ChevyParts

My Garage

My Account

Cart

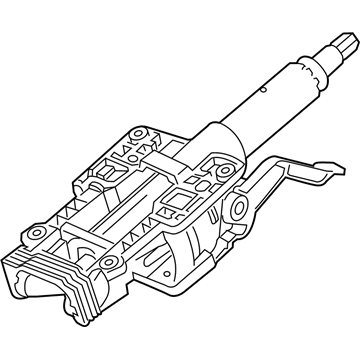

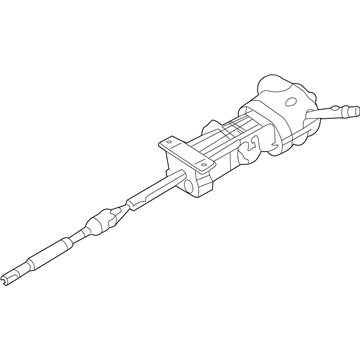

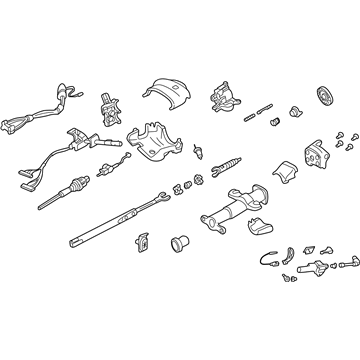

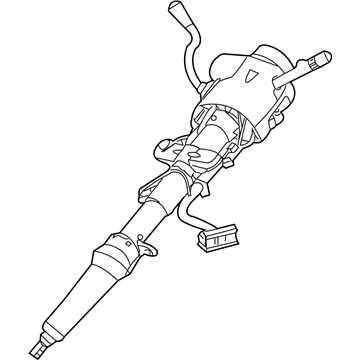

OEM GMC Steering Column

Steering Column Tilt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

225 Steering Columns found

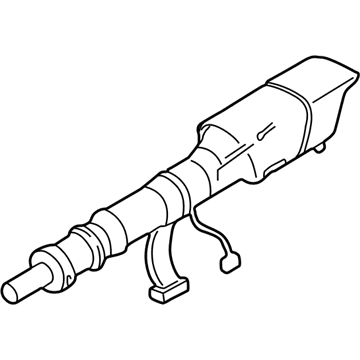

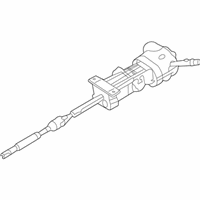

GMC Steering Column Part Number: 85665231

$155.56 MSRP: $244.78You Save: $89.22 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Column Assembly; Column, Steering

- Replaced by: 85010144

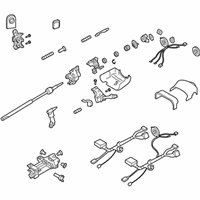

GMC Steering Column Part Number: 84828016

$196.85 MSRP: $309.76You Save: $112.91 (37%)Product Specifications- Other Name: Column Assembly; Column, Steering

GMC Steering Column Part Number: 84828017

$242.96 MSRP: $382.28You Save: $139.32 (37%)Product Specifications- Other Name: Column Assembly; Column, Steering

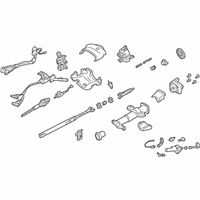

GMC Steering Column Part Number: 85542379

$634.07 MSRP: $1002.21You Save: $368.14 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Column Assembly; Column, Steering

- Replaces: 23409079, 84509189, 84036925, 84056879, 23221511, 84428961

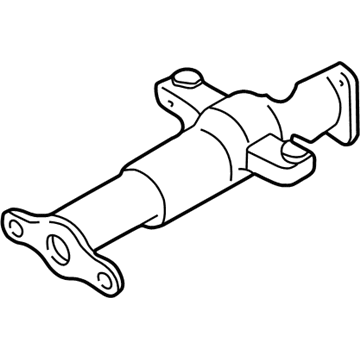

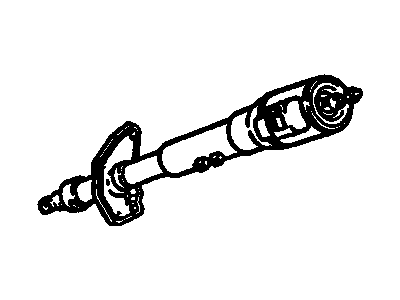

GMC Jacket Part Number: 26055681

$15.97 MSRP: $139.72You Save: $123.75 (89%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Jacket, Steering

GMC Steering Column Part Number: 15906793

Product Specifications- Other Name: Column; Column Assembly; Column, Steering

GMC Steering Column Part Number: 26037746

Product Specifications- Other Name: Column Assembly; Column, Steering

GMC Steering Column Part Number: 26043341

Product Specifications- Other Name: Clmn-Steering; Column, Steering

GMC Steering Column Part Number: 26050516

Product Specifications- Other Name: Clmn-Steering; Column Assembly; Column, Steering

