ChevyParts

My Garage

My Account

Cart

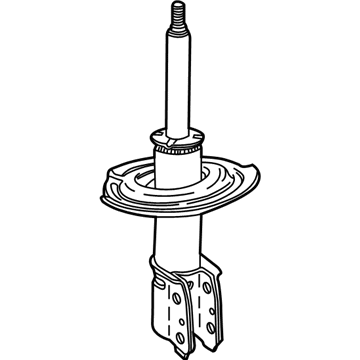

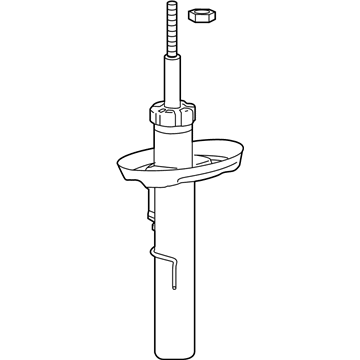

OEM Buick Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

256 Shock Absorbers found

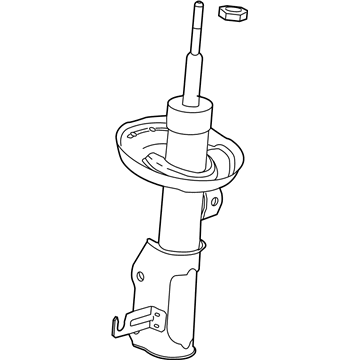

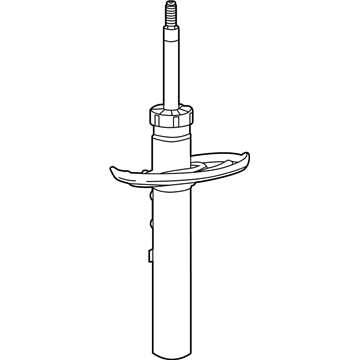

Buick Strut, Driver Side Part Number: 23390195

$155.50 MSRP: $304.44You Save: $148.94 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Strut, Front and Rear Suspension; Complete Strut and Shock Absorber Assembly Kit.

- Position: Driver Side

- Replaces: 23125724, 20944653, 22968750

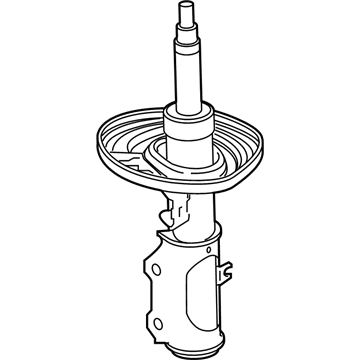

Buick Strut, Passenger Side Part Number: 23390196

$241.72 MSRP: $469.19You Save: $227.47 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Strut, Front and Rear Suspension; Complete Strut and Shock Absorber Assembly Kit.

- Position: Passenger Side

- Replaces: 22968749, 23125725, 20944652

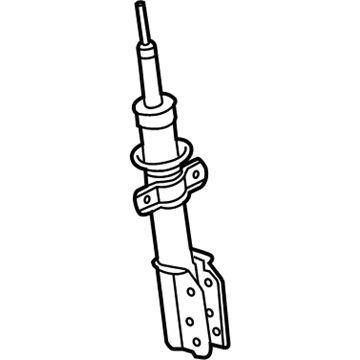

Buick Strut, Driver Side Part Number: 13390275

$116.80 MSRP: $228.70You Save: $111.90 (49%)Product Specifications- Other Name: Strut, Front And Rear Suspension; Shock Absorber

- Position: Driver Side

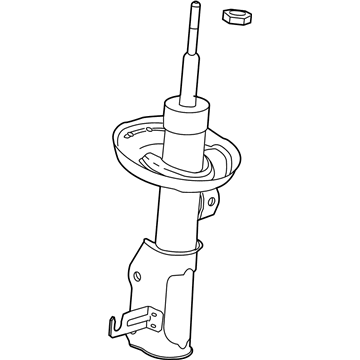

Buick Strut Part Number: 89047814

$77.08 MSRP: $228.19You Save: $151.11 (67%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Strut, Front and Rear Suspension; Complete Strut Assembly Kit; Shock Absorber.; Strut Kit, Front And Rear Suspension

- Position: Rear

Buick Strut Part Number: 13310728

$282.79 MSRP: $511.85You Save: $229.06 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Strut, Front and Rear Suspension; Complete Suspension Strut and Shock Absorber Assembly Kit.

