ChevyParts

My Garage

My Account

Cart

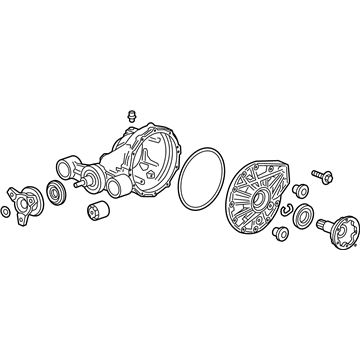

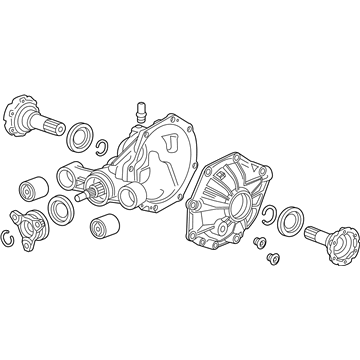

OEM Chevrolet Differential

Front Differential- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

241 Differentials found

Chevrolet Bearing Housing Part Number: 84653459

$3282.25 MSRP: $4224.24You Save: $941.99 (23%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Carrier, With Cap; Differential; Carrier Assembly; Carrier; Carrier,With Cap

- Replaces: 24255988, 84300363, 23398957, 23255920, 23213561

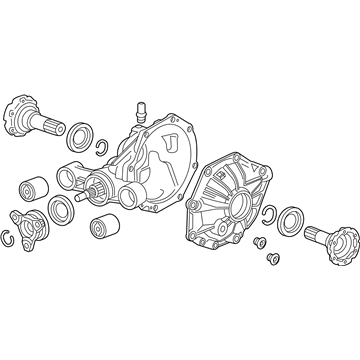

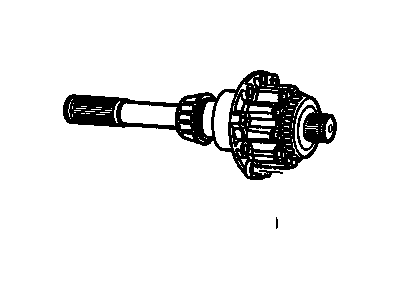

Chevrolet Differential Assembly Part Number: 84637772

$1991.99 MSRP: $3148.41You Save: $1156.42 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Carrier, With Cap; Differential; Carrier; Carrier, Final Drive

- Replaced by: 86827957

Chevrolet Differential Assembly Part Number: 84637774

$2889.37 MSRP: $3718.63You Save: $829.26 (23%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Carrier, With Cap; Differential; Carrier; Carrier, Final Drive

- Replaces: 84234638, 84080677, 84382591

Chevrolet Differential Assembly Part Number: 86827951

$1957.17 MSRP: $2518.89You Save: $561.72 (23%)Product Specifications- Other Name: Carrier, With Cap; Carrier; Carrier, Final Drive

- Replaces: 23384523, 84234636, 84035825, 84371223, 84060181

Chevrolet Differential Assembly Part Number: 86827953

$2404.72 MSRP: $3094.87You Save: $690.15 (23%)Product Specifications- Other Name: Carrier, With Cap; Carrier; Carrier, Final Drive

- Replaces: 84637768, 84080678, 23384526, 84080676, 84234639, 84007707

Chevrolet Ring Gear Part Number: 84300373

$1688.37 MSRP: $2264.76You Save: $576.39 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Carrier, With Cap; Gear Set, Ring And Pinion

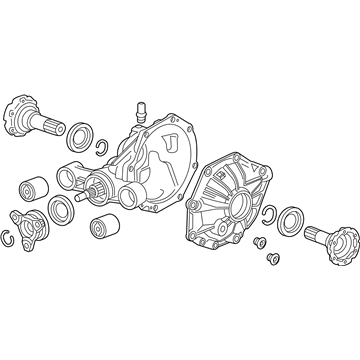

Chevrolet Differential Assembly Part Number: 86827956

$1907.18 MSRP: $2455.27You Save: $548.09 (23%)Product Specifications- Other Name: Carrier, With Cap; Carrier; Carrier, Final Drive

- Replaces: 84637771, 84080675, 23384530, 84382588, 84080682, 84234643

Chevrolet Differential Assembly Part Number: 86827952

$1947.43 MSRP: $2506.35You Save: $558.92 (23%)Product Specifications- Other Name: Carrier, With Cap; Carrier; Carrier, Final Drive

