ChevyParts

My Garage

My Account

Cart

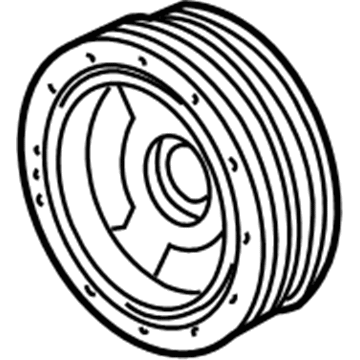

OEM Chevrolet SSR Harmonic Balancer

Engine Harmonic Balancer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Harmonic Balancer found

Chevrolet SSR Vibration Damper Part Number: 12634105

Chevrolet SSR Harmonic Balancer

Want to cut long-term maintenance and repair costs? Choose OEM Harmonic Balancer. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet SSR parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet SSR Harmonic Balancer includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

The Chevrolet SSR Harmonic Balancer is a part that does assist in increasing the dependability and efficiency of the Chevrolet SSR, a fantastic retractable hardtop convertible pick-up truck manufactured from 2003 to 2006. This Harmonic Balancer has the function of balancing the engine and cushioning vibrations produced by the combustion process, and, therefore provides a more comfortable ride as well as increasing the overall efficiency of the engine. Among the Chevrolet SSR models, the 5.3L Vortec 5300 V8 and the 6.0L LS2 V8 engines prove to be very responsive because of this component which is produced to endure general and high performance operations. The viscous fluid and multi-piece aspects are tunable and can be rebuilt, catering to the modifications that increases horsepower and RPM concerning the Chevrolet SSR Harmonic Balancer. Such responsive capacity also contributes to the vehicle safety besides helping to counter any undue vibrations that may occur. Furthermore, it is worth adding that the additional features may encompass 360-degree timing marks used in tuning the Chevrolet SSR Harmonic Balancer's engines, which makes it unique in the market. Being an auto part brand widely acknowledged for its dependability and power, the Chevrolet SSR Harmonic Balancer is necessary to preserve the effectiveness and security of the Chevrolet SSR thus allowing the vehicle's owners to savor the character of this specific model while still receiving the optimal to their car.

Chevrolet SSR Harmonic Balancer Parts and Q&A

- Q: How to replace the harmonic balancer on Chevrolet SSR?A:Start the replacement by obtaining crankshaft balancer and sprocket installer (J 41665), crankshaft balancer remover (J 41816), crankshaft end protector (J 41816-2), Flywheel holding tool (J 42386-A), and torque angle meter (J 45059). Crank the sequence of component removal starts with removing the accessory Drive Belt and then proceeding to take off the air conditioning Drive Belt if present followed by cooling fan and Starter motor. .alignment of the engine Flywheel teeth must be achieved by Flywheel holding tool (J 42386-A) teeth. Position the tool of Flywheel holding tool (J 42386-A) using one m10-1.5 x 120 mm and one m10-1.5 x 45 mm bolt; tighten down both bolts to 50 nm (37 ft.lbs.). You should keep the crankshaft balancer bolt for reuse in the future installation. Use the crankshaft balancer remover (J 41816) while employing the crankshaft end protector (J 41816-2) to extract the crankshaft balancer before cleaning and inspection can occur. You should reinstall the Flywheel holding tool (J 42386-A) for installation purposes. The crankshaft balancer and sprocket installer (J 41665) enables crankshaft balancer installation according to the directed tightening process which begins with applying the existing balancer bolt to achieve 330 nm (240 ft. Lbs.) before bolt removal. Measure the correct positioning of the installed balancer before re-running the installation if needed. The crankshaft balancer bolt installation requires initial torque to 50 nm (37 ft. Lbs.) before adjusting its angle to 140 degrees using torque angle meter (J 45059). To complete the final stage of work replace the Flywheel holding tool (J 42386-A) with Starter motor and cooling fan and accessory Drive Belt and a/c Drive Belt.