ChevyParts

My Garage

My Account

Cart

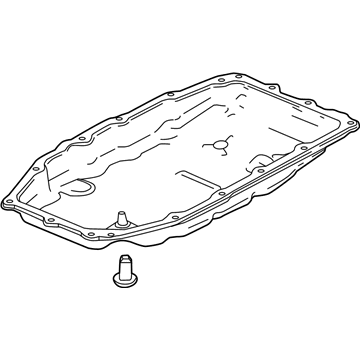

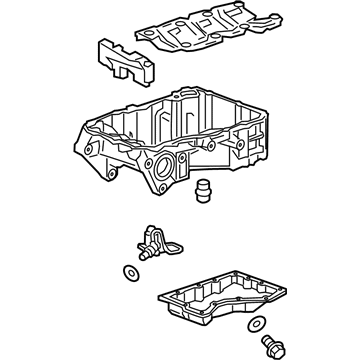

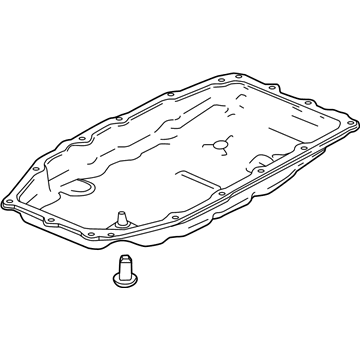

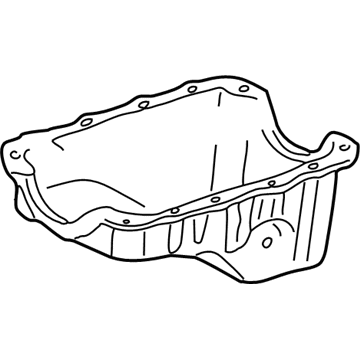

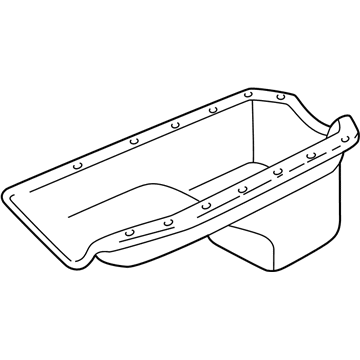

OEM Chevrolet Camaro Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Oil Pans found

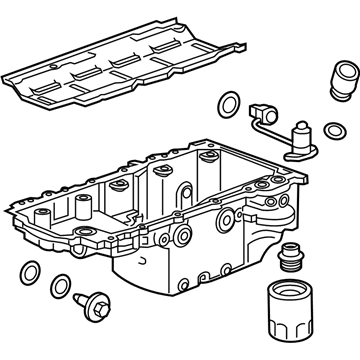

Chevrolet Camaro Oil Pan Part Number: 12639931

$1753.79 MSRP: $2771.91You Save: $1018.12 (37%)

Chevrolet Camaro Oil Pan Part Number: 12641015

$210.44 MSRP: $328.16You Save: $117.72 (36%)Ships in 1-2 Business Days

Chevrolet Camaro Oil Pan Part Number: 12673901

$27.04 MSRP: $44.54You Save: $17.50 (40%)Ships in 1-2 Business Days

Chevrolet Camaro Oil Pan Part Number: 12557558

$175.72 MSRP: $301.79You Save: $126.07 (42%)Ships in 1-3 Business DaysChevrolet Camaro Oil Pan Part Number: 12626225

$519.94 MSRP: $821.42You Save: $301.48 (37%)Ships in 1-3 Business DaysChevrolet Camaro Oil Pan, Upper Part Number: 12676339

$71.21 MSRP: $111.54You Save: $40.33 (37%)Ships in 1-3 Business DaysChevrolet Camaro Oil Pan Part Number: 12630705

$116.94 MSRP: $183.96You Save: $67.02 (37%)Ships in 1-3 Business DaysChevrolet Camaro Oil Pan Part Number: 12664619

$605.42 MSRP: $821.42You Save: $216.00 (27%)Chevrolet Camaro Oil Pan Part Number: 12711496

$226.81 MSRP: $356.80You Save: $129.99 (37%)Ships in 1-3 Business DaysChevrolet Camaro Oil Pan Part Number: 24045034

$40.90 MSRP: $69.63You Save: $28.73 (42%)Ships in 1-2 Business DaysChevrolet Camaro Oil Pan Part Number: 12671425

$245.38 MSRP: $386.09You Save: $140.71 (37%)Ships in 1-3 Business DaysChevrolet Camaro Oil Pan Part Number: 12716562

$201.07 MSRP: $316.31You Save: $115.24 (37%)Ships in 1-3 Business DaysChevrolet Camaro Oil Pan Part Number: 25202732

$122.67 MSRP: $192.98You Save: $70.31 (37%)Ships in 1-3 Business DaysChevrolet Camaro Oil Pan Part Number: 12707561

$1753.79 MSRP: $2771.91You Save: $1018.12 (37%)Chevrolet Camaro Oil Pan Part Number: 24288492

$119.96 MSRP: $206.02You Save: $86.06 (42%)Ships in 1-2 Business DaysChevrolet Camaro Oil Pan Part Number: 10115790

Chevrolet Camaro Oil Pan Part Number: 10044683

Chevrolet Camaro Oil Pan Part Number: 12676336

Chevrolet Camaro Oil Pan Part Number: 12563241

Chevrolet Camaro Oil Pan Part Number: 14082348

| Page 1 of 2 |Next >

1-20 of 26 Results

Chevrolet Camaro Oil Pan

Want to cut long-term maintenance and repair costs? Choose OEM Oil Pan. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Camaro parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Camaro Oil Pan includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

