina Metro Monte Carlo P30 S10 Blazer Silverado 2500 Uplander Venture Lumina APV Silverado 3500 Suburban 1500 Trailblazer EXT Avalanche 1500 Avalanche 2500 Aveo5 C10 Suburban C1500 Suburban C20 Suburban C2500 Suburban Captiva Sport Citation II Cruze Limited Impala Limited K10 Suburban K1500 Suburban K20 Suburban K2500 Suburban Malibu Limited P20 R10 R10 Suburban R1500 Suburban R20 R20 Suburban R2500 R2500 Suburban R30 R3500 Silverado 1500 Classic Silverado 1500 HD Silverado 1500 HD Classic Silverado 1500 LD Silverado 1500 LTD Silverado 2500 HD Classic Silverado 3500 Classic Silverado 3500 HD Suburban 2500 Suburban 3500 HD V10 V10 Suburban V1500 Suburban V20 V20 Suburban V2500 Suburban V30 V3500