- Position: Front

Buick Strut, Passenger Side Part Number: 13330741

$50.94 MSRP: $197.44You Save: $146.50 (75%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Strut, Front and Rear Suspension; Complete Strut and Shock Absorber Assembly Kit.

- Position: Passenger Side

Buick Shock Absorber, Driver Side Part Number: 22744712

$184.73 MSRP: $346.92You Save: $162.19 (47%)Product Specifications- Other Name: Suspension Strut and Shock Absorber Assembly Kit; Suspension Strut Assembly Kit; Strut Shock Kit; Complete Strut; Shock; Absorber, Front And Rear Suspension

- Position: Driver Side

Buick Strut, Passenger Side Part Number: 84447271

$302.18 MSRP: $567.48You Save: $265.30 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Strut, Front And Rear Suspension; Shock Absorber

- Position: Passenger Side

- Replaces: 84042278, 84210230

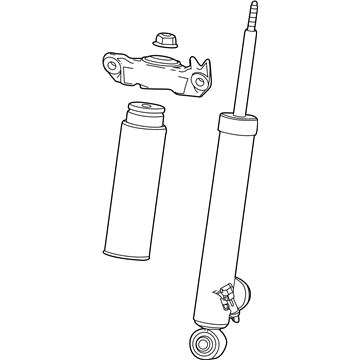

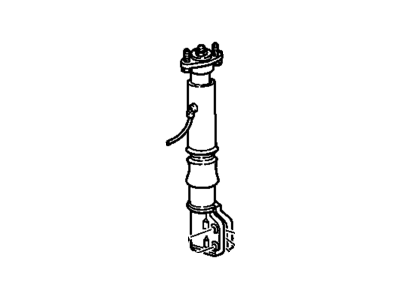

Buick Shock Absorber, Rear Upper Passenger Side Part Number: 84545215

$86.09 MSRP: $161.67You Save: $75.58 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber Assembly-Rear Shock (W/Upper Mount); Shock; Absorber, Front And Rear Suspension

- Position: Rear Upper Passenger Side

- Replaces: 22961778, 20859319

Buick Shock Absorber, Rear Upper Passenger Side Part Number: 22932446

$74.85 MSRP: $139.69You Save: $64.84 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber Assembly-Rear Shock (W/Upper Mount); Suspension Strut and Shock Absorber Kit; Complete Strut.; Shock; Absorber, Front And Rear Suspension

- Position: Rear Upper Passenger Side

Buick Strut, Driver Side Part Number: 84447268

$276.04 MSRP: $540.47You Save: $264.43 (49%)Product Specifications- Other Name: Strut, Front And Rear Suspension; Shock Absorber

- Position: Driver Side

- Replaces: 84042279, 84210231

Buick Strut Part Number: 89060255

$93.95 MSRP: $182.37You Save: $88.42 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Strut Assembly, Front Suspension; Complete Strut Kit; Shock Absorber.; Strut, Front And Rear Suspension

- Position: Front

Buick Shock Absorber, Rear Upper Driver Side Part Number: 22932444

$178.22 MSRP: $329.74You Save: $151.52 (46%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber Assembly-Rear Shock (W/Upper Mount); Suspension Strut and Shock Absorber Kit; Complete Strut.; Shock; Absorber, Front And Rear Suspension

- Position: Rear Upper Driver Side

Buick Strut, Passenger Side Part Number: 13328352

$276.65 MSRP: $511.86You Save: $235.21 (46%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Strut, Front and Rear Suspension; Complete Strut and Shock Absorber Assembly Kit.

- Position: Passenger Side

Buick Strut, Driver Side Part Number: 13328351

$277.31 MSRP: $513.07You Save: $235.76 (46%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Strut, Front and Rear Suspension; Complete Strut and Shock Absorber Assembly Kit.