- Replaces: 84060182, 84371224, 84035826, 84234637

Chevrolet Differential Assembly Part Number: 84382590

$2733.65 MSRP: $3518.22You Save: $784.57 (23%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Carrier, With Cap; Differential; Carrier; Carrier, Final Drive

- Replaced by: 84637773

Chevrolet Differential Assembly Part Number: 86827954

$2404.72 MSRP: $3094.87You Save: $690.15 (23%)Product Specifications- Other Name: Carrier, With Cap; Carrier; Carrier, Final Drive

- Replaces: 84080679, 84080672, 84637769, 84234640, 23384527

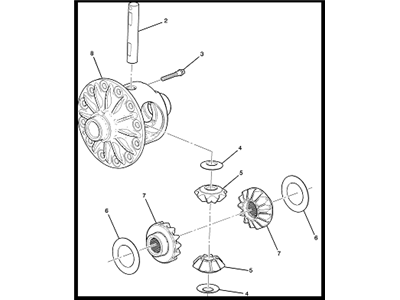

Chevrolet Differential Case Part Number: 22943115

$783.75 MSRP: $1035.75You Save: $252.00 (25%)Product Specifications- Other Name: Differential, Differential Side With Pinion; Differential, Front/Rear Differential And Planet; Differential

Chevrolet Ring Gear Part Number: 84653465

$3078.63 MSRP: $3962.19You Save: $883.56 (23%)Product Specifications- Other Name: Carrier, With Cap; Differential; Carrier Assembly; Carrier; Carrier,With Cap

- Replaces: 23255926, 84055661, 84300369

Chevrolet Carrier Part Number: 23213558

$2600.70 MSRP: $3347.10You Save: $746.40 (23%)Product Specifications- Other Name: Carrier, With Cap; Carrier,With Cap

- Replaces: 24255985

Chevrolet Carrier Assembly Part Number: 23255925

$2831.20 MSRP: $3644.85You Save: $813.65 (23%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Carrier, With Cap; Differential; Carrier; Carrier,With Cap

- Replaced by: 84653464

Chevrolet Bearing Housing Part Number: 84653462

$3080.17 MSRP: $3965.36You Save: $885.19 (23%)Product Specifications- Other Name: Carrier, With Cap; Differential; Carrier Assembly; Carrier; Carrier,With Cap

- Replaces: 23255923, 84300366

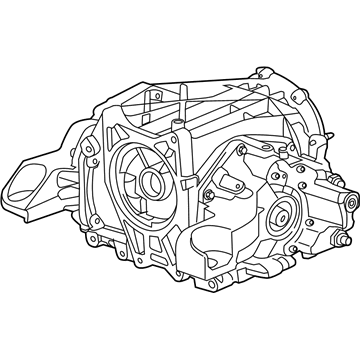

Chevrolet Transfer Case Part Number: 84978148

$1386.21 MSRP: $1549.22You Save: $163.01 (11%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Case Assembly-Transfer; Case, Transfer Case

- Replaced by: 86305269

Chevrolet Carrier Assembly Part Number: 84300368

$2831.20 MSRP: $3644.85You Save: $813.65 (23%)Product Specifications- Other Name: Carrier, With Cap; Differential; Carrier; Carrier,With Cap

- Replaced by: 84653464

- Replaces: 24260557, 23255925, 84055660

Chevrolet Differential Part Number: 19181796

$631.54 MSRP: $834.60You Save: $203.06 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Differential, Differential Side With Pinion; Differential, Differential(Ring Gear And Pinion); Differential, Differential Side

Chevrolet Carrier Assembly Part Number: 23213556

$2316.86 MSRP: $2981.81You Save: $664.95 (23%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Carrier, With Cap; Differential; Carrier; Carrier,With Cap

Chevrolet Differential Case Part Number: 10046381

Product Specifications- Other Name: Case; Differential; Case, Differential(Ring Gear And Pinion)

| Page 1 of 13 |Next >

1-20 of 241 Results

Chevrolet Differential

Want to cut long-term maintenance and repair costs? Choose OEM Differential. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Differential includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Differential Parts Questions & Experts Answers

