ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Express 3500 Wheel Bearing

Hub Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

20 Wheel Bearings found

Chevrolet Express 3500 Wheel Bearing Part Number: 9439561

$72.53 MSRP: $131.28You Save: $58.75 (45%)Ships in 1-2 Business Days

Chevrolet Express 3500 Wheel Bearing Part Number: 9428908

$72.07 MSRP: $98.04You Save: $25.97 (27%)Ships in 1-2 Business Days

Chevrolet Express 3500 Wheel Bearing Part Number: 9436881

$80.31 MSRP: $145.36You Save: $65.05 (45%)Ships in 1-3 Business Days

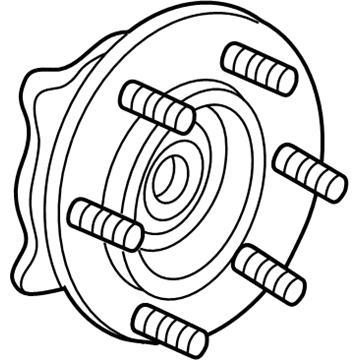

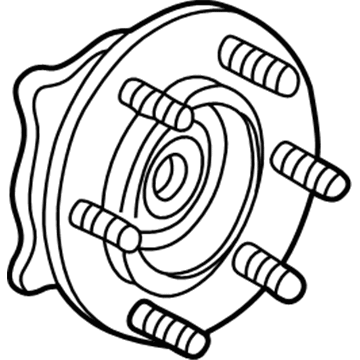

Chevrolet Express 3500 Hub, Rear Part Number: 25843093

$267.80 MSRP: $519.76You Save: $251.96 (49%)Ships in 1-2 Business Days

Chevrolet Express 3500 Wheel Bearings, Rear Part Number: 15042154

$43.95 MSRP: $86.04You Save: $42.09 (49%)Ships in 1-2 Business Days

Chevrolet Express 3500 Hub, Rear Part Number: 15715055

$162.84 MSRP: $318.82You Save: $155.98 (49%)

Chevrolet Express 3500 Wheel Bearings, Rear Part Number: 15042155

$34.70 MSRP: $102.70You Save: $68.00 (67%)Ships in 1-2 Business Days

Chevrolet Express 3500 Axle Bearings, Front Part Number: 26053326

$11.46 MSRP: $20.46You Save: $9.00 (44%)Ships in 1-3 Business Days

Chevrolet Express 3500 Wheel Bearing, Rear Part Number: 12479031

$49.62 MSRP: $96.32You Save: $46.70 (49%)Chevrolet Express 3500 Front Hub & Bearing Part Number: 85137059

$114.09 MSRP: $313.58You Save: $199.49 (64%)Chevrolet Express 3500 Hub & Bearing Part Number: 85137056

$194.41 MSRP: $380.64You Save: $186.23 (49%)Ships in 1-3 Business DaysChevrolet Express 3500 Front Hub & Bearing Part Number: 85137058

$173.61 MSRP: $339.90You Save: $166.29 (49%)Ships in 1-2 Business DaysChevrolet Express 3500 Axle Bearings Part Number: 88982517

$70.52 MSRP: $125.92You Save: $55.40 (44%)Ships in 1-2 Business DaysChevrolet Express 3500 BEARING,DIFF Part Number: 09436881

$73.98 MSRP: $132.10You Save: $58.12 (44%)Chevrolet Express 3500 Hub & Bearing Part Number: 84915033

$182.57 MSRP: $354.35You Save: $171.78 (49%)Ships in 1-2 Business DaysChevrolet Express 3500 RR WHL BRG Part Number: 09439561

$71.36 MSRP: $122.50You Save: $51.14 (42%)Chevrolet Express 3500 Wheel Bearings Part Number: 457043

$59.61 MSRP: $98.54You Save: $38.93 (40%)Ships in 1-2 Business DaysChevrolet Express 3500 Wheel Bearing, Front Part Number: 457232

$29.38 MSRP: $50.52You Save: $21.14 (42%)Ships in 1-2 Business Days

Chevrolet Express 3500 Front Hub Part Number: 15233113

Chevrolet Express 3500 Hub, Rear Part Number: 15650041

Chevrolet Express 3500 Wheel Bearing

Want to cut long-term maintenance and repair costs? Choose OEM Wheel Bearing. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Express 3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Express 3500 Wheel Bearing includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Express 3500 Wheel Bearing Parts Questions & Experts Answers

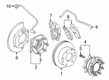

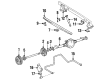

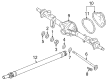

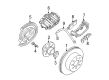

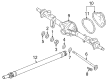

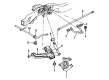

- Q: How to service the front wheel bearing and hub on Chevrolet Express 3500?A:To access the front Wheel Bearing and hub you should first lift the vehicle and secure it on safety stands. Place wire support under the caliper to protect Brake Line while also disconnecting it from the front brake caliper. Use a tool to unwrap the dust cap from the hub/rotor assembly. Pull out the cotter pin afterward and release the nut with washer before damaging thread patterns. Detach the rotor from the Spindle while taking out the outer bearing. After that, use a flat tool to extract the protective rubber piece. Dispose it during the process. Only disconnect the inner bearing unit without letting compressed air turn the wheel bearings to avoid harming them. Soak all parts in solvent then let them air dry until they no longer show grease residue. Check the rotor and bearing parts for damage or signs of wear and replace those with issues. Before assembly apply approved high-temperature front Wheel Bearing grease to the Spindle threads at all bearing positions and their shaft surfaces. Pack grease by hand into each bearing cup area just inside the hub/rotor. Then work the grease properly through all rollers, cone, and cage components of the plain bearings. Place the inner bearing onto the rotor then put more grease around it before coating the seal lip and tapping the seal tightly without harming Spindle threads during installation. Keep these wheel bearings aligned by first fitting the hub/rotor onto the Spindle before placing the outer bearing and washer parts beneath it. Complete the process by adjusting the wheel bearings until they function properly. Put the cotter pin in place then grease the outboard side of the outer bearing before inserting the hub/rotor cap. Reposition the brake caliper and wheel parts onto the front brakes and then remove safety stands before letting the vehicle down.