- Position: Driver Side

Buick Shock Absorber, Rear Part Number: 22064107

$33.01 MSRP: $138.68You Save: $105.67 (77%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Strut Assembly-Rear Suspension; Suspension Strut Assembly Kit; Air Suspension Strut; Complete Strut Kit; Complete Strut; Strut; Strut, Front And Rear Suspension

- Position: Rear

Buick Strut Part Number: 22969021

$63.84 MSRP: $175.47You Save: $111.63 (64%)Product Specifications- Other Name: Strut, Front and Rear Suspension; Complete Suspension Strut and Shock Absorber Assembly Kit.

- Position: Front

- Replaces: 22787927, 19210788

Buick Strut, Driver Side Part Number: 84447270

$310.17 MSRP: $556.37You Save: $246.20 (45%)Product Specifications- Other Name: Strut, Front And Rear Suspension; Shock Absorber

- Position: Driver Side

- Replaces: 84042277, 84210229

Buick Strut Part Number: 15898772

$368.98 MSRP: $661.84You Save: $292.86 (45%)Product Specifications- Other Name: Strut Kit, Front And Rear Suspension; Shock Absorber; Absorber, Front And Rear Suspension

- Position: Front

Buick Strut Part Number: 23390197

Product Specifications- Other Name: Strut, Front And Rear Suspension; Suspension Strut and Shock Absorber Assembly Kit; Shock Absorber Set.

- Position: Front

- Replaces: 23144452

| Page 1 of 13 |Next >

1-20 of 256 Results

Buick Shock Absorber

Choose OEM Shock Absorber, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Buick's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsGiant.com, you'll find it easy to get top-quality OEM Buick Shock Absorber. You can shop at highly competitive prices and protect your budget. All our genuine Buick parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Buick Shock Absorber Parts and Q&A

- Q: How should one safely handle gas charged shock absorbers during maintenance on Buick Enclave?A:The snap ring within your gas charged shock absorber tube contains high pressure gas so removing it poses a safety risk of severe gas expulsion. Safety glasses and caution toward the shock absorber tube should be used to prevent injuries when performing spot drilling and center punching activities. A centerpunch should create a 10 mm (0.4 in) long indentation at the tube bottom prior to processing. Place the shock absorber inside a vise with its rod extended while keeping it horizontal position. Drill a 5 mm (3/16 in) hole at the centerpunch location while exhaust gas with potential oil mixture escapes through shop towels for containment. The second hole needs drilling at the middle centerpunch indentation using a 5 mm (3/16 in) bit to drain the shock absorber oil while shop towels protect against eventual liquid spillage. After releasing the shock absorber from the vise angle it with drain holes facing down and insert the shaft to pull out all remaining fluid from the tube.

- Q: What Tools Are Required to Service and Repair the Shock Absorber on Buick Regal?A:For servicing and repairing the suspension strut, the following tools and equipment are necessary: Strut Spring Compressor (J 34013-B), Damper Rod Clamp (J 34013-20), Alignment Rod (J 34013-197), Upper Strut Adapter (J 34013-125), Lower Strut Adapter (J 3401 Start by taking the strut off the vehicle and mounting it to the Strut Spring Compressor (J 34013-B) with the use of wing nuts at the mounting holes C and E/K, with the wide end of the adapter facing outboard. Bring the Lower Strut Adapter (J 34013-971) and Upper Strut Adapter (J 34013-125) into alignment for proper opening and closing. Install the strut in the adapters, close them and mount locking pins through the holes on the Strut Spring Compressor (J 34013-B) as well as the strut's mounting holes. Care to prevent excess spring compression and tool failure. Unscrew Strut Spring Compressor (J 34013-B) opposite of clockwise to lift the strut and compress the spring by 13mm (0.50inch) or 3-4 full rotations. Remove the strut nut, using the strut rod nut socket (j 42991), while holding the shaft with a T-45 TORX(R) bit and discard the strut nut and relieve the spring compression. To assemble, fasten the strut to the Strut Spring Compressor (J 34013-B) once again, and install the spring with correct positions of the upper and lower spring seats. Compress the spring slowly while threading the strut shaft through the top of the spring while ensuring that the Alignment Rod (J 34013-197) is straight with the strut. Install a new strut nut to the strut rod, torque to 75 Nm (55 ft. lbs.) with the Strut Rod Nut Socket (J 42991) while holding the shaft with a T-45 TORX® bit. Lastly, take all tools out of the Strut Spring Compressor (J 34013-B) and return the strut to the automobile, then readjust the rear wheel alignment.