ChevyParts

My Garage

My Account

Cart

OEM GMC Jimmy Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Universal Joints found

GMC Jimmy Universal Joints Part Number: 23104840

$36.45 MSRP: $88.98You Save: $52.53 (60%)GMC Jimmy Universal Joints Part Number: 7849090

GMC Jimmy Universal Joint

Want to cut long-term maintenance and repair costs? Choose OEM Universal Joint. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Jimmy parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Jimmy Universal Joint includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

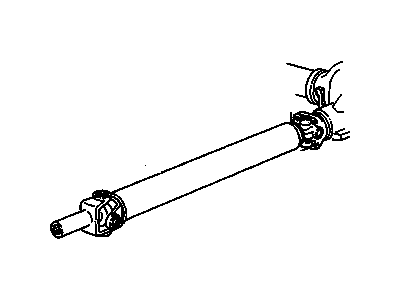

The part called the Universal Joint in GMC Jimmy automobiles is of great importance since its purpose is to join the driveshaft to the axle assembly in a manner that enables required pivoting due to the suspension movement in regard to the road. Used in flexible cable couplings to counter change in angle between connected units and smooth power transmission. in most cases the Universal Joint comprises a cross with needle bearings enclosed in hardened steel cups that are further clipped and usually come with a pre-filled grease. As for the years, the U Joint of GMC Jimmy vehicles has gone through different designs; most of the factory joints are pre-lubricated, while the sometimes contains grease zerks for replenishment. Worn U Joints can manifest themselves in such things as clunking noises during gear changes, and vibration at speed and therefore it must undergo inspection and in some cases replacement in other to uphold the performance of the vehicle.

GMC Jimmy Universal Joint Parts Questions & Experts Answers

- Q: What tools are needed to service and repair the universal joint with a nylon injected ring on GMC Jimmy?A:Service repair of universal joints with nylon injected rings requires these tools: Two main tools exist to handle this task: Universal Joint Bearing Separator (J 9522-3) and Universal Joint Bearing Spacer Remover (J 9522-5). Universal Joint Bearing Separator (J 9522-3) and Universal Joint Bearing Spacer Remover (J 9522-5). First support the propeller shaft horizontally on a press system without clamping the tubing inside a vise to preserve its condition. Last the propeller shaft ends with proper mark guidance. Keep the lower yoke ear of the universal joint fitting inside a 30 mm (1 1/8 inch) socket. The Universal Joint Bearing Separator (J 9522-3) enables a user to shear the plastic retaining ring on the bearing cup so they can press the lower bearing cup out of the yoke ear. Use the Universal Joint Bearing Spacer Remover (J 9522-5) between the seal and bearing cup if the cup is stuck before it can be fully pressed out. Use the propeller shaft rotation to push the bearing cup located on the opposite side out before removing the cross and all universal joint components. Evaluate retaining ring grooves along with bearing cup bores for damage while clearing away any plastic shearing that could prevent assembly. Begin assembly by mounting a bearing cup onto one yoke side followed by cross position adjustment so trunnions free fit. Apply force to each bearing cup until it sits seamlessly against the yoke ear before proceeding with the opposite side while maintaining correct trunnion position. Perform further inspection on needle bearings when you encounter binding resistance. Press until the bearing retainer groove emerges from the yoke before installing the bearing retainer while you snap both retainers into position with a dead blow hammer to support the seating process. Chassis grease can be used optionally for the snap ring to help it settle correctly within the bearing cup groove.