ChevyParts

My Garage

My Account

Cart

OEM 2008 GMC Canyon Pinion Bearing

Transmission Pinion Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Pinion Bearings found

2008 GMC Canyon Side Bearings Part Number: 25824250

$73.65 MSRP: $142.94You Save: $69.29 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Side Gear; Differential Pinion Bearing; Differential Bearing

- Replaces: 09418390, 9418390

- Item Weight: 1.20 Pounds

- Item Dimensions: 4.3 x 4.3 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 25824250

- Warranty: This genuine part is guaranteed by GM's factory warranty.

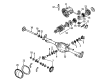

2008 GMC Canyon Pinion Bearings, Inner Part Number: 22510042

$44.26 MSRP: $130.98You Save: $86.72 (67%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Drive Pinion Gear Inner; Differential Pinion Bearing; Rear Pinion Bearing; Front Pinion Bearing; Inner Pinion Bearing; Differential Drive Pinion Bearings.

- Position: Inner

- Item Weight: 1.90 Pounds

- Item Dimensions: 3.5 x 3.6 x 1.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 22510042

- Warranty: This genuine part is guaranteed by GM's factory warranty.

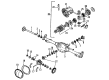

2008 GMC Canyon Pinion Bearings Part Number: 23243839

$72.64 MSRP: $142.22You Save: $69.58 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Pinion; Differential Pinion Bearing; Rear Pinion Bearing; Front/Inner/Outer Pinion; Diff/Drive Axle; Pinion/Clutch/Rear Wheel

- Position: Front

- Replaces: 09418357, 26053758, 9418357, 15286375, 20997052, 22786621, 9418356, 09418356, 12479221

- Item Weight: 1.30 Pounds

- Item Dimensions: 4.2 x 4.2 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 23243839

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2008 GMC Canyon Pinion Bearings Part Number: 9417784

$24.86 MSRP: $68.16You Save: $43.30 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pinion Gear Front; Differential Pinion Bearing; Axle Bearing; Rear Pinion Bearing; Front Pinion Bearing; Outer Pinion Bearing; Differential Drive Pinion Bearing; Front Axle Bearing.

- Position: Outer

- Item Weight: 1.10 Pounds

- Item Dimensions: 3.0 x 3.0 x 1.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 9417784

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2008 GMC Canyon Pinion Bearing

With a comprehensive array of OEM 2008 GMC Canyon Pinion Bearing, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2008 GMC Canyon Pinion Bearing are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2008 GMC Canyon Pinion Bearing Parts Questions & Experts Answers

- Q: How to replace the drive pinion bearings on an 8.0 Inch Axle on 2008 GMC Canyon?A: Raising the vehicle represents the first step to handle drive Pinion Bearing replacement on an 8.0 inch axle. First remove the Differential part from the axle followed by detaching the drive pinion. The j 22912-b instrument presses the bearing off the pinion before the shim removal process begins. Install the Pinion Bearing cups by using a hammer with brass drift to perform gentle side-to-side motions on the outer cup followed by drilling of the inner cup. The sequence to install Pinion Bearing cups starts with using j 7817 (Outer Bearing Race Installer) and j 8092 (Universal Driver Handle- 3/4 in - 10) followed by installing the outer cup and then using j 8608 (Rear Pinion Bearing Race Installer) and j 8092 (Universal Driver Handle- 3/4 in - 10) to install the inner cup. Select the required shim thickness for the pinion components before placing it between the inner bearing and gear shoulder. Install the inner Pinion Bearing through the j 24433 (Pinion Cone and Side Bearing Installer) tool until it reaches the shim position before adding a replacement collapsible spacer. Use necessary axle lubricant to lubricate both pinion bearings before installing the pinion inside the axle housing followed by insertion of the outer Pinion Bearing onto its position on the pinion. Service technicians should install the pinion oil seal with the j 33782 tool after applying sealant gm p/n 12346004 (Canadian P/N 10953480) to the pinion yoke on the marked splines of the yoke. Use a soft-faced hammer to set the pinion yoke on the pinion shaft until it shows a few threads and install the washer followed by a new pinion nut. Use the j 8614-01 (Flange and Pulley Holding Tool) to sustain the pinion yoke position while tightening the nut until the pinion end play reaches complete absorption while rotating the pinion to have the bearings properly seated. Test the torque intensity with an inch-pound torque wrench for used bearings between 1.0-2.8 n.m and 1.7-3.4 n.m for new bearings. Continue tightening the pinion nut by small increments until it reaches the correct measurement at 1.0 to 2.8 n.m (10 to 25 lb in). The pinion should be rotated several times once you reach the specified torque value for bearing seating verification before final torque recheck and potential adjustments. After installation of the Differential it is necessary to fill the axle with proper axle lubricant before bringing the vehicle to its normal position.