ChevyParts

My Garage

My Account

Cart

OEM GMC EGR Valve

Emissions EGR Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

69 EGR Valves found

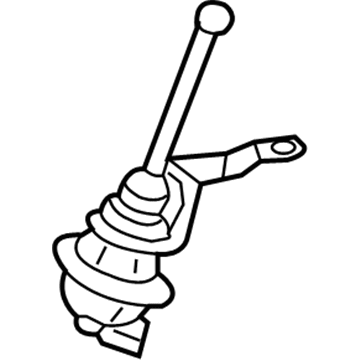

GMC Actuator Part Number: 55597899

$33.47 MSRP: $60.58You Save: $27.11 (45%)Product Specifications- Other Name: Actuator, Emission Control System

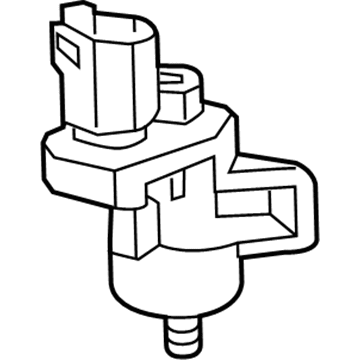

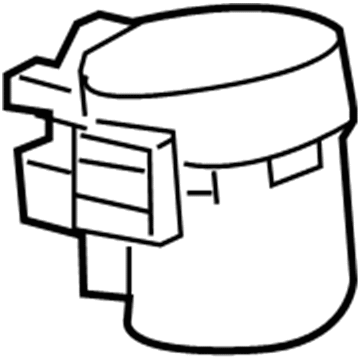

GMC EGR Solenoid Part Number: 55574896

$28.18 MSRP: $52.92You Save: $24.74 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Solenoid; Exhaust Gas Recirculation (EGR) Valve; EGR Vacuum Solenoid; Vacuum Control Solenoid; Valve, Emission Control System

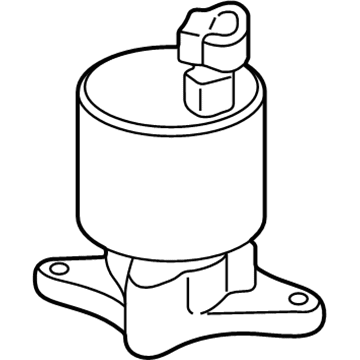

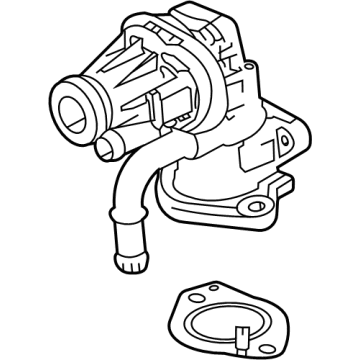

GMC EGR Valve Part Number: 12578036

$227.86 MSRP: $427.91You Save: $200.05 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve, Emission Control System; EGR Vacuum Solenoid

- Replaces: 17096306, 17113712

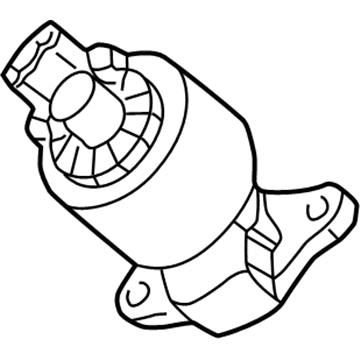

GMC EGR Valve Part Number: 97288827

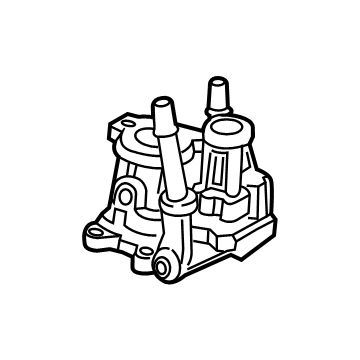

$286.83 MSRP: $451.31You Save: $164.48 (37%)Product Specifications- Other Name: Valve Assembly, EGR; EGR Vacuum Solenoid; Valve, Emission Control System

GMC EGR Valve Part Number: 12689249

$230.80 MSRP: $468.76You Save: $237.96 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve-EGR; EGR Vacuum Solenoid

