ChevyParts

My Garage

My Account

Cart

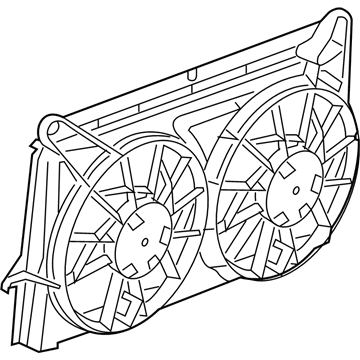

OEM GMC Yukon XL 1500 Fan Shroud

Radiator Fan Shroud- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Fan Shrouds found

GMC Yukon XL 1500 Fan Shroud Part Number: 15780789

$224.71 MSRP: $424.99You Save: $200.28 (48%)Ships in 1-2 Business DaysGMC Yukon XL 1500 Fan Shroud Part Number: 15780788

$185.27 MSRP: $350.41You Save: $165.14 (48%)Ships in 1-3 Business Days

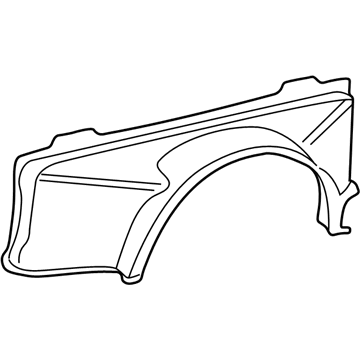

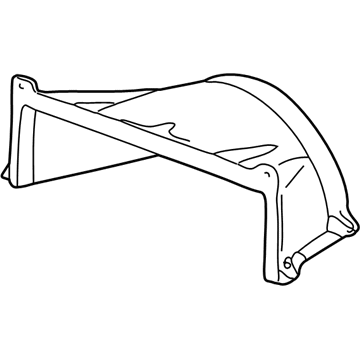

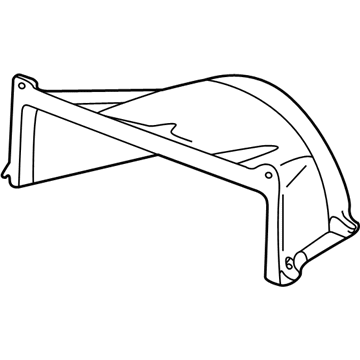

GMC Yukon XL 1500 Upper Shroud Part Number: 15088328

$77.77 MSRP: $121.82You Save: $44.05 (37%)

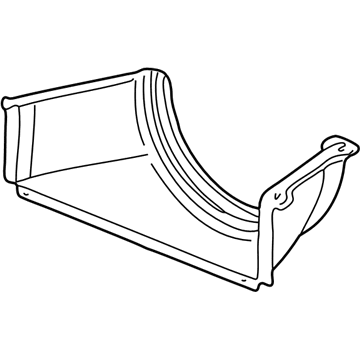

GMC Yukon XL 1500 Fan Shroud, Lower Part Number: 15267487

$4.59 MSRP: $7.19You Save: $2.60 (37%)GMC Yukon XL 1500 Fan Shroud, Lower Part Number: 15846374

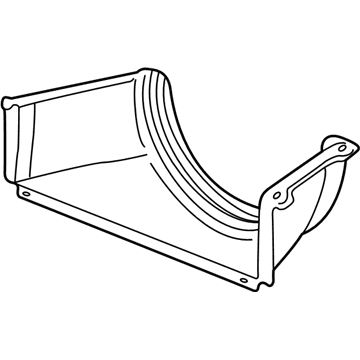

GMC Yukon XL 1500 Lower Shroud Part Number: 15707562

GMC Yukon XL 1500 Fan Shroud Part Number: 15215187

GMC Yukon XL 1500 Upper Shroud Part Number: 15088327

GMC Yukon XL 1500 Fan Shroud

Want to cut long-term maintenance and repair costs? Choose OEM Fan Shroud. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Yukon XL 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Yukon XL 1500 Fan Shroud includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Yukon XL 1500 Fan Shroud Parts Questions & Experts Answers

- Q: How to replace the upper fan shroud on GMC Yukon XL 1500?A:The first step in replacing the upper Fan Shroud involves loosening the clamps on the air cleaner outlet duct at the Throttle Body and maf/iat sensor of vehicles with 4.31l, 4.8l, 5.3l or 6.0l engines. Next, remove the air cleaner outlet duct. Losing the clamps on the 8.1l engine duct requires the same process as the other engines before duct removal. The procedure to replace the upper Fan Shroud starts by removing the engine harness clip on the pcm cover and tcm cover bolts followed by lifting the tcm cover to unclip it from the Fan Shroud of vehicles with 6.0l, 6.6l or 8.1l engines equipped with rpo m74 transmission. Disconnect the tcm electrical connectors and take out the tcm unit together with its cover. Before taking out the inlet hose from the Radiator the 4.81l 5.3l or 6.0l engine needs its inlet hose clamp repositioned at the Radiator and its rosebud clips at the Fan Shroud and air cleaner outlet duct removed. Before removing the upper Fan Shroud the technician must first detach the Fan Shroud retainers and bolts. Begin with inserting the upper Fan Shroud into its correct placement, then install Fan Shroud bolts and tighten them to 9 nm (80 inch lbs.) before installing the Fan Shroud retainers. Place the inlet hose on the Radiator while installing the clamp for engines using 4.81l, 5.3l or 6.0l power units. Put the inlet hose rosebud clips on both the Fan Shroud and the air cleaner outlet duct. Reinstallation of the tcm electrical connectors should occur before installing the tcm with its cover. Install the tcm electrical connector bolts to 8 nm (71 inch lbs.) while installing the tcm cover bolts to 9 nm (80 inch lbs.). You should install the air cleaner outlet duct on vehicles with 8.1l engines by using clamps on the Throttle Body and maf/iat sensor to achieve 7 nm of torque (62 inch lbs.). When installing the air cleaner outlet duct on the 4.3l engine keep the hinge clip matched to the Throttle Body lip before lowering the duct until the mounting stud passes through the hole. Complete this step by installing the wingnut to a torque of 3 nm (27 inch lbs.) along with tightening the clamps at the Throttle Body and maf/iat sensor to 7 nm (62 inch lbs.).