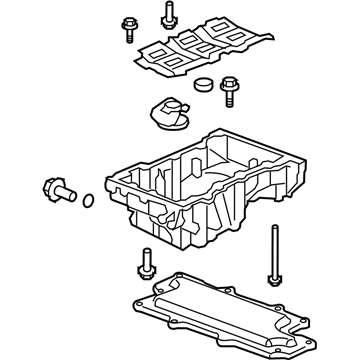

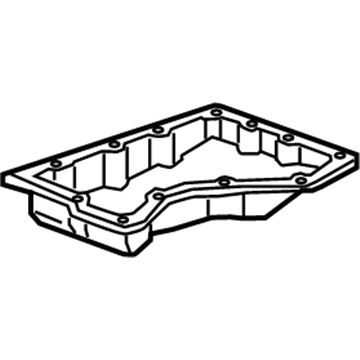

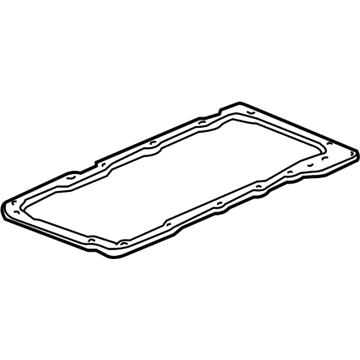

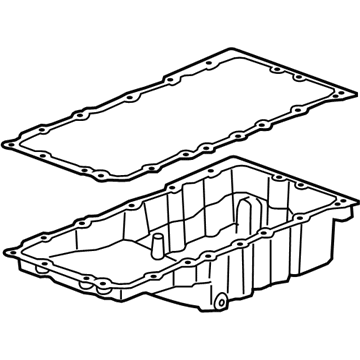

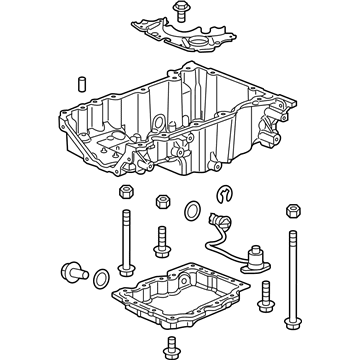

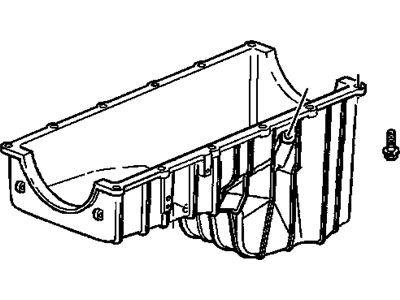

Refers to the Oil Pan employed in Chevrolet Camaro vehicles, This works as a receptacle that holds the Engine oil that is compulsory for the Camaro vehicle's efficient and effective operation. Compared to one of its counterparts, the Oil Pan is situated below the engine in order to both avoid leakage and provide enough of the fluid to supply metal components with lubrication. For many years of Chevrolet Camaro generations, there were different types of Oil Pan which also affected the performance specifically on the high-stress times such as cornering time. Conventional/normal oil pans are capable of developing oil slosh and may cause lots of problems when it comes to lubrication, some exotic systems like the "dry sump" has been used in certain high-performance applications. It employs the scavenge pumps together with a swirl tank to enhance simple oil movement and thus ensure that the oil is adequately circulated even under the harshest environmental conditions.

Chevrolet Camaro Oil Pan Parts Questions & Experts Answers

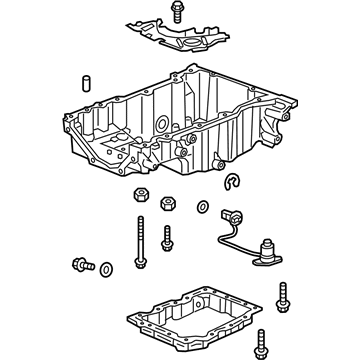

- Q: How to service and repair the oil pan on Chevrolet Camaro?A:Use the engine support fixture to first fix it to the engine while raising the vehicle securely in order to service or repair the Oil Pan. Drain the engine oil, then remove the right side mount to cradle bolts, left side mount to cradle bolts, the right side mount to shock absorber lower bolts, and the left side mount to shock absorber lower bolts. Then, elaborate from the Steering Shaft bolt, the intermediation and the rack pinions and underlay the engine cradle with the proper equipment. Disconnect the oil level sensor electrical connector and remove the oil level sensor of the Oil Pan so that it doesn't sustain any damage. Proceed to compress the Starter motor, front crossmember bolts and the Oil Pan bolts first in order to bend the rear of the Oil Pan whilst tilting it outwards in order to remove together with the Oil Pan Gasket. Clean the mating surface for Oil Pan Gasket before fitting a new Oil Pan pan gasket and the Oil Pan. Tighten the Oil Pan bolts to 14nm (10 ft. Lbs.), and then tighten the front crossmember bolts: upper four bolts to 125 nm (92 ft. Lbs.), lower bolts to 145 nm (107 ft. Lbs.). Now re-install the Starter motor and the oil level sensor on the Oil Pan, follow by tightening to 20 nm (15ft. Lbs) follow by the electrical connector on the oil level sensor. Removal of the equipment that supported the engine cradle, then installation of the intermediate Steering Shaft from the Rack And Pinion, tightening intermediate shaft bolt to 47 nm (35 ft. Lbs.). Mount and secure the right and the left side shock absorber lower mounting studs in 65 nm (48 ft. Lbs.); following this secure the left side Engine Mount to cradle bolts at 58 nm (43 ft. Lbs.) and right side Engine Mount to cradle at 58 nm (43 ft. Lbs.). Finally, lower the vehicle, then detach the engine support fixture, and change the engine oil and filter.