- Replaced by: 12741983

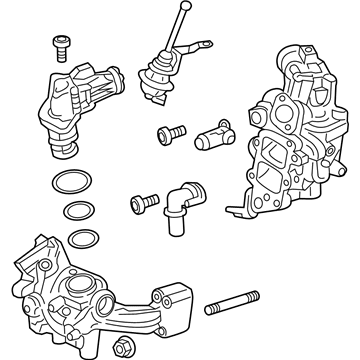

GMC EGR Valve Part Number: 12640017

$280.47 MSRP: $526.70You Save: $246.23 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve Kit, Emission Control System; EGR Vacuum Solenoid

GMC EGR Valve Part Number: 19210641

$61.88 MSRP: $125.68You Save: $63.80 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve Kit, EGR; EGR Vacuum Solenoid; Valve, Emission Control System (ECM Components, EGR Control, EGR Valves)

- Replaces: 17111848

GMC EGR Valve Part Number: 55510043

$123.35 MSRP: $221.26You Save: $97.91 (45%)Product Specifications- Other Name: Valve Assembly-EGR; EGR Vacuum Solenoid; Valve, Emission Control System

GMC EGR Valve Part Number: 12578044

$194.66 MSRP: $352.33You Save: $157.67 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve, Emission Control System; EGR Vacuum Solenoid

- Replaces: 17113279, 17113534, 17093134

GMC Solenoid Valve Part Number: 13576005

$26.28 MSRP: $47.56You Save: $21.28 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Solenoid, Evaporator Emission Canister; Vapor Canister Vent Solenoid; Vent Control Solenoid; Solenoid, Fuel Tank Evaporator/Purge Control

GMC EGR Valve Part Number: 19210677

$80.13 MSRP: $162.74You Save: $82.61 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve Kit, EGR; EGR Vacuum Solenoid

- Replaces: 17093157, 17113501

GMC EGR Valve Part Number: 19210653

$59.07 MSRP: $184.27You Save: $125.20 (68%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve Kit, EGR; EGR Vacuum Solenoid; Valve, Emission Control System (ECM Components, EGR Control)

- Replaces: 17111843, 17113370

GMC EGR Valve Part Number: 17066253

$55.94 MSRP: $174.49You Save: $118.55 (68%)Ships in 1-2 Business DaysProduct Specifications- Other Name: EGR Vacuum Solenoid

- Replaced by: 19210681

GMC EGR Valve Part Number: 98025781

$397.19 MSRP: $624.95You Save: $227.76 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Valve Assembly-EGR; EGR Vacuum Solenoid; Valve, Emission Control System

- Replaces: 97379347

GMC Solenoid Valve Part Number: 1997207

$31.87 MSRP: $59.47You Save: $27.60 (47%)Product Specifications- Other Name: Solenoid Assembly-EGR Control Valve Relay; Vapor Canister Purge & Vent Solenoids; EGR Vacuum Solenoid.; EGR Solenoid; Vacuum Solenoid; Control Solenoid; Vacuum Control Solenoid; Solenoid, Emission Control System

GMC EGR Valve Part Number: 19210662

$78.81 MSRP: $140.73You Save: $61.92 (44%)Product Specifications- Other Name: Valve Kit, EGR; EGR Vacuum Solenoid; Valve, Emission Control System(EGR Control); Valve, Emission Control System

- Replaces: 17111854, 17113457, 17111855, 17111853

GMC EGR Valve Part Number: 19210639

$104.81 MSRP: $187.16You Save: $82.35 (44%)Product Specifications- Other Name: Valve Kit, EGR; EGR Vacuum Solenoid; Valve, Emission Control System (ECM Components, EGR Control, EGR Valves)

- Replaces: 17112041

GMC EGR Valve Part Number: 17113485

Product Specifications- Other Name: Valve Assembly, EGR; EGR Vacuum Solenoid; Valve, Emission Control System

- Replaces: 17111572

GMC EGR Valve Part Number: 17112006

Product Specifications- Other Name: Valve Assembly-EGR; EGR Vacuum Solenoid

- Replaced by: 19210665

