ChevyParts

My Garage

My Account

Cart

OEM GMC Yukon XL 1500 CV Joint

CV Joint Axle- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 CV Joints found

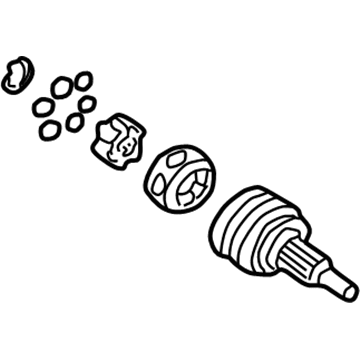

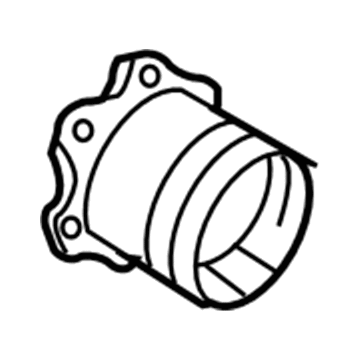

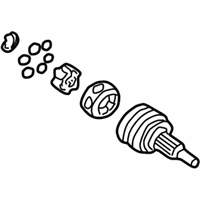

GMC Yukon XL 1500 C.V. Joint, Front Part Number: 26058362

$249.99 MSRP: $405.72You Save: $155.73 (39%)GMC Yukon XL 1500 Inner CV Joint, Front Part Number: 84814583

$80.05 MSRP: $125.40You Save: $45.35 (37%)Ships in 1-3 Business DaysGMC Yukon XL 1500 C.V. Joint, Front Part Number: 22928970

$135.51 MSRP: $215.15You Save: $79.64 (38%)Ships in 1-2 Business DaysGMC Yukon XL 1500 Inner CV Joint, Front Part Number: 26062617

GMC Yukon XL 1500 Inner CV Joint, Front Part Number: 15295246

GMC Yukon XL 1500 CV Joint

Want to cut long-term maintenance and repair costs? Choose OEM CV Joint. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Yukon XL 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Yukon XL 1500 CV Joint includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Yukon XL 1500 CV Joint Parts Questions & Experts Answers

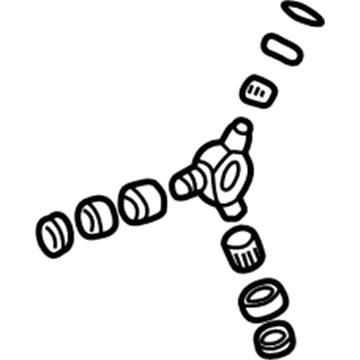

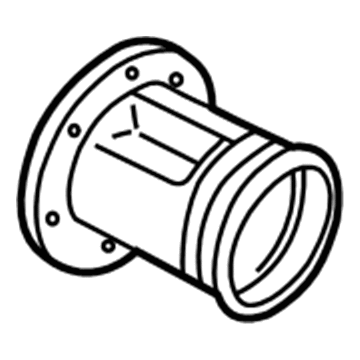

- Q: How to replace the CV Joint and seal on the wheel drive shaft inner on GMC Yukon XL 1500?A:Affect an inner joint and seal on the wheel drive shaft without tools using the following items; snap ring pliers (J 8059), seal clamp tool (J 35910), split plate swage clamp for k1 5 models (J 36652-98), and split plate swage clamp for k25 models (J 36652-1). Start by cutting through the swage ring and undoing the tri-pot housing from the halfshaft without doing any harm to the latter part. Tidy the tri-pot assembly roller bearings and housing, by degreasing it completely and leaving it to dry off. The spider tri-pot may also be delicate to handle to avoid tri-pot balls and needle rollers separation. Cut out the small seal clamp using side cutters and squeeze the tri-pot seal up the halfshaft. Use the snap ring pliers to spread the spider spacer ring then pull out the spacer ring, spider assembly, and tri-pot seal of the halfshaft bar. Brush the halfshaft bar with a wire brush checking every component for use and damage. For assembly, install the new small seal clamp on the joint seal by depressing the same onto the halfshaft bar and fasten with the seal clamp tool tightening to 136 nm (100 ft. Lbs.). Mount the convolute retainer and tri-pot spider assembly and then the spacer ring. Pack the tri-pot seal and housing with the given grease, and then reassemble with the swage ring. Mount split plate swage clamp in a vise, under the correct model tool, and verify the inboard stoke position. Align and do the tightness of the swage ring and pump, taking care that all of the components aligned well before constituent final assembly. Lastly, take out the halfshaft assembly from the tool and the convolute retainer from the seal.