ChevyParts

My Garage

My Account

Cart

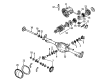

OEM GMC Envoy Pinion Bearing

Transmission Pinion Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Pinion Bearings found

GMC Envoy Pinion Bearings Part Number: 9439879

$35.47 MSRP: $105.01You Save: $69.54 (67%)

GMC Envoy Pinion Bearings Part Number: 9417784

$24.86 MSRP: $68.16You Save: $43.30 (64%)Ships in 1-2 Business Days

GMC Envoy Pinion Bearings Part Number: 9413427

$56.84 MSRP: $109.76You Save: $52.92 (49%)Ships in 1-2 Business Days

GMC Envoy Pinion Bearings, Inner Part Number: 457108

$56.11 MSRP: $154.36You Save: $98.25 (64%)Ships in 1-2 Business Days

GMC Envoy Side Bearings, Front Part Number: 26046759

$36.01 MSRP: $106.64You Save: $70.63 (67%)Ships in 1-2 Business Days

GMC Envoy Side Bearings Part Number: 25824250

$73.65 MSRP: $142.94You Save: $69.29 (49%)Ships in 1-2 Business Days

GMC Envoy Pinion Bearings Part Number: 23243839

$72.64 MSRP: $142.22You Save: $69.58 (49%)Ships in 1-2 Business Days

GMC Envoy Side Bearings Part Number: 11505123

$57.30 MSRP: $169.58You Save: $112.28 (67%)Ships in 1-2 Business Days

GMC Envoy Pinion Bearing

Want to cut long-term maintenance and repair costs? Choose OEM Pinion Bearing. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Envoy parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Envoy Pinion Bearing includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

The GMC Envoy Pinion Bearing stands as a fundamental element which increases reliability performance levels in all GMC Envoy vehicles. As an essential component this bearing enables the differential pinion gear to rotate smoothly in order to deliver proper power transmissions from driveshafts to wheels. During the production period from 1998 to 2009 GM built various Envoy models which would not function properly without the durable Pinion Bearing responsible for differential system efficiency. The Pinion Bearing requires regular maintenance because its malfunction causes audible signs that may harm adjacent parts thus necessitating periodic lubrication or replacement. The GMC Envoy benefits from a higher safety level and improved driving experience because its dependable Pinion Bearing component operates efficiently. This particular pinion bearing design accommodates all GMC Envoy trims from the SLT and model XL series up to the luxury sedan automobile Denali. Its versatile characteristics together with strong manufacturing create the GMC car Pinion Bearing as an elite product for the automotive marketplace. Through its ability to optimize the automaker model performance duration and safety features the Pinion Bearing persuades SUV enthusiasts to choose the model as their reliable vehicle.

GMC Envoy Pinion Bearing Parts Questions & Experts Answers

- Q: How to replace the drive pinion bearings in the rear drive axle on GMC Envoy?A:The process of swapping drive pinion bearings in rear drive axles starts with vehicle elevation and Differential and drive pinion removal from the axle. The split-plate bearing puller (J 22912-01) should be used to push off the bearing which sits on the pinion before you can remove the shim. When extracting bearings from the axle housing work evenly with a hammer against a brass drift to remove the outer cup followed by the inner cup extraction. The installation of the outer Pinion Bearing cup requires an outer bearing race installer (J 7817) and universal driver handle (J 8092) while the installation of the inner Pinion Bearing cup needs a rear Pinion Bearing race installer (J 8608) with the universal driver handle (J 8092). Insert the selective shim of the chosen thickness between the inner Pinion Bearing and gear shoulder. Execute the inner Pinion Bearing installation with pinion cone and side bearing installer j 24433 while pushing it down until the cone completely seats onto the pinion shim. The installation process requires a new collapsible spacer with proper axle lubricant application to the pinion bearings. Place the axle housing pinion next to the outside bearing before adding both components. The pinion oil seal installer (J 33782) must be used for new pinion oil seal installation before applying gm p/n 12346004 (Canadian P/N 10953480) sealant to the pinion yoke splines and placing the yoke in position. Finally, match attaining alignment along the original marks. Drive the pinion yoke onto the pinion shaft using a soft-faced hammer until it shows a few threads. Subsequently add the washer and brand-new pinion nut. Using the holding tool (J 8614-01) on the pinion yoke secure it while tightening the pinion nut until the end play reaches its minimal point. A mechanic should use an inch-pound torque wrench to measure pinion rotating torque at 1.0 to 2.8 nm (10 to 25 inch lbs.) for used bearings or 1.7 to 3.4 nm (15 to 30 inch lbs.) for new bearings. Tighten the pinion nut by small amounts until its rotating torque matches the specified range. Use the torque meter to check the specified value before rotating the pinion at least three times to check bearing seating. Make additional adjustments if required. The vehicle requires reinstallation of its Differential before lubricating the axle with proper fluid then proceeding to lower the vehicle.