ChevyParts

My Garage

My Account

Cart

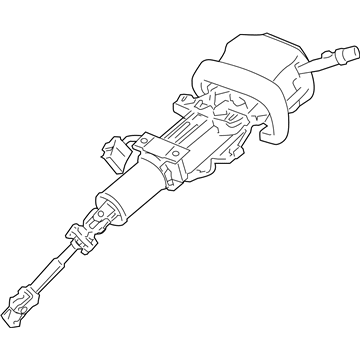

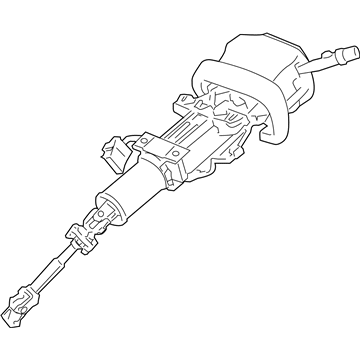

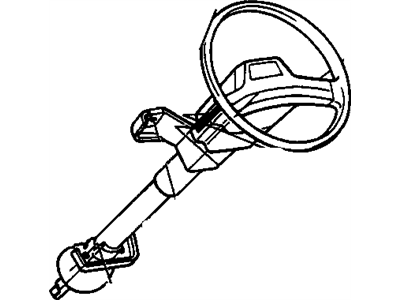

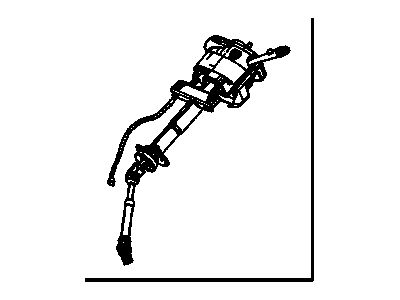

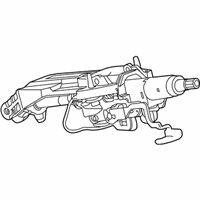

OEM Buick Steering Column

Steering Column Tilt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

177 Steering Columns found

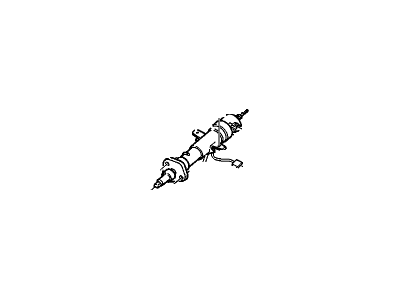

Buick Steering Column, Gray Part Number: 15918260

$106.33 MSRP: $811.52You Save: $705.19 (87%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Column, Steering

Buick Steering Column Part Number: 25999436

$113.44 MSRP: $841.92You Save: $728.48 (87%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Column, Steering

- Replaces: 15918376

Buick Steering Column, Titanium Part Number: 25999446

$147.01 MSRP: $973.25You Save: $826.24 (85%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Column, Steering

- Replaces: 15918418

Buick Steering Column, Gray Part Number: 15918377

$137.75 MSRP: $1022.35You Save: $884.60 (87%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Column, Steering

