ChevyParts

My Garage

My Account

Cart

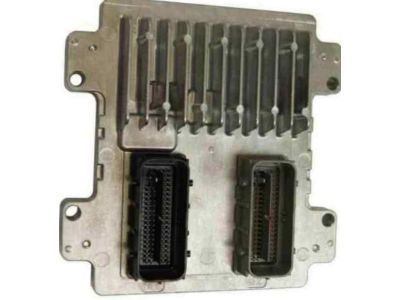

OEM GMC Savana 1500 Engine Control Module

Engine Control Computer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Engine Control Modules found

GMC Savana 1500 Knock Sensor Part Number: 12612397

$316.33 MSRP: $642.48You Save: $326.15 (51%)

GMC Savana 1500 ECM Part Number: 12635043

$213.69 MSRP: $434.02You Save: $220.33 (51%)Ships in 1-2 Business Days

GMC Savana 1500 PCM Part Number: 12633238

$245.01 MSRP: $496.56You Save: $251.55 (51%)Ships in 1-2 Business Days

GMC Savana 1500 ECM Part Number: 12625455

$232.61 MSRP: $424.70You Save: $192.09 (46%)Ships in 1-2 Business DaysGMC Savana 1500 Control Module Part Number: 9366810

$258.43 MSRP: $470.38You Save: $211.95 (46%)GMC Savana 1500 PCM Part Number: 12612384

$261.01 MSRP: $488.26You Save: $227.25 (47%)Ships in 1-2 Business DaysGMC Savana 1500 ECM Part Number: 12602801

$534.19 MSRP: $962.30You Save: $428.11 (45%)Ships in 1-2 Business Days

GMC Savana 1500 Control Module Part Number: 16229684

GMC Savana 1500 PCM Part Number: 16244210

GMC Savana 1500 PCM Part Number: 12581565

GMC Savana 1500 PCM Part Number: 16263494

$341.63 MSRP: $610.42You Save: $268.79 (45%)

GMC Savana 1500 Engine Control Module

Want to cut long-term maintenance and repair costs? Choose OEM Engine Control Module. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Savana 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Savana 1500 Engine Control Module includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

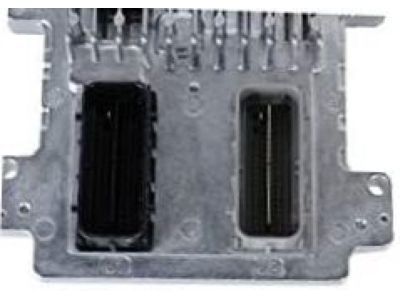

GMC Savana 1500 Engine Control Module Parts Questions & Experts Answers

- Q: How to service the Engine Control Module (ECM) on GMC Savana 1500?A:Engine Control Module service requires ecm replacement and eeprom programming as one solution. The correct replacement ecm needs to be verified before removing the malfunctions ecm and placing the new service ecm into position. Turn off the ignition completely before working with connectors and dis/connecting power to avoid equipment breakdown inside the units. The metal case of control modules should stay away from battery voltage and you should not handle the pin connectors or solder joints to avoid electrostatic discharge damage. Check the control module connector area for debris before looking for proper gasket installation to block contaminant entry. Any update software process on the new control module should include recording engine oil life metrics because this omission sets default engine oil requirements to 100 percent which requires an oil change at 5000 km (3,000 mi) after the previous change. The percentage of engine oil remaining life must be retrieved using a scan tool followed by recording it. First disconnect the negative Battery Cable while you disconnect all engine wiring harness electrical connectors from the ecm. Pull away the tabs which secure the ecm bracket before taking out the ecm from its positioning. Position the ecm into its bracket before securing it by letting the bracket tabs reach inside the unit then secure the engine wiring harness connectors. After reconnecting the negative Battery Cable, program any new ecms according to the necessary procedures. A scan tool can be used for determining and setting the engine oil lifetime.