ChevyParts

My Garage

My Account

Cart

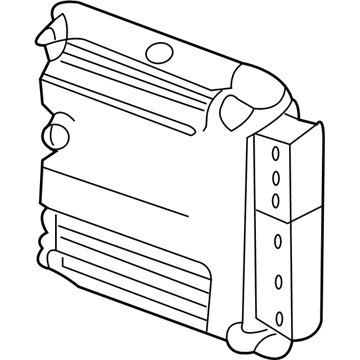

OEM Chevrolet Silverado 3500 Engine Control Module

Engine Control Computer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Engine Control Modules found

Chevrolet Silverado 3500 ECM Part Number: 15292913

$1098.11 MSRP: $1808.92You Save: $710.81 (40%)Ships in 1-2 Business DaysChevrolet Silverado 3500 PCM Part Number: 12583560

$271.45 MSRP: $498.32You Save: $226.87 (46%)Chevrolet Silverado 3500 PCM Part Number: 19299227

$240.92 MSRP: $441.84You Save: $200.92 (46%)Ships in 1-2 Business DaysChevrolet Silverado 3500 PCM Part Number: 12200411

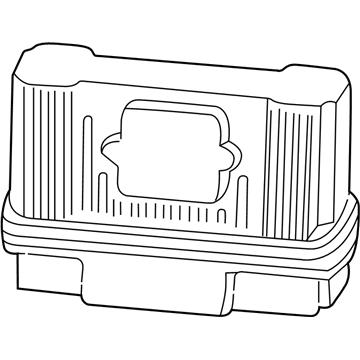

$239.24 MSRP: $434.84You Save: $195.60 (45%)Chevrolet Silverado 3500 ECM Part Number: 12602801

$534.19 MSRP: $962.30You Save: $428.11 (45%)Ships in 1-2 Business Days

Chevrolet Silverado 3500 ECM Part Number: 19260753

Chevrolet Silverado 3500 ECM Part Number: 97780075

Chevrolet Silverado 3500 PCM Part Number: 12581565

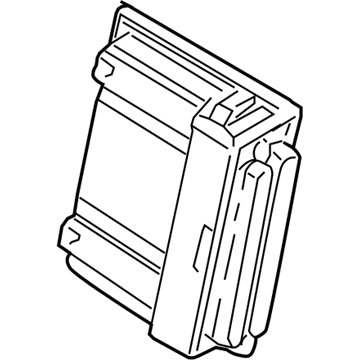

Chevrolet Silverado 3500 Engine Control Module

Want to cut long-term maintenance and repair costs? Choose OEM Engine Control Module. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Silverado 3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Silverado 3500 Engine Control Module includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Silverado 3500 Engine Control Module Parts Questions & Experts Answers

- Q: How to replace the Engine Control Module safely and effectively on Chevrolet Silverado 3500?A:A powered-up ignition should always be switched off before beginning to work on the powertrain control module (PCM). This ensures the pcm remains undamaged during power disconnection or reconnection. Remove all debris from around pcm connector surfaces before checking the installation of pcm module connector gaskets to avoid contaminant access. A scan tool allows you to retrieve engine oil life percentages which must be recorded before the replacement module installation because not programming this data will trigger a 100% default that requires an oil change within 5000 km (3,000 mi) of the last change. To begin the procedure disconnect the negative Battery Cable along with removing the harness ground clip from pcm cover when rpo nos exists. The hybrid control module (HCM) needs removal when dealing with vehicles equipped with rpo hp2. Unfasten the pcm cover mounting tabs and detach the pcm cover from its place. When disabling the electrical connectors from the pcm use care not to allow the ignition to be on while working because this could harm components. Disengage the spring latch and mounting tabs attached to the pcm before extracting the pcm from its place. The installation process requires you to enter the mounting tabs and fasten the spring latch onto the new pcm. After attaching the pcm electrical connectors install the bolts just to 8 n.m (71 lb in). Install the pcm cover along with reattaching the hcm when your vehicle has rpo hp2 and continue if your vehicle lacks this reference. Users of rpo nys should connect the harness ground clip to the pcm cover and reinstall the negative Battery Cable before pcm programming if needed.