GMC Jacket Part Number: 26055680

Product Specifications- Other Name: Jacket, Steering

GMC Steering Column Part Number: 26067538

Product Specifications- Other Name: Column; Column, Steering

GMC Steering Column Part Number: 26067539

Product Specifications- Other Name: Column; Column Assembly; Column, Steering

GMC Steering Column Part Number: 26067540

Product Specifications- Other Name: Column; Column Assembly; Column, Steering

GMC Column Assembly Part Number: 26067541

Product Specifications- Other Name: Column; Steering Column; Column, Steering

GMC Steering Column Part Number: 26074475

Product Specifications- Other Name: Column; Column Assembly; Column, Steering

GMC Column Assembly Part Number: 26074476

Product Specifications- Other Name: Column; Steering Column; Column, Steering

GMC Steering Column Part Number: 26084305

Product Specifications- Other Name: Column; Column, Steering

GMC Steering Column Part Number: 26094743

Product Specifications- Other Name: Column; Column Assembly; Column, Steering

GMC Steering Column Part Number: 19180612

Product Specifications- Other Name: Column Assembly; Column, Steering

GMC Steering Column Part Number: 26030418

Product Specifications- Other Name: Column Assembly; Column, Steering

| Page 1 of 12 |Next >

1-20 of 225 Results

GMC Steering Column

Want to cut long-term maintenance and repair costs? Choose OEM Steering Column. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Steering Column includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Steering Column Parts Questions & Experts Answers

- Q: What should be inspected on those involved in accidents to determine if the steering column is damaged or misaligned on GMC Canyon?A:Accidents that lead to frame damage along with major body damage and sheet metal damage together with impacts on the Steering Column or triggering of supplemental inflatable restraints systems typically result in misaligned steering columns. A complete inspection must verify that all capsules are correctly attached to their bracket slots before examining the system's loose conditions by manual pressure tests. The maintenance decision depends on bracket installation method; change only the bracket when it bolts to jacket assembly yet switch out jacket assembly when bracket welding exists. The distance between the lower edge of the upper jacket and defined point on the lower jacket must be measured for jacket assembly collapse evaluation. A replacement jacket assembly is necessary if measurements fall outside specified parameters. Pull out the inflatable restraint coil assembly from the Steering Column then let it dangle in free space to protect the coil assembly from harm before turning the shaft. A visual examination for sheared plastic in the Steering Shaft should be performed; replacement of the shaft is required in case sheared plastic is found. To detect incorrect Steering Shaft runout a dial indicator should be applied at the shaft bottom while wheel rotation with a maximum tolerance of 1.60 mm (0.06 inch).

- Q: How Can a Collision Affect the Steering Column and What Inspections Are Necessary on GMC Envoy?A:Damage to a vehicle frame along with major body or sheet metal damage and impact to the Steering Column or deployment of supplemental inflatable restraint systems can cause a misaligned Steering Column. All capsules on the Steering Column bracket assembly need to be checked to confirm their proper seat within bracket slots while also conducting a manual check for loose conditions. Brackets get swapped individually except when capsules stay loose and the bracket connects to the jacket structurally by bolt. The whole jacket assembly needs replacement under this scenario. The first step requires checking tab fractures on the bearing and adapter assembly followed by inspecting the Steering Shaft for sheared plastic material. If sheared plastic exists the Steering Shaft needs immediate replacement. Steering Shaft runout needs to be evaluated through a dial indicator check at the Steering Shaft bottom end when steering wheel rotation occurs. This evaluation must demonstrate less than 1.60 mm (0.06 in) runout.

- Q: How to Inspect and Repair a Damaged or Misaligned Steering Column on GMC Jimmy?A:Accidents that lead to frame degeneration or major body damage or sheet metal harm as well as Steering Column contact or activation of the supplemental inflatable restraint system may damage or misalign the Steering Column. Check the capsules on the Steering Column bracket assembly for secure bracket slot seating and inspect for looseness by manual hand pressure; replace the bracket through the jacket when bolted or replace the jacket when bracket welding is present. Verify jacket assembly collapse by checking the distance from upper to lower jacket edges at defined points; obtain a new jacket if measurements exceed specifications. Rotation of the shaft needs the inflatable restraint coil assembly to be removed from the Steering Column due to preventing coil assembly damage while hanging freely. The inspection of the Steering Shaft needs to be conducted visually to check for sheared injected plastic. Install a new Steering Shaft if sheared plastic is found. A dial indicator should be used to check the Steering Shaft runout at the bottom end during steering wheel rotation before continuing since runout should be 1.60 mm or less.

Related GMC Parts

Browse GMC Steering Column by Models

Acadia Sierra 1500 Yukon Canyon Sierra 2500 HD Terrain Envoy Sonoma Typhoon Syclone C1500 Envoy XL Envoy XUV Jimmy K1500 S15 S15 Jimmy Safari Savana 2500 Savana 3500 Sierra 2500 Sierra 3500 Yukon XL Acadia Limited C2500 C3500 G2500 K2500 K3500 P3500 Savana 1500 Yukon XL 1500 C1500 Suburban C2500 Suburban G1500 G3500 K1500 Suburban K2500 Suburban P2500 R1500 R1500 Suburban R2500 R2500 Suburban R3500 Sierra 1500 Classic Sierra 1500 HD Sierra 1500 HD Classic Sierra 1500 Limited Sierra 2500 HD Classic Sierra 3500 Classic Sierra 3500 HD V1500 V1500 Suburban V2500 V2500 Suburban V3500 Yukon XL 2500