ChevyParts

My Garage

My Account

Cart

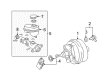

OEM Chevrolet Monte Carlo Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Brake Boosters found

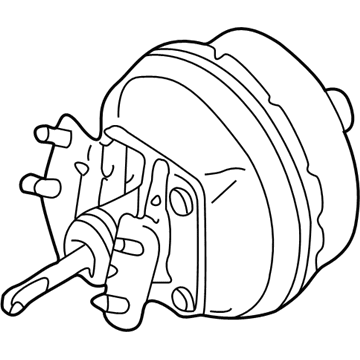

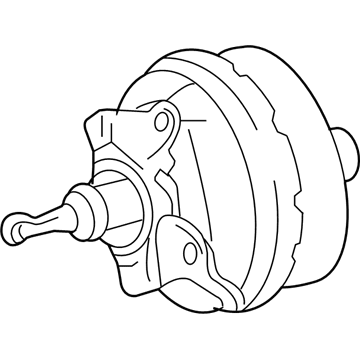

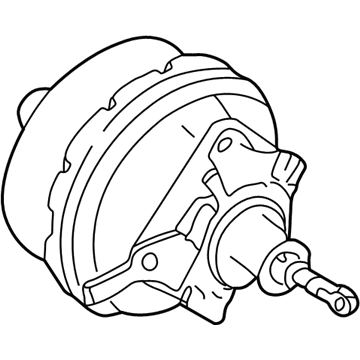

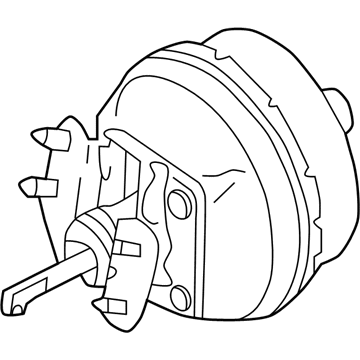

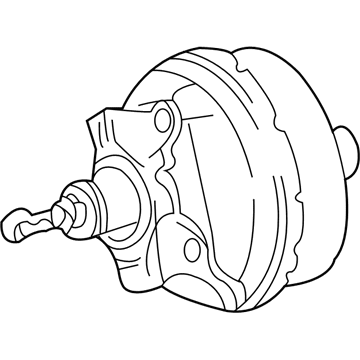

Chevrolet Monte Carlo Brake Booster Part Number: 88967269

Chevrolet Monte Carlo Brake Booster Part Number: 15806655

Chevrolet Monte Carlo Brake Booster Part Number: 88967260

Chevrolet Monte Carlo Brake Booster Part Number: 18060109

Chevrolet Monte Carlo Brake Booster Part Number: 15236237

Chevrolet Monte Carlo Brake Booster Part Number: 88967239

Chevrolet Monte Carlo Brake Booster Part Number: 25511548

Chevrolet Monte Carlo Brake Booster Part Number: 19208172

Chevrolet Monte Carlo Brake Booster Part Number: 18043590

Chevrolet Monte Carlo Brake Booster

Want to cut long-term maintenance and repair costs? Choose OEM Brake Booster. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Monte Carlo parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Monte Carlo Brake Booster includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Monte Carlo Brake Booster is an essential part that decreases the force required to apply the brake of the car. The brake booster makes use of vacuum chamber that increases the hydraulic pressure that is coming from the master cylinder, thus increasing the force that a driver uses when applying the break pedal. There are two main types of boosters used in Monte Carlo vehicles: hence the vacuum-operated boosters and hydraulic boosters. Vacuum boosters depend on the difference in pressure of the engine vacuum and the atmospheric pressure as the source of power while hydraulic boosters employ fluid pressure in order to exert force in the application of the brake. These boosters are normally dependable and use but can at times tend to go out and this may warrant replacement. Further, performance brake boosters and power brake conversion kits are other popular parts you can get in case you desire to employ better and more effective brake systems.

Chevrolet Monte Carlo Brake Booster Parts and Q&A

- Q: How to replace the vacuum brake booster on a 3.4L engine on Chevrolet Monte Carlo?A:To fix the Brake Booster on a 3.4l engine you need the power Brake Booster holder item j 22805-b. Start by taking off the negative Battery Cable then removing the insulator on the left instrument panel. Unplug the stop lamp switch from its electrical connection while removing the clip attached to its Brake Booster hook. This disconnects the Brake Pedal(animation rod). Cut some cooling fluid before taking off the cross vehicle brace and air cleaner inlet duct. Begin fuel system decompression then uninstall all ducts related to the evap canister purge valve and fuel system feeds while setting them off to the side. Sever the bypass tubes of the coolant outlet and inlet lines before you take the heater inlet hose off. Move the engine forward and then take off the power brake level sensor's electrical connector. Do not remove the brake pipes at the master cylinder end; keep them in place and disconnect the master cylinder by its two retaining nuts. To work on the Brake Booster remove the vacuum check valve only when you keep the combined vacuum hose and check valve as one piece. Fit the power Brake Booster holder (J 22805-B) to the booster through master cylinder retaining nuts then release the cowl lock to rotate the booster counterclockwise using a ratchet and flat-bladed tool alongside depressor of the Brake Booster locking tab. Take out the vacuum Brake Booster and remove its attaching piece called the power Brake Booster holder part number j 22805-b. Install the booster by keeping its internal parts original and undamaged locking flanges. Place the vacuum Brake Booster on the cowl and turn it counterclockwise until the locking flanges engage. Afterward, use a ratchet on the power Brake Booster holder (J 22805-B) to rotate the booster clockwise which locks the tab. Install the vacuum hose with check valve when you take out the power Brake Booster holder (J 22805-B). Put the master cylinder back on top of the booster unit and fasten its retaining nuts with a torque of 33 nm (24 ft. Lbs.). Set the brake fluid sensor electrical connection while placing the engine back in its regular position and fastening the engine mount struts on both sides. Put back the heater inlet pipe and join the coolant outlet and inlet bypass tubes while attaching the evap canister purge valve, fuel feed and return pipes. Complete the work by putting back the air cleaner inlet, crossing brace, filling the cooling system, connecting the pushrod to the Brake Pedal, attaching the clip, joining the stop lamp electrical connector, installing the instrument panel insulator, and linking the battery negative cable.