- Q: How should the differential case components be cleaned and inspected for damage on Chevrolet Corvette?A:Clean the differential case components in solvent and examine them for cracks, improper shape of threaded bolt holes, severe wear, scoring, or grooving in the clutch pack area, and scored or damaged case side bearing flange. When cleaning the gears and shafts, use a solvent and check the gears for chips, cracks, pitting, heat discoloration, abnormal wear, high wear or scoring in side gear pin bores, excessive wear or scoring on side gear washing, abnormal wear or grooves on output gears splines, damage to side gear threaded bolt holes, unusual wear or grooves on ring gear; damage to ring gear vehicle speed interval relucor ring lobes. Check the shafts for abnormal wear, grooved, worn or damaged splines, and an impaired C-clip groove. Wipe the discs and plates down with solvent and check them for abnormal wear, scoring or grooving on the separator plate friction surfaces friction plates with uneven wear or worn friction material, bent or warped plates or discs, and worn, scored, or collapsed Belleville washer. Lay the plates and discs on a flat surface to check for warpage. Examine the bearing rollers and cups for pitting, scoring, grooves, excessive wear, or some other defect, and observe heat discoloration of yellow to dark blue tones, indicating excessive loading or improper lubrication; bearings or cups depicting heat decolorization should be replaced. In addition, look for deformed or damaged bearing cages.

- Q: How to replace the Differential Carrier Assembly on a 4.2L In-Line Six Cylinder on Chevrolet Trailblazer?A:In order to replace the Differential carrier assembly on a 4.2l in-line six cylinder, remove the front tires and the wheels, and later on, the engine protection shield. Remove the engine oil and front drive axle, followed by disconnecting the front propeller shaft from front axle. It wraps the bearing caps with tape in order to prevent loss of roller bearings and removes the abs wiring harness of the retainers, the brake hose retaining bolts, and the front drive axle vent hose. Then, remove the left and right upper ball pinch bolt and nut, the left and right upper shock module retaining nuts, and the front stabilizer bar links from frame. Remove the front drive axle of each front wheel drive along the output of the front drive axle, secure each front wheel drive of the front drive axle to the frame with mechanics wire or hook to suspend the front shock module and Steering Knuckle. Unscrew the power steering gear assembly, the inner shaft of the front drive axle, and the front drive axle from the Oil Pan, then take off the Oil Pan and front drive axle out of the vehicle. For installation, begin by securing the front drive axle to the frame and install the Oil Pan. Mount the front drive axle to the Oil Pan and make sure the front drive axle mounting bolts have been installed properly and secured to a torque of 85 nm (63 ft. Lbs.). Next, place the inner axle to the front drive axle and to power steering gear. Take the left and right front wheel drive shafts out of the frame, then take off the left and right shock module and steering knuckles from its support. Mount the right and left front wheel drive shafts to the front drive axle, the vent hose at the front drive axle and the left and right shock modules at the frame and tighten the upper shock module retaining nuts to 100 nm (74 ft. Lbs.). Take the Steering Knuckle, join it with the upper Control Arm, put on the upper ball joint pinch bolt and nut, while tightening the upper side of the shock module bolts to 40 nm (30 ft. Lbs.). Connect the front stabilizer bar links to the frame, the brake hose retaining bolts (to 25 Nm (18 ft. Lbs.)), and the right and left abs wiring harness to the retainers. Lastly, replace the front propeller shaft from the front axle, refilling the front drive axle with, and engine fluids, proper, install the engine protection shield, and replace the tires and wheels.

Related Chevrolet Parts

Browse Chevrolet Differential by Models

S10 Colorado C10 Tahoe Camaro Equinox Impala SS SSR Avalanche Silverado 1500 Silverado 2500 HD Caprice Suburban Traverse Blazer Tracker K10 Trax Trailblazer Astro Corvette C20 C1500 C2500 C30 C3500 Express 1500 Express 2500 Express 3500 G10 G20 G30 K1500 K20 K2500 K30 K3500 K5 Blazer Monte Carlo S10 Blazer Silverado 2500 Uplander Venture Silverado 3500 Suburban 1500 Trailblazer EXT Avalanche 1500 Avalanche 2500 C10 Suburban C1500 Suburban C20 Suburban C2500 Suburban K10 Suburban K1500 Suburban K20 Suburban K2500 Suburban R10 R10 Suburban R1500 Suburban R20 R20 Suburban R2500 R2500 Suburban R30 R3500 Silverado 1500 Classic Silverado 1500 HD Silverado 1500 HD Classic Silverado 1500 LD Silverado 1500 LTD Silverado 2500 HD Classic Silverado 3500 Classic Silverado 3500 HD Suburban 2500 Suburban 3500 HD V10 V10 Suburban V1500 Suburban V20 V20 Suburban V2500 Suburban V30 V3500