ChevyParts

My Garage

My Account

Cart

OEM Buick A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

36 A/C Clutches found

Buick Pulley Part Number: 6552284

$140.68 MSRP: $252.35You Save: $111.67 (45%)Product Specifications- Other Name: Pulley-W/Rotor & Bearing (5.0") P.V.; A/C Compressor Clutch

- Replaced by: 06580047

Buick Coil Assembly Part Number: 89019186

$34.63 MSRP: $102.48You Save: $67.85 (67%)Product Specifications- Other Name: Coil, Air Conditioner Compressor Clutch Actuating; A/C Compressor Clutch; Clutch Coil; Clutch Coil Assembly; Coil & Wire Assembly; Clutch; Coil; Coil, A/C Compressor Clutch Actuating

- Replaces: 6552423, 06552423

Buick Clutch Drive, Front Part Number: 6552372

$64.19 MSRP: $119.78You Save: $55.59 (47%)Product Specifications- Other Name: Clu Front Assembly; A/C Compressor Clutch; Clutch

- Position: Front

- Replaced by: 6581515

Buick Coil Assembly Part Number: 89019185

Product Specifications- Other Name: Coil Assembly, A/C Clutch; A/C Compressor Clutch; Clutch Coil; Clutch Coil Assembly; Coil; Coil, A/C Compressor Clutch Actuating

- Replaces: 06552422, 6552422

Buick Coil Assembly Part Number: 6552649

Product Specifications- Other Name: Coil, A/C Compressor Clutch; Clutch Coil; A/C Compressor Clutch Assembly; Coil & Wire Assembly

Buick Rotor & Bearing Part Number: 2724722

Product Specifications- Other Name: Rotor, A/C Clutch; A/C Compressor Clutch; Rotor; Rotor, A/C Compressor (Internal Parts)

Buick Compressor Pulley Part Number: 6557503

Product Specifications- Other Name: R4 Pulley; A/C Compressor Clutch; Pulley

Buick Clutch Drive Part Number: 6551717

Product Specifications- Other Name: Clutch Drive Assembly; A/C Compressor Clutch; Clutch

Buick Clutch Part Number: 89018605

Product Specifications- Other Name: Clutch Kit, A/C; A/C Compressor Clutch

- Replaces: 10311311

Buick Clutch Kit Part Number: 84364333

$122.61 MSRP: $219.92You Save: $97.31 (45%)Product Specifications- Other Name: Clutch Kit, Air Conditioner Compressor Clutch; A/C Compressor Clutch; Clutch & Pulley; Clutch; Clutch Kit, A/C Compressor Clutch

- Replaced by: 85641373

- Replaces: 23393433

Buick Coil Assembly Part Number: 6550835

Product Specifications- Other Name: Clutch Coil/H; A/C Compressor Clutch; Clutch Coil; Cluster Assembly; Coil & Wire Assembly; Clutch; Coil; Coil, A/C Compressor Clutch Actuating

Buick Coil Part Number: 6552289

Product Specifications- Other Name: Coil, W/Housing Assembly; A/C Compressor Clutch

Buick Hub Assembly Part Number: 5914719

Product Specifications- Other Name: Clutch, A/C; A/C Compressor Clutch; Clutch & Pulley; Drive Assembly; Coil; Compressor Plate; Hub Assembly; A/C Actuating.

Buick Coil Assembly Part Number: 89019188

Product Specifications- Other Name: Coil Assembly, A/C Clutch; A/C Compressor Clutch; Clutch Coil; Clutch Coil Assembly; Coil & Wire Assembly; Clutch; Coil; Coil, A/C Compressor Clutch Actuating

- Replaces: 6552155, 06551997, 6551997

Buick Clutch Coil Part Number: 3091128

Product Specifications- Other Name: Coil & Housing Assembly (High-Amp); A/C Compressor Clutch; Clutch Coil Assembly; Coil & Wire Assembly; Coil

Buick Clutch Part Number: 89018518

Product Specifications- Other Name: Clutch Kit, A/C; A/C Compressor Clutch; Clutch Kit, A/C Compressor Clutch

Buick Clutch Part Number: 10311310

Product Specifications- Other Name: Clutch Assembly-A/C; A/C Compressor Clutch; Clutch, A/C Compressor Clutch

Buick Compressor Pulley Part Number: 6580546

Product Specifications- Other Name: Pulley, A/C Compressor; A/C Compressor Clutch; Pulley W/Bearing; Pulley; Pulley, A/C Compressor Drive/Idler

Buick Clutch & Pulley Part Number: 84160278

$124.95 MSRP: $224.12You Save: $99.17 (45%)Product Specifications- Other Name: Clutch Kit, Air Conditioner Compressor Clutch; A/C Compressor Clutch; Clutch; Clutch Kit, A/C Compressor Clutch

Buick Clutch Assembly Part Number: 86807268

$246.59 MSRP: $442.34You Save: $195.75 (45%)Product Specifications- Other Name: Clutch Kit, Air Conditioner Compressor Clutch; Clutch; Clutch Kit, A/C Compressor Clutch

- Replaces: 15926084

| Page 1 of 2 |Next >

1-20 of 36 Results

Buick A/C Clutch

Want to cut long-term maintenance and repair costs? Choose OEM A/C Clutch. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick A/C Clutch includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

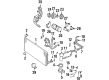

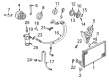

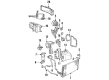

Buick A/C Clutch Parts Questions & Experts Answers

- Q: How to Properly Service and Replace the A/C Clutch on Buick LaCrosse?A:You must remove the accessory Drive Belt from both the A/C Compressor and the lower air deflector before performing removal of the compressor clutch assembly. Important: for the j 37872 (Compressor Clutch Holding Tool) replace the three adjust d dowels with three 5/16x1 inch bolts. The j 37872 (Compressor Clutch Holding Tool) holds the compressor clutch plate stationary while the bolt is discarded before clutch plate removal. Use j 6083 (Snap Ring Pliers) to remove the compressor pulley snap ring then remove the compressor pulley from the compressor before performing the same sequence for the compressor clutch coil snap ring and coil. Before compressor clutch plate bolt installation you must tap its threads with an m6x1.0 tap before blowing out any debris with compressed air. The installation of the compressor clutch coil and its snap ring should be performed with the j 6083 (Snap Ring Pliers) while subsequent installation of the compressor pulley and its snap ring requires the same tool (J 6083 (Snap Ring Pliers)). Place a small amount of oil on the 0.4 mm (0.016 in) air gap shim before setting it inside the clutch drive plate while you install the compressor clutch plate. Important: make sure the drive plate avoids contact with the pulley when you rotate it. Adjust the shims to create a 0.3 to 0.6 mm (0.012 to 0.024 in) air gap by measuring the spacings between the pulley and drive plate. Important: new drive plate bolts must contain colored adhesive for five threads before final installation. Notice: fastener notice applies. Each compressor clutch drive plate bolt installation requires the use of the j 37872 (Compressor Clutch Holding Tool) to prevent clutch plate movement before securing the bolt at 12 n.m (106 lb in). To complete the procedure reinstall the lower air deflector followed by installing the accessory Drive Belt to the A/C Compressor then conduct a leak test on all fittings using the j 39400-a (Halogen Leak Detector).