ChevyParts

My Garage

My Account

Cart

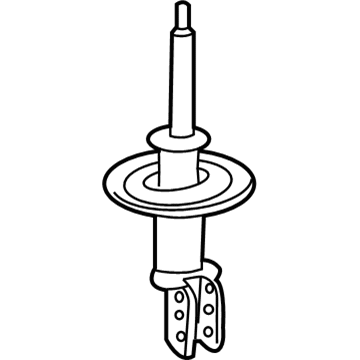

OEM Chevrolet Monte Carlo Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Shock Absorbers found

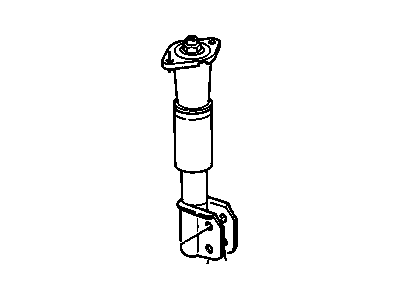

Chevrolet Monte Carlo Strut Part Number: 88965467

$109.69 MSRP: $212.92You Save: $103.23 (49%)Chevrolet Monte Carlo Shock Absorber Part Number: 88945170

$43.58 MSRP: $77.83You Save: $34.25 (45%)Ships in 1-3 Business Days

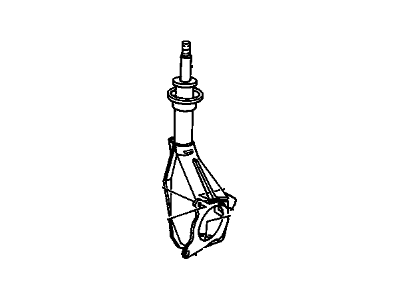

Chevrolet Monte Carlo Strut, Rear Part Number: 22064760

Chevrolet Monte Carlo Strut Cartridge, Front Part Number: 22074850

Chevrolet Monte Carlo Strut, Rear Part Number: 22064714

Chevrolet Monte Carlo Strut, Rear Part Number: 22064554

Chevrolet Monte Carlo Strut Part Number: 88965469

Chevrolet Monte Carlo Strut Part Number: 88965468

Chevrolet Monte Carlo Strut, Rear Part Number: 22064558

Chevrolet Monte Carlo Shock Absorber Part Number: 88945324

$57.13 MSRP: $102.02You Save: $44.89 (44%)

Chevrolet Monte Carlo Shock Absorber

Want to cut long-term maintenance and repair costs? Choose OEM Shock Absorber. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Monte Carlo parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Monte Carlo Shock Absorber includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

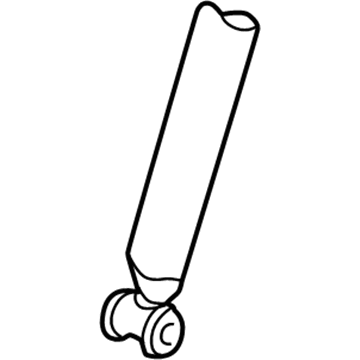

The likewise extremely important Shock Absorber of Chevrolet Monte Carlo vehicles is a component of the suspension system that functions together with the struts. This is because the Shock Absorber causes the dissipation of Kinetic Energy into heat hence minimizing the instances of bouncing and vibrations that compromise handling and on car stability. Different Models of Monte Carlo vehicles have used the following Shock Absorbers; Twin Tube and Mono Tube Shock absorbers which have different processes of regulating the flow of hydraulic fluid and offering improved suspension depending on the style of the drive. Other developments such as PSD and ASD go deeper into the Shock Absorber's responses and new technologies like electrorheological and magnetorheological dampers make suspension systems semi-active and adaptive to achieve added comfort and control.

Chevrolet Monte Carlo Shock Absorber Parts and Q&A

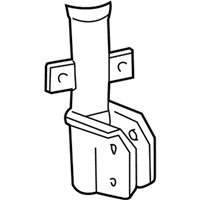

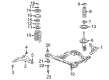

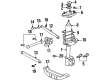

- Q: How to service and repair the front coil springs and shock absorber on Chevrolet Monte Carlo?A:In order to service and repair the suspension strut, it begins with removing the strut from the vehicle. Subsequently, install the strut in the strut spring compressor (J 45400). It is necessary also to ensure the spring is compressed when the strut moves freely. Depress the spring compressor forcing screw so as to compress the coil spring. Locate with a 45 torx socket the strut shaft and detach the upper strut mount nut with the strut rod nut socket (J 42991). After pulling the strut out using the strut spring compressor (J 45400), loosen the forcing screw while compressor until the upper strut mount and coil spring will come out. Go ahead and reinstall the coil spring and upper strut mount back to the strut spring compressor (J 45400) and compress the coil spring further by turning the spring compressor forcing screw. Mount the strut to the coil spring and to the top strut mount, topping it with the strut retaining nut. By tightening the strut rod nut socket (J 42991) and using a 45 torx socket, tighten the strut mount nut to 70 n.m (52 ft. Lbs.). Finally, lift up the strut from the strut spring compressor (J 45400) and replace it back to the vehicle.

- Q: How to replace the front shock absorber assembly on Chevrolet Monte Carlo?A:Start by taking off the upper nuts from the strut assembly. Raise the vehicle by using ONLY a frame-contact vehicle lift which must avoid suspension-contact vehicle lift systems. After vehicle support and strut elevation use a marker to draw lines on the knuckle from where the strut connects. Start by removing the lower bolts and nuts from the strut followed by the strut assembly removal process. Initiate strut installation by following the Fastener Notice in Service Precautions while installing the component. Tighten the strut upper nuts until they reach 33 Nm torque (24 ft. lbs.) measurements. Strut lower bolts and nuts need installation as prevailing torque type fasteners that can be re-used only if the fasteners and counterparts are rust-free and clean and produce 3 Nm (27 inch lbs.) of torque against their counterpart before fully seating. otherwise, replace the fastener. Tighten the lower nuts of the strut to 122 Nm (90 ft. lbs.) while aligning its position with the knuckle mark. Finish by placing the tire and wheel on the vehicle while lowering it to the ground for front wheel alignment.