ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Malibu Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Brake Discs found

Chevrolet Malibu Rotor Part Number: 13537160

$84.94 MSRP: $163.04You Save: $78.10 (48%)

Chevrolet Malibu Rotor, Front Part Number: 19303828

$52.76 MSRP: $160.27You Save: $107.51 (68%)Ships in 1-2 Business Days

Chevrolet Malibu Rotor, Rear Part Number: 23118534

$143.99 MSRP: $281.90You Save: $137.91 (49%)Ships in 1-2 Business Days

Chevrolet Malibu Rotor, Front Part Number: 23118530

$157.12 MSRP: $304.94You Save: $147.82 (49%)Ships in 1-2 Business DaysChevrolet Malibu Rotor, Rear Part Number: 23118537

$126.13 MSRP: $244.80You Save: $118.67 (49%)Ships in 1-2 Business DaysChevrolet Malibu Rotor, Front Part Number: 23118529

$97.15 MSRP: $188.55You Save: $91.40 (49%)Ships in 1-2 Business DaysChevrolet Malibu Rotor, Front Part Number: 19303826

$146.65 MSRP: $275.40You Save: $128.75 (47%)Ships in 1-2 Business DaysChevrolet Malibu Rotor Part Number: 19303823

$128.98 MSRP: $250.33You Save: $121.35 (49%)Ships in 1-2 Business DaysChevrolet Malibu Rotor, Rear Part Number: 13544245

$73.74 MSRP: $143.11You Save: $69.37 (49%)Ships in 1 Business Day

Chevrolet Malibu Rotor, Front Part Number: 19303825

Chevrolet Malibu Rotor, Front Part Number: 19213925

Chevrolet Malibu Rotor, Green Line Part Number: 19303822

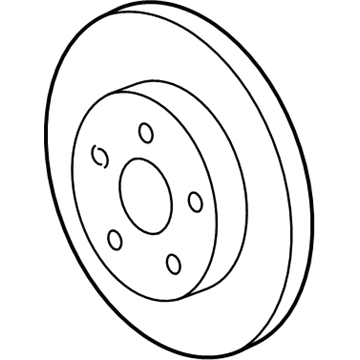

Chevrolet Malibu Brake Disc

Want to cut long-term maintenance and repair costs? Choose OEM Brake Disc. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Malibu parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Malibu Brake Disc includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Malibu Brake Disc is one of the disc brake system parts that give the braking pads a surface to move on in order to slow down our car or bring it to a complete halt. Located on the axle or hub, the rotor turns with the wheel, when the brakes ar pressed, hydraulic pressure pushes the caliper to squeeze the pad against the rotor. This design facilitates cooling particularly on the vented rotors that possess cooling flutes which are commonly mounted on the front side while the solid rotors may be fitted on the rearside of some models. Chevrolet Malibu, of course, has utilized different varieties of Brake Discs and their types which include, solid and vented and most of them are made of cast iron or polymer composites. The importance of maintenance is critical because of the rotors, these can develop problems such as scoring, warping or excessive run out which compromises the braking option. To maintain efficiency and safety of the Chevrolet Malibu vehicles it is recommended that the Brake Discs should be inspected often and replaced as soon as possible.

Chevrolet Malibu Brake Disc Parts Questions & Experts Answers

- Q: What Tools Are Required to Service and Repair the Brake Disc, and What Steps Should Be Followed to Ensure Proper Refinishing on Chevrolet Malibu?A:You need the rotating and wheel hub resurfacing kits to work on brake discs. The tools are J 41013 and J 42450-A. Disc brake discs only need touch-up when they show signs of major corrosion, holes, cracks, hot spots, extreme discoloration from heat, surface faults more severe than permitted limits, or when thickness changes surpass the maximum standards. Check the disc thickness and surface for finishability while making sure the parts stay above their minimum thickness standards. Remove wheel bearing and brake disc surface corrosion with J 41013 Rotor Resurfacing Kit on the wheel bearing flange and J 42450-A Wheel Hub Resurfacing Kit on brake disc mounting surfaces. Set the brake disc on the lathe system following producer guidelines and confirm all installation parts are spotless. Adjust the cutting tools to touch the disc while the lathe runs by watching the witness marks to verify correct mounting. Remount the disc whenever the witness mark fails to cover three-quarters of its circumference. Use the lathe according to the manufacturer's guidelines while checking disc thickness after each refinement phase. The disc needs to be replaced when its thickness surpasses the set limits. For non-directional finishing use the recommended speed while sanding with 120 grit aluminum oxide sandpaper on non-directional tools or a sanding block paired with 150 grit sandpaper. Wipe the brake friction areas thoroughly using denatured alcohol or brake cleaner before taking the disc away from the lathe.