ChevyParts

My Garage

My Account

Cart

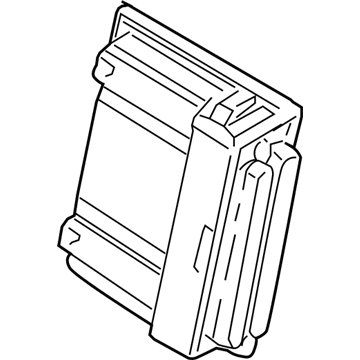

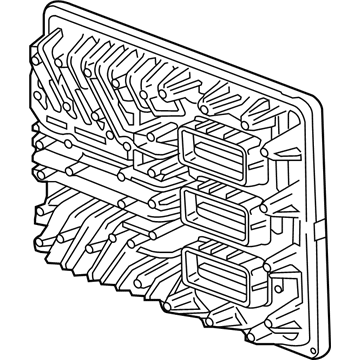

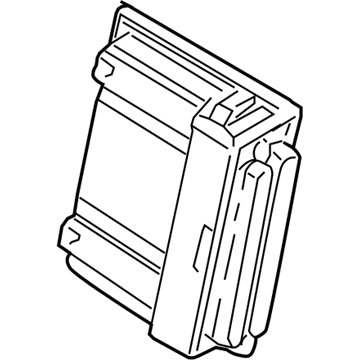

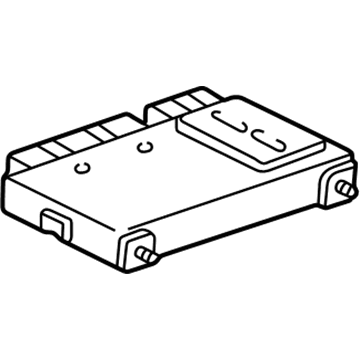

OEM Chevrolet Express 2500 Engine Control Module

Engine Control Computer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Engine Control Modules found

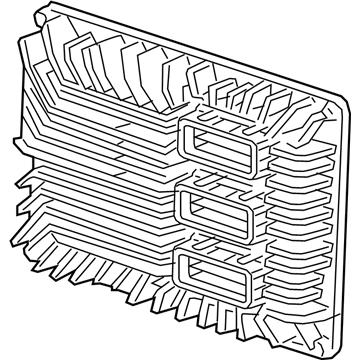

Chevrolet Express 2500 ECM Part Number: 12703872

$204.82 MSRP: $414.92You Save: $210.10 (51%)Ships in 1-3 Business Days

Chevrolet Express 2500 ECM Part Number: 12625455

$232.61 MSRP: $424.70You Save: $192.09 (46%)Ships in 1-2 Business Days

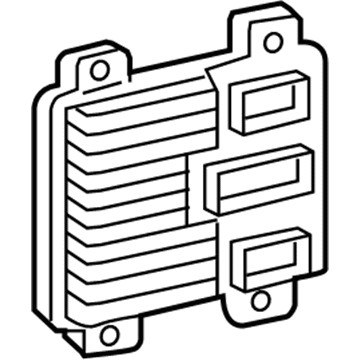

Chevrolet Express 2500 PCM Part Number: 12633238

$245.01 MSRP: $496.56You Save: $251.55 (51%)Ships in 1-2 Business Days

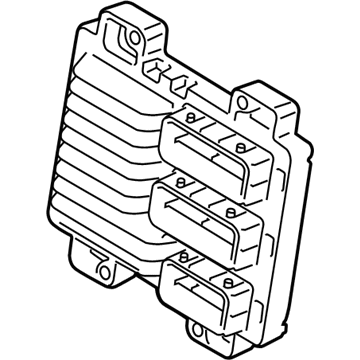

Chevrolet Express 2500 ECM Part Number: 12692200

$186.20 MSRP: $377.12You Save: $190.92 (51%)Ships in 1-2 Business Days

Chevrolet Express 2500 ECM Part Number: 12704475

$240.65 MSRP: $430.72You Save: $190.07 (45%)Ships in 1-3 Business Days

Chevrolet Express 2500 ECM Part Number: 12692201

$151.38 MSRP: $276.36You Save: $124.98 (46%)Ships in 1-2 Business DaysChevrolet Express 2500 ECM Part Number: 12721353

$185.01 MSRP: $331.86You Save: $146.85 (45%)Ships in 1-3 Business DaysChevrolet Express 2500 ECM Part Number: 12721350

$215.44 MSRP: $386.45You Save: $171.01 (45%)Ships in 1-3 Business DaysChevrolet Express 2500 ECM Part Number: 12602801

$534.19 MSRP: $962.30You Save: $428.11 (45%)Ships in 1-2 Business DaysChevrolet Express 2500 PCM Part Number: 12612384

$261.01 MSRP: $488.26You Save: $227.25 (47%)Ships in 1-2 Business DaysChevrolet Express 2500 ECM Part Number: 16216588

$299.95 MSRP: $548.16You Save: $248.21 (46%)Chevrolet Express 2500 PCM Part Number: 12200411

$239.24 MSRP: $434.84You Save: $195.60 (45%)Chevrolet Express 2500 ECM Part Number: 12652526

$1031.92 MSRP: $1834.78You Save: $802.86 (44%)Ships in 1-2 Business DaysChevrolet Express 2500 Control Module Part Number: 9366810

$258.43 MSRP: $470.38You Save: $211.95 (46%)

Chevrolet Express 2500 Control Module Part Number: 16229684

Chevrolet Express 2500 ECM Part Number: 19260753

Chevrolet Express 2500 ECM Part Number: 12648344

Chevrolet Express 2500 ECM Part Number: 19260758

Chevrolet Express 2500 PCM Part Number: 16263494

$341.63 MSRP: $610.42You Save: $268.79 (45%)Chevrolet Express 2500 PCM Part Number: 16244210

| Page 1 of 2 |Next >

1-20 of 23 Results

Chevrolet Express 2500 Engine Control Module

Want to cut long-term maintenance and repair costs? Choose OEM Engine Control Module. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Express 2500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Express 2500 Engine Control Module includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Express 2500 Engine Control Module Parts Questions & Experts Answers

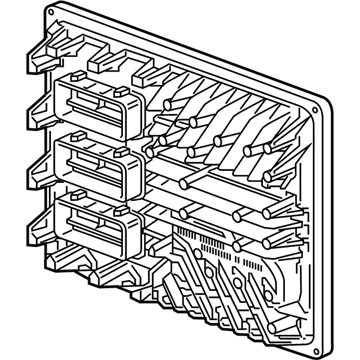

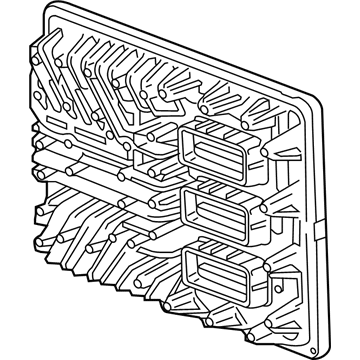

- Q: How to service the Engine Control Module (ECM) on Chevrolet Express 2500?A:Service of the Engine Control Module (ECM) requires a new part interchange or eeprom programming. Verify that the new ecm matches the requirements before you remove the faulty ecm to install the service ecm model. Power losses must be implemented through a complete ignition shut-off during the handling of control module connectors as well as power disconnect and reconnect operations to shield internal module damage. Keeping the metal case of the control module away from battery voltage ensures its protection from damage. Electrostatic discharge damage can be prevented by avoiding touch of connector pins or circuit board soldered components and cleaning all control module connector surfaces. Check that control module connector gaskets are properly installed to block contaminates from entering the module area. A replacement control module requires programming and recording engine oil life remains or else the system will set the oil to be changed at 5,000 km (3,000 mi) from the last change. Operating a scan tool enables you to retrieve the remaining engine oil life percentage which should then be documented. Disconnect the negative Battery Cable as well as the engine wiring harness electrical connectors which belong to the ecm. To detach the ecm from the bracket the user needs to release tabs on the ecm bracket. To install the system position the ecm into its bracket so the ecm bracket tabs can completely connect. Reestablish the connection between the ecm and engine wiring harness electric connectors and the negative Battery Cable. New ecm installation requires ecm programming followed by the use of a scan tool for setting the engine oil life.