Buick Steering Column Part Number: 26007818

Product Specifications- Other Name: Column Assembly; Column, Steering

Buick Steering Column Part Number: 26026162

Product Specifications- Other Name: Column Assembly; Column, Steering

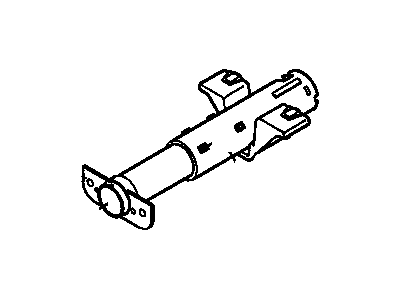

Buick Jacket Assembly Part Number: 26031420

Product Specifications- Other Name: Jacket, Seat; Jacket; Jacket, Steering

Buick Steering Column Part Number: 26040436

Product Specifications- Other Name: Column Assembly; Column, Steering

Buick Steering Column Part Number: 26040440

Product Specifications- Other Name: Column Assembly; Column, Steering

Buick Jacket Assembly Part Number: 26042693

Product Specifications- Other Name: Jacket, Seat; Jacket; Jacket, Steering

Buick Steering Column Part Number: 26081204

Product Specifications- Other Name: Column; Column, Steering

Buick Jacket Assembly Part Number: 26042712

Product Specifications- Other Name: Jacket, Steering; Jacket

Buick Steering Column Part Number: 39019158

Product Specifications- Other Name: Column Assembly; Column, Steering

- Replaces: 23326901, 13344988, 13426749, 13404506, 23287104

Buick Jacket Part Number: 26045684

Product Specifications- Other Name: Jacket, Steering

Buick Steering Column Part Number: 25999438

Product Specifications- Other Name: Column, Steering

- Replaces: 15918379

Buick Steering Column Part Number: 25999447

Product Specifications- Other Name: Column, Steering

- Replaces: 15918419

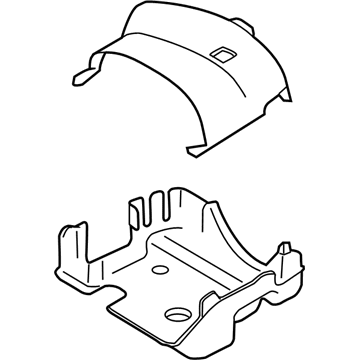

Buick Cover Assembly Part Number: 25999441

Product Specifications- Other Name: Column, Steering

Buick Steering Column, Gray Part Number: 15247331

Product Specifications- Other Name: Column Assembly-Steering *Gray Y; Column, Steering

Buick Steering Column Part Number: 25999442

Product Specifications- Other Name: Column, Steering

- Replaces: 15918406

Buick Steering Column, Gray Part Number: 15918417

Product Specifications- Other Name: Column, Steering

| Page 1 of 9 |Next >

1-20 of 177 Results

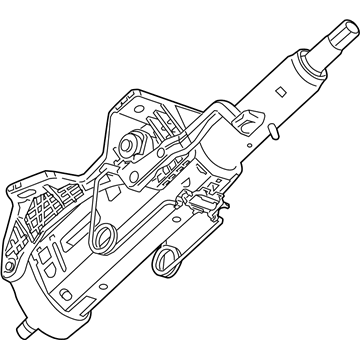

Buick Steering Column

Choose OEM Steering Column, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Buick's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsGiant.com, you'll find it easy to get top-quality OEM Buick Steering Column. You can shop at highly competitive prices and protect your budget. All our genuine Buick parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

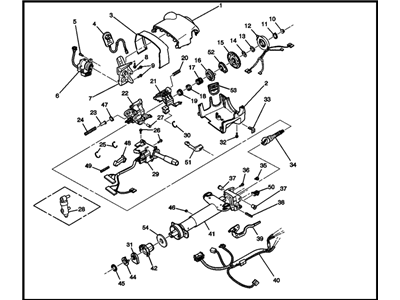

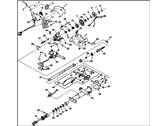

Buick Steering Column Parts and Q&A

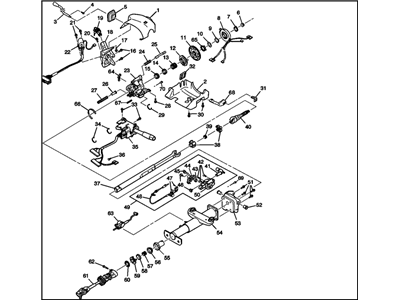

- Q: How should you inspect the capsules on the steering column bracket assembly after a collision on Buick Enclave?A:The inspection of steering column bracket assembly capsules should check that they fit securely into bracket slots while visually evaluating looseness using hand tests. Replace the bracket when it is bolted to the jacket assembly because the capsules remain insecure. Alternatively change the jacket assembly if it is welded to this assembly. Measure the distance between the lower edge of the top jacket to a fixed mark on the bottom jacket in order to evaluate collapse. The installation of a steering column (part number) must be performed when measured dimensions (A) fall outside specifications (100 mm).

- Q: What should be checked and replaced with potential steering column damage after an accident on Buick Regal?A:Vehicles sustaining frame damage together with major body damage or sheet metal damage or impact to the Steering Column or deployment of supplemental inflatable restraints systems might develop a damaged or misaligned Steering Column. Verify that the Steering Column bracket capsule components stay firmly in place through the slots while using hand-pressure tests on all components; immediate replacement of bracket assemblies is necessary using new parts when brackets are bolted to jacket structures or jacket assemblies when brackets are welded. Steady the upper jacket at its lower edge and determine the distance to a specified point on the lower jacket to detect jacket collapse; proceed with a new jacket when measurements deviate from standards. Steering Shaft examination must include an assessment for sheared plastic; if sheared plastic appears then install a new Steering Shaft. Any frame damage that might bend the Steering Shaft requires a dial indicator check of the Steering Shaft runout at its lower end during steering wheel rotation. The runout must stay under 1.60 mm.