ChevyParts

My Garage

My Account

Cart

OEM 2010 GMC Canyon Pinion Bearing

Transmission Pinion Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Pinion Bearings found

2010 GMC Canyon Side Bearings Part Number: 25824250

$73.65 MSRP: $142.94You Save: $69.29 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Side Gear; Differential Pinion Bearing; Differential Bearing

- Replaces: 09418390, 9418390

- Item Weight: 1.20 Pounds

- Item Dimensions: 4.3 x 4.3 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 25824250

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2010 GMC Canyon Pinion Bearings, Inner Part Number: 22510042

$44.26 MSRP: $130.98You Save: $86.72 (67%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Drive Pinion Gear Inner; Differential Pinion Bearing; Rear Pinion Bearing; Front Pinion Bearing; Inner Pinion Bearing; Differential Drive Pinion Bearings.

- Position: Inner

- Item Weight: 1.90 Pounds

- Item Dimensions: 3.5 x 3.6 x 1.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 22510042

- Warranty: This genuine part is guaranteed by GM's factory warranty.

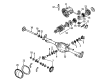

2010 GMC Canyon Pinion Bearings Part Number: 23243839

$72.64 MSRP: $142.22You Save: $69.58 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing, Differential Pinion; Differential Pinion Bearing; Rear Pinion Bearing; Front/Inner/Outer Pinion; Diff/Drive Axle; Pinion/Clutch/Rear Wheel

- Position: Front

- Replaces: 09418357, 26053758, 9418357, 15286375, 20997052, 22786621, 9418356, 09418356, 12479221

- Item Weight: 1.30 Pounds

- Item Dimensions: 4.2 x 4.2 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 23243839

- Warranty: This genuine part is guaranteed by GM's factory warranty.

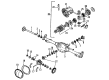

2010 GMC Canyon Pinion Bearings Part Number: 9417784

$24.86 MSRP: $68.16You Save: $43.30 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pinion Gear Front; Differential Pinion Bearing; Axle Bearing; Rear Pinion Bearing; Front Pinion Bearing; Outer Pinion Bearing; Differential Drive Pinion Bearing; Front Axle Bearing.

- Position: Outer

- Item Weight: 1.10 Pounds

- Item Dimensions: 3.0 x 3.0 x 1.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 9417784

- Warranty: This genuine part is guaranteed by GM's factory warranty.

2010 GMC Canyon Pinion Bearing

With a comprehensive array of OEM 2010 GMC Canyon Pinion Bearing, from fuel pumps to door handles, our website is a one-stop-shop for your needs. All our genuine 2010 GMC Canyon Pinion Bearing are backed by the manufacturer's warranty and are offered at competitive prices in the market. Rest assured, you can shop with complete confidence.

2010 GMC Canyon Pinion Bearing Parts Questions & Experts Answers

- Q: How to service and repair the front drive axle's pinion bearing on 2010 GMC Canyon?A: The procedure to service and repair the Pinion Bearing of the front drive axle begins with vehicle lift before Differential carrier assembly removal. Prepare a (J 22536) on the pinion before fixing it in place and striking it with a hammer to extract it while preventing it from slipping out of the rear axle housing. Open the collapsible spacer while removing the pinion bearings with their cups before taking off the ring gear. Clean the mating surface between the ring gear and Differential case after which the new ring gear bolts can be installed by hand-starting them one-by-one to check alignment before torquing them alternately at 120 nm (89 lb ft). Determine the selective shim thickness for the pinion gear before installing the drive Pinion Bearing cups. The installation process begins with the selective shim placed on the pinion until the inner Pinion Bearing receives placement with a new collapsible spacer after which pinion bearings receive axle lubricant. Put the pinion inside the axle housing before attaching the outer Pinion Bearing and a fresh pinion oil seal through tool (J 21128). Apply sealant to the splines of the pinion yoke then install it according to the removal marks while soft-facing hammer taps help seat the yoke properly. You should use (J 8614-01) to maintain pinion yoke position before tightening the new pinion nut until the pinion end play reaches a proper seating. The pinion torque requires measurement while the pinion end play remains just taken up. Use a torque wrench to check for rotating torques between 1.0 - 2.3 nm (10 - 20 lb in) for used bearings and 1.7 - 3.4 nm (15 - 30 lb in) for new bearings before necessary adjustments. Achieve the required torque on the pinion then spin it several times to ensure optimal bearing seating before putting on the Differential carrier and conducting a pinion-ring gear tooth contact pattern check. A 4.318 mm (0.170 in) thick service spacer must be inserted into the left side of the axle housing before sliding the Differential assembly towards it when performing Differential side bearing preload adjustment. Measure the right side Differential side bearing cup's thickness using tool (J 22779) before obtaining an average value. The (J 22779) will be utilized to adjust the backlash on the right side to a range of 0.025-0.051 mm (0.001-0.002 in), starting from a right-side shim of 1.016 mm (0.040 in) and then adding a bent shim. Measure the tool in three locations after removal to get left service shim thickness without preload and then perform right side calculation. Organize both shim packs and install the Differential assembly before torquing the Differential bearing cap bolts to 63 nm (46 lb ft). Check the drive pinion and Differential side bearing preload numbers then change the shim thickness if needed to maintain specifications. A gear tooth contact pattern evaluation serves as the last step to validate proper ring and pinion gear alignment.