ChevyParts

My Garage

My Account

Cart

OEM Buick Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

58 Flywheels found

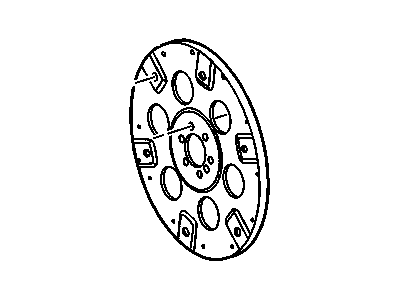

Buick Drive Plate Part Number: 12576272

$75.24 MSRP: $103.00You Save: $27.76 (27%)Product Specifications- Other Name: Plate, Automatic Transmission Flexible; Plate, Engine Crankshaft

- Replaces: 24100152

Buick Drive Plate Part Number: 12689672

$23.89 MSRP: $37.41You Save: $13.52 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Plate, Engine Crankshaft

Buick Flywheel Part Number: 55577722

$108.76 MSRP: $170.37You Save: $61.61 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Flywheel, Engine Crankshaft

Buick Drive Plate Part Number: 12686891

$48.41 MSRP: $75.83You Save: $27.42 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Plate, Engine Crankshaft

- Replaces: 12655475

Buick Drive Plate Part Number: 471529

$140.65 MSRP: $166.69You Save: $26.04 (16%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel; Flywheel, Engine Crankshaft

Buick Flywheel Part Number: 55574137

$318.37 MSRP: $500.72You Save: $182.35 (37%)Product Specifications- Other Name: Flywheel, Engine Crankshaft

- Replaces: 55562132

Buick Drive Plate Part Number: 12572042

Product Specifications- Other Name: Plate, Engine Crankshaft

Buick Drive Plate Part Number: 12609155

$52.46 MSRP: $82.19You Save: $29.73 (37%)Product Specifications- Other Name: Flywheel, Engine Crankshaft; Flywheel

- Replaces: 24508110, 24505212

Buick Drive Plate Part Number: 12568922

Product Specifications- Other Name: Plate Assembly-Automatic Transmission Flexible; Plate, Engine Crankshaft

Buick Flywheel Part Number: 10044408

Product Specifications- Other Name: Flywheel, Engine Crankshaft

Buick Drive Plate Part Number: 22520094

Product Specifications- Other Name: Disk; Flywheel, Engine Crankshaft

Buick Drive Plate Part Number: 25512349

Product Specifications- Other Name: Flywheel

Buick Drive Plate Part Number: 12582608

Product Specifications- Other Name: Flywheel, Engine Crankshaft

Buick Drive Plate Part Number: 12609154

Product Specifications- Other Name: Flywheel, Engine Crankshaft; Flywheel

- Replaces: 24506809

Buick Drive Plate Part Number: 10018740

Product Specifications- Other Name: Flywheel; Flywheel, Engine Crankshaft

Buick Drive Plate Part Number: 14085471

Product Specifications- Other Name: Flywheel; Flywheel, Engine Crankshaft

Buick Drive Plate Part Number: 25517709

Product Specifications- Other Name: Flywheel, Engine Crankshaft

Buick Drive Plate Part Number: 25535388

Product Specifications- Other Name: Flywheel, Engine Crankshaft

Buick Drive Plate Part Number: 25523510

Product Specifications- Other Name: Flywheel, Engine Crankshaft

Buick Drive Plate Part Number: 25515222

Product Specifications- Other Name: Flywheel, Engine Crankshaft

| Page 1 of 3 |Next >

1-20 of 58 Results

Buick Flywheel

Choose OEM Flywheel, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Buick's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsGiant.com, you'll find it easy to get top-quality OEM Buick Flywheel. You can shop at highly competitive prices and protect your budget. All our genuine Buick parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Buick Flywheel Parts and Q&A

- Q: How to perform a flywheel replacement procedure on Buick Enclave?A:To remove the engine Flywheel, one has to remove the transmission in both all wheel drive and front wheel drive configurations first. Secondly, remove the engine Flywheel bolts and the Flywheel. Clean and examine the Flywheel closely; if any teethes are damaged, inspect Starter for correct operation, and replace it if excessive wear or damage to Starter Drive exists. Inspect and mount the engine Flywheel, bolt it and then reinstall the transmission.

- Q: How to replace the engine flywheel on Buick Regal?A:A technician needs to start the Flywheel replacement process by removing the transaxle. The Flywheel holder (J 37096) must be used to stop Crankshaft rotation before beginning the process of unfastening the eight engine Flywheel bolts. Keep one of the eight Crankshaft bolts in its place which is located at the Crankshaft's top rotation position. Hold the engine Flywheel tightly before unscrewing the last bolt while keeping the Flywheel from falling. You can install the new engine Flywheel with help from the Flywheel holder (J 37096) which continuously prevents Crankshaft rotation. Fasten the new engine Flywheel bolts with a torque of 15 nm (11 ft. Lbs.). The electronic torque angle meter (J 36660-A) enables you to properly rotate the engine Flywheel bolts another 50 degrees. A dial indicator mounted on the engine block should determine engine Flywheel runout at the three attachment bosses; a new engine Flywheel should replace the current one if any condition cannot be remedied. Finally, reinstall the transaxle.