ChevyParts

My Garage

My Account

Cart

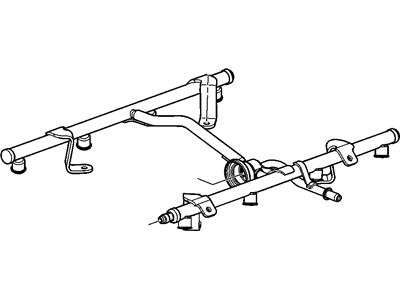

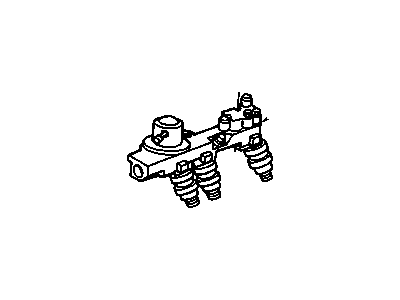

OEM Chevrolet Camaro Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Fuel Rails found

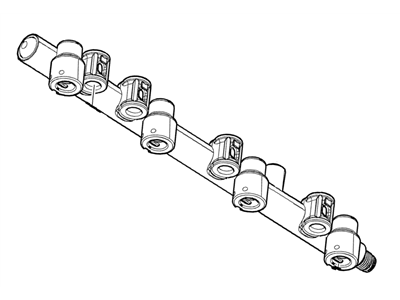

Chevrolet Camaro Fuel Rail Part Number: 12633513

$203.42 MSRP: $382.00You Save: $178.58 (47%)Ships in 1-2 Business Days

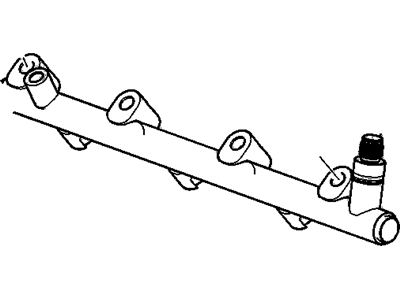

Chevrolet Camaro Fuel Rail Part Number: 12623366

$151.28 MSRP: $297.74You Save: $146.46 (50%)Ships in 1-2 Business Days

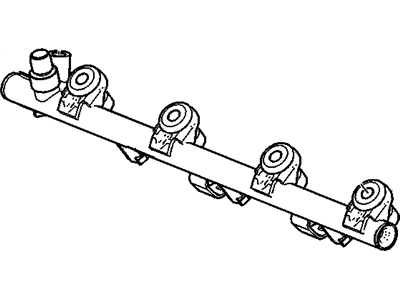

Chevrolet Camaro Fuel Rail Part Number: 12629929

$160.74 MSRP: $326.46You Save: $165.72 (51%)

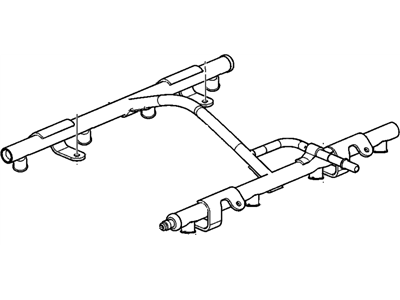

Chevrolet Camaro Fuel Rail Part Number: 12633511

$275.12 MSRP: $558.78You Save: $283.66 (51%)Ships in 1-2 Business Days

Chevrolet Camaro Fuel Rail Part Number: 12623365

$163.31 MSRP: $295.58You Save: $132.27 (45%)Ships in 1-2 Business DaysChevrolet Camaro Fuel Rail Part Number: 12701658

$183.80 MSRP: $329.68You Save: $145.88 (45%)Ships in 1-3 Business DaysChevrolet Camaro Fuel Rail Part Number: 12654644

$251.84 MSRP: $455.82You Save: $203.98 (45%)Ships in 1-3 Business DaysChevrolet Camaro Fuel Rail Part Number: 12729466

$117.50 MSRP: $238.66You Save: $121.16 (51%)Chevrolet Camaro Fuel Rail Part Number: 12701133

$117.50 MSRP: $238.66You Save: $121.16 (51%)Ships in 1-2 Business DaysChevrolet Camaro Fuel Rail Part Number: 12707883

$117.50 MSRP: $238.66You Save: $121.16 (51%)Ships in 1-3 Business DaysChevrolet Camaro Fuel Rail Part Number: 12709433

$125.97 MSRP: $225.96You Save: $99.99 (45%)Chevrolet Camaro Fuel Rail Part Number: 12729464

$117.50 MSRP: $238.66You Save: $121.16 (51%)Ships in 1-2 Business DaysChevrolet Camaro Fuel Rail Assembly Part Number: 17113232

Chevrolet Camaro Fuel Rail Part Number: 17113194

Chevrolet Camaro Fuel Rail Part Number: 17112993

Chevrolet Camaro Fuel Rail Part Number: 12561858

Chevrolet Camaro Fuel Rail Assembly Part Number: 17113229

Chevrolet Camaro Fuel Rail Part Number: 17113227

Chevrolet Camaro Fuel Rail Assembly Part Number: 17113225

Chevrolet Camaro Fuel Rail Assembly Part Number: 17113226

| Page 1 of 2 |Next >

1-20 of 26 Results

Chevrolet Camaro Fuel Rail

Want to cut long-term maintenance and repair costs? Choose OEM Fuel Rail. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Camaro parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Camaro Fuel Rail includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Camaro Fuel Rail Parts and Q&A

- Q: How to service and repair the fuel rail on Chevrolet Camaro?A:A service or repair of the Fuel Rail starts with removing fuel pressure from the system by using the fuel line quick-connect separator (J 37088-A). Proper sanitation can be achieved by using caps and plugs to seal off the fittings and prevent outside materials from entering. Clean up the Fuel Rail assembly before removing the fuel feed pipe and return hose along with Fuel Injector coil wires the vacuum tube to the Fuel Pressure Regulator and MAP Sensor electrical connection cable and vacuum line to the vacuum switch and finally detach the vacuum air from the Intake Manifold. Before proceeding with the Fuel Rail bolt removal step the technician must first disconnect the Fuel Injector electrical connectors and harness fasteners. Use equal pressure to carefully pull out the Fuel Rail from the Intake Manifold before extracting the front Fuel Injector retaining clips and injectors. Installation requires replacing all components' o-rings followed by applying clean engine oil to them before setting the Fuel Rail assembly onto the Intake Manifold without front fuel injectors. The front fuel injectors require manual seating after reinstalling them along with their retaining clips. Fasten the Fuel Rail hold-down bolts at 10 n.m (89 lb in) then rejoin all Fuel Injector harness fasteners and electrical connector cables. Reinstall the vacuum source with all related lines along with fuel feed and return pipes and the MAP Sensor electrical connector and the Fuel Injector coil wires. The negative Battery Cable gets reattached and a leak check needs to be conducted by executing the specified ignition procedures.

- Q: How to replace the Fuel Injection Fuel Rail Assembly for Bank 2 on Chevrolet Camaro?A:The first step for replacing the fuel injection Fuel Rail assembly for bank 2 is to reduce fuel system pressure. Start by removing the fuel pipe shield together with the high pressure fuel sensor. Start by removing the Fuel Rail crossover pipe which then gets disposed. The bank 2 Fuel Rail must be carefully lifted with care toward the engine opening after you remove its Fuel Rail bolts. All direct Fuel Injector hold down clamps must be discarded because rebuilding is required after free release from Fuel Rail or cylinder head positions. The procedure requires rebuilding of all fuel injectors following the removal of the Fuel Rail. Reinstall the rebuilt direct fuel injectors throughout the cylinder heads by using new direct injector hold down clamps for securing. Apply gm p/n 12345610 (Canadian P/N 9931930) or equivalent engine oil as a lubricant to the Fuel Injector cups of the new Fuel Rail. Start positioning the Fuel Rail by setting the front end against the front injector while turning the rear section downwards. Start by tightening first the two outer Fuel Rail bolts before proceeding with the two inner bolts while keeping hand pressure on the wrench. The technician should tighten the Fuel Rail bolts with a specified order starting from 12 nm (106 lb in) in the first pass followed by 23 nm (17 lb ft) in the final pass. The technician should begin by installing the new crossover fuel pipe and high pressure fuel sensor but must pay attention to secure proper routing of the electrical wires to prevent damage. Connect the electrical connector of the Fuel Injector wiring harness to all three components which include fuel injectors and Fuel Rail and fuel pressure sensor. A leak inspection procedure entails turning on the ignition while the engine stays off for 2 seconds followed by 10 seconds of engine off and a second ignition turn-on to check for fuel leaks. The replacement sequence concludes with the installations of the fuel pipe shield and low side fuel pressure service port cap and fuel tank cap.