ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Express 2500 Distributor

Ignition Distributor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Distributors found

Chevrolet Express 2500 Distributor Assembly Part Number: 94672691

$383.36 MSRP: $775.86You Save: $392.50 (51%)Ships in 1-2 Business Days

Chevrolet Express 2500 Distributor Assembly Part Number: 12598210

Chevrolet Express 2500 Distributor

Our website offers an extensive catalog of genuine Chevrolet Express 2500 Distributor at unbeatable prices. Every OEM Chevrolet Express 2500 Distributor comes with a manufacturer's warranty, an easy return policy, and rapid delivery service. Don't miss out on this great opportunity!

Chevrolet Express 2500 Distributor Parts Questions & Experts Answers

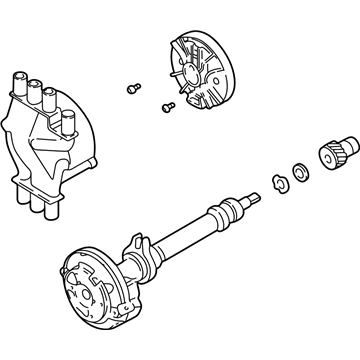

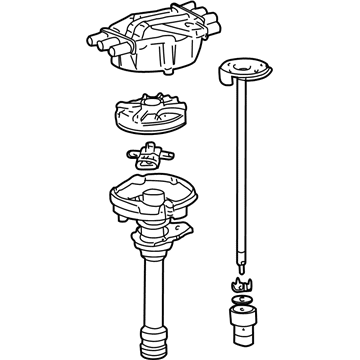

- Q: How to overhaul the distributor on Chevrolet Express 2500?A: Start by removing the engine cover and line up the mark on Distributor bottom stem with the drilled hole in the gear base. Make permanent marks on the Distributor driven gear, Distributor shaft and rotor holes before disassembly because improper reinstallation can cause no-start conditions as well as engine harm. Fit the rotor segment according to v6 specifications ; replace the Distributor when its position does not match specifications. Take out the rotor by removing its two screws and marking down its rotor screw location holes and rotor locator pin while doing so. Remove the two cmp sensor retaining screws before you align the Distributor and vane wheel cutout to the Camshaft Position Sensor position. Then discard these screws. Note the dimple position under the roll pin hole on theardware gear's one side for proper reinstallation. Set the Distributor drive gear inside a v-block while driving out the roll pin using suitable punch tools until you can extract the Distributor shaft with its driven gear along with round washer, tang washer and shim washer for disposal. At assembly time insert the cmp sensor into the housing while correctly positioning its square-cut hole in the vane wheel and secure the sensor using two new screws tightened to 2.2 n.m (20 lb in). Mount the Distributor rotor correctly on the rotor holes before installing it to the index marks. Secure it with two tight hold-down screws adjusted to 1.9 n.m (17 lb in). The Distributor shaft requires the shim washer at its base before adding the tang washer and round washer followed by the application of the driven gear using index marks. Position the rotor segment as shown for v6 motor or v8 motor applications and set the driven gear by making sure the white paint on the Distributor bottom stem matches the pre-drilled hole at the gear base. When the driven gear receives improper installation its dimple will be situated at 180-degree opposition to the rotor segment position. Put the Distributor drive gear into a v-block support structure before adding the roll pin using proper tools to lock the driven gear into place. Install the new oil seal under the Distributor base's mounting flange before reinstalling the Distributor along with the engine cover.