ChevyParts

My Garage

My Account

Cart

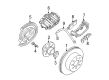

OEM Chevrolet Avalanche 1500 Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Brake Discs found

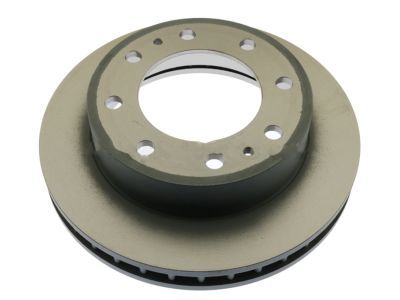

Chevrolet Avalanche 1500 Brake Rotor Part Number: 25757802

$143.40 MSRP: $274.21You Save: $130.81 (48%)Ships in 1-2 Business Days

Chevrolet Avalanche 1500 Rotor Part Number: 15712801

$96.36 MSRP: $180.93You Save: $84.57 (47%)

Chevrolet Avalanche 1500 Rotor, Front Part Number: 22950036

$131.59 MSRP: $257.65You Save: $126.06 (49%)Ships in 1-3 Business Days

Chevrolet Avalanche 1500 Rotor, Front Part Number: 19210603

$94.27 MSRP: $182.96You Save: $88.69 (49%)Ships in 1-2 Business Days

Chevrolet Avalanche 1500 Rotor, Front Part Number: 15942195

$154.61 MSRP: $302.70You Save: $148.09 (49%)Ships in 1-2 Business Days

Chevrolet Avalanche 1500 Rotor Part Number: 19211496

Chevrolet Avalanche 1500 Rotor Part Number: 26088273

Chevrolet Avalanche 1500 Brake Disc

Want to cut long-term maintenance and repair costs? Choose OEM Brake Disc. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Avalanche 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Avalanche 1500 Brake Disc includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Avalanche 1500 Brake Disc Parts Questions & Experts Answers

- Q: How can the assembled lateral runout (LRO) of the front brake disc be corrected on Chevrolet Avalanche 1500?A:In order to fix the assembled lateral runout (LRO) of the Brake Disc, one must ensure that there is a thickness variation of the Brake Disc, by going beyond the maximum allowable level can cause brake pulsation. Start by removing the conical Brake Disc washers (J 45101-100) and lug nuts that were put in place when taking lro measurement. Check the mating surface of the hub- axle flange, and Brake Disc for foreign part oo leakcs. Next, orientate the Brake Disc in an alternated direction to the hub/axle flange and hold it firm in place and install one conical Brake Disc washer (J 45101-100) and one lug nut on the top most wheel-stud and torque the lug nut using hand torque only. Keep holding the disc steady as you mount the remaining conical Brake Disc washers (J 45101-100) and lug nuts onto the wheel studs until they are hand-tightened in a star-pattern. With the help of the torque-limiting socket set (J 39544-KIT), loosen the lug nuts then tighten them in a star-shape pattern to specifications so that the disc may be properly secured. Measure the braided lro of the Brake Disc and compare the measurement with the original. If it meets specifications, then proceed to install the brake caliper and push the brake pedal severally to hold the disc in position before removing the conical Brake Disc washers j 45101-100 as well as the lug nuts. If the measurement does not meet specifications, redo the indexing and tightening of the process until you have your best assembled lro measurement and matchmark the location of the disc to the wheel studs if your orientation is not the same as the original. In the event that the assembled lro exceeds the maximum specification, one may need to make further correction.