ChevyParts

My Garage

My Account

Cart

OEM GMC Sierra 3500 Classic Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Brake Lines found

GMC Sierra 3500 Classic Flex Hose, Front Driver Side Part Number: 19366683

$36.06 MSRP: $111.76You Save: $75.70 (68%)Ships in 1-2 Business Days

GMC Sierra 3500 Classic Flex Hose, Rear Part Number: 19366712

$39.54 MSRP: $76.74You Save: $37.20 (49%)Ships in 1-2 Business Days

GMC Sierra 3500 Classic Flex Hose, Rear Driver Side Part Number: 19366706

$49.03 MSRP: $95.16You Save: $46.13 (49%)Ships in 1-2 Business Days

GMC Sierra 3500 Classic Flex Hose, Rear Passenger Side Part Number: 19366705

$52.31 MSRP: $98.24You Save: $45.93 (47%)Ships in 1-2 Business Days

GMC Sierra 3500 Classic Flex Hose, Rear Passenger Side Part Number: 19366701

$47.49 MSRP: $92.18You Save: $44.69 (49%)Ships in 1-2 Business Days

GMC Sierra 3500 Classic Flex Hose, Rear Driver Side Part Number: 19366700

$48.39 MSRP: $90.88You Save: $42.49 (47%)Ships in 1-2 Business Days

GMC Sierra 3500 Classic Brake Line

Want to cut long-term maintenance and repair costs? Choose OEM Brake Line. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Sierra 3500 Classic parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Sierra 3500 Classic Brake Line includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Sierra 3500 Classic Brake Line Parts Questions & Experts Answers

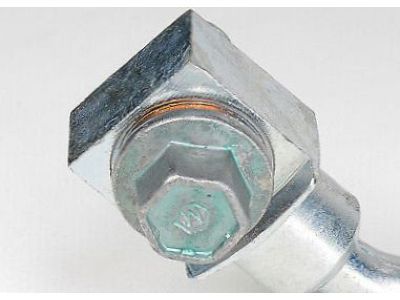

- Q: How to Service and Repair Brake Lines Using the Pipe Flaring Tool Kit (J 45405) on GMC Sierra 3500 Classic?A:In order to service and repair the brake pipes use the required tools, i.e., Pipe Flaring Tool Kit (J 45405). Start by checking the area where the brake pipe is to be replaced and remove it from the retainers that it may require. If sectioning the brake pipe do it in a suitable place that providing enough clearance, during the maneuvering the J 45405 except bends or mounting points. Measure the pipe that is going to replace, and let it be the length that goes with the additional length according to the pipe diameter and required flares. 6.35mm(0.250in) in case of 4.76mm(3/16in),9.50mm(0.374in) in case of 6.35mm(1/4 in) and so on and so forth for 12.67mm(0.499)in case of 7.94mm(5/16 in). Use the pipe cutter attached to the J 45405 to cut off the brake pipe precisely, and subsequently eliminate the cut part of the pipe. Choose the right size of brake pipe & tube nut, stripping the n.yl coating at the end of the one to flare using J 45405., tool the end coated parts should not gouged metal surface, so work carefully. Chamfer the internal and external diameter of the tube using the de-burring tool present in the J 45405 after which the tube nuts should be installed, clean the brake pipe and the J 45405 of any impurities, and loosen the die clamping screw. Mount the respective die set in the die cage, insert the pre-prepared pipe end, and secure it with the tightening of the clamping screw. Use the appropriate forming mandrel and operate the lever of J 45405 to make the flare them insert the finishing cone and repeat the process. Inspection of flare for correct shape and diameter after loosening die clamping screw. 6.74-7.10mm (0.265-0.279in) for 4.76mm (3/16in), 8.57-9.27mm (0.344-0.358 in) for 6.35mm (1/4 in), and 10.42-10.79mm (0.410-0.425 in) for 7.94mm (5/16 in). Bend the new pipe with an appropriate brake pipe folding tool if needed, keep a clearance of 19mm (3/4in) from all moving parts when fitting and secure the brake pipe, to the retainers. Finally bleed the hydraulic brake system while engine running and brakes apply, inspect flares in brake pipe for leakage.