ChevyParts

My Garage

My Account

Cart

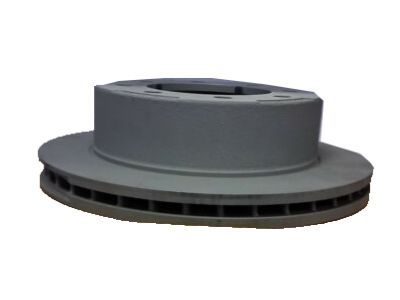

OEM GMC Savana 2500 Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Brake Discs found

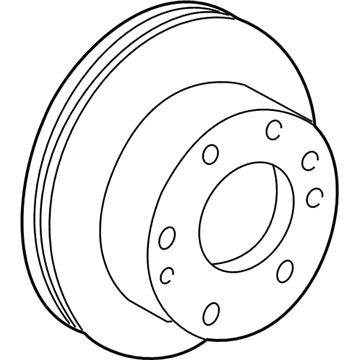

GMC Savana 2500 Rotor Part Number: 15712803

$170.40 MSRP: $325.78You Save: $155.38 (48%)Ships in 1-2 Business Days

GMC Savana 2500 Rotor Part Number: 15712801

$96.36 MSRP: $180.93You Save: $84.57 (47%)

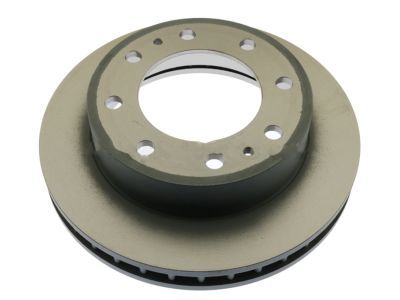

GMC Savana 2500 Rotor, Front Part Number: 22950036

$131.59 MSRP: $257.65You Save: $126.06 (49%)Ships in 1-3 Business Days

GMC Savana 2500 Rotor, Front Part Number: 19210603

$94.27 MSRP: $182.96You Save: $88.69 (49%)Ships in 1-2 Business Days

GMC Savana 2500 Rotor, Front Part Number: 15942198

$192.78 MSRP: $374.16You Save: $181.38 (49%)Ships in 1-2 Business Days

GMC Savana 2500 Rotor, Front Part Number: 15942195

$154.61 MSRP: $302.70You Save: $148.09 (49%)Ships in 1-2 Business Days

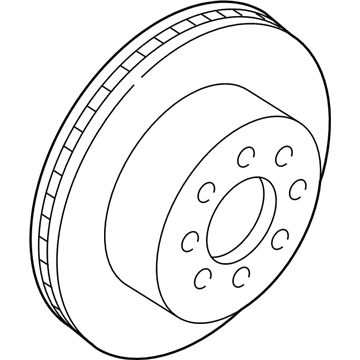

GMC Savana 2500 Rotor, Rear Part Number: 15127537

$134.88 MSRP: $264.04You Save: $129.16 (49%)Ships in 1-2 Business Days

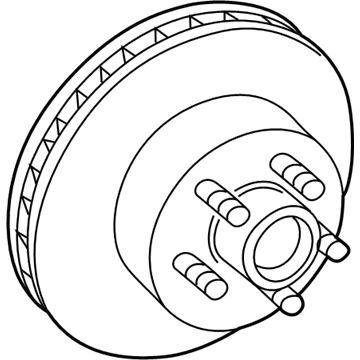

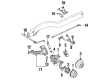

GMC Savana 2500 Hub & Rotor, Front Part Number: 19202727

GMC Savana 2500 Hub & Rotor, Front Part Number: 19152696

GMC Savana 2500 Rotor, Rear Part Number: 15749909

GMC Savana 2500 Brake Disc

Want to cut long-term maintenance and repair costs? Choose OEM Brake Disc. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Savana 2500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Savana 2500 Brake Disc includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Savana 2500 Brake Disc Parts and Q&A

- Q: How to replace the front brake disc (JH5) on GMC Savana 2500?A:Start Brake Disc jh5 replacement by checking the brake master cylinder reservoir fluid level. Drain fluid to the middle point if reservoir liquid is above that mark. Lift the vehicle moderately then take off the wheel and tire parts. Keep a reference point when reinstalling the original Brake Disc because it must align with the Wheel Hub properly. Put down 2 large c-clamps onto caliper housing and push them against disc housing to draw all brake pistons into their home position. Secure the brake caliper with mechanic wire to protect the hydraulic brake hose during maintenance. Securely suspend the brake caliper assembly by removing its 2 bolts then placing wire under it during the removal process. To access the wheel studs remove Brake Disc retaining push nuts if needed and separate the Brake Disc screw. First place wheel nuts on the studs then hit between the studs for a perfect disc removal with a deadblow hammer. After cleaning all surfaces apply penetrating oil then add two m10 x 1.5 bolts in disc's threaded holes with regular tightening to push the disc away. To install the part use the j-42450-a (Wheel Hub Resurfacing Kit) to clean rust from the hub flange and use j-41013 (Disc Resurfacing Kit) to clean the inner Brake Disc surface. Apply the disc to its original position while monitoring that no particles reach the surfaces and install it. Secure the Brake Disc screw at 12 nm (106 lb in), put in the brake caliper and bracket. Prepare the mounting bolt threads by clearing away residual adhesive then using brake parts cleaner to clean the threads. Finish the preparation by applying threadlocker gm p/n 12345493 (Canadian P/N 10953488) onto the threads. Put on the two mounting bolts and secure them to 175 nm torque value. Put back the tire and wheel components before gently pushing the brake pedal to its middle range through several activation cycles until a solid braking effect exists. Add fresh brake fluid to the reservoir until it reaches the correct mark. The braking system needs to be run in with new Brake Pads against refreshed or new discs.

- Q: What Tools Are Required to Refinish a Brake Disc and What Steps Should Be Followed on GMC Savana 2500?A:In order to refinish a brake disc, the following tools are required: Rotor Resurfacing Kit ( J41013 ) and Wheel Hub Resurfacing Kit ( J42450-A ). Before beginning, make sure that the disc has enough thickness to stay above the minimum specification allotted after refinishing is done. Refinement is warranted only if the thickness variation is greater than that for maximum allowable specification, if there is too much corrosion or pitting, cracks and heat spots, abnormality in blueing discoloration, or scoring beyond the maximum allowable specification. Start by cleaning any rust or corrosion of the hub/axle flange mating surface with the Wheel Hub Resurfacing Kit (J42450-A) and then use Rotor Resurfacing Kit (J41013) to clean the brake disc mating and mounting surfaces. Examine both surfaces and remove any foreign particles or debris and then, mount the brake disc to the brake lathe, following manufacturer guidelines that all attachments in the lathe are clean. When the lathe is running - bring in the cutting tools till the tool touches the disc friction surfaces - check the witness mark; It will be necessary to remount the disc if it does not extend three-quarters of it around the disc. Refinish the disc by following the lathe manufacturer's instructions and checking the thickness after every cut. In case the disc turns out to be above the minimum allowable thickness after refinishing, it has to be replaced. In order to obtain a non-directional finish, follow the instructed speed settings and apply the finish with a non-directional finishing tool and 120 grit aluminum oxide sandpaper or sand block with 150 grit aluminum oxide sandpaper. After this, clean the friction surfaces with denatured alcohol or an approved brake cleaner, take disc from the lathe; evaluate the assembled LRO to guarantee optimal performance of disc brakes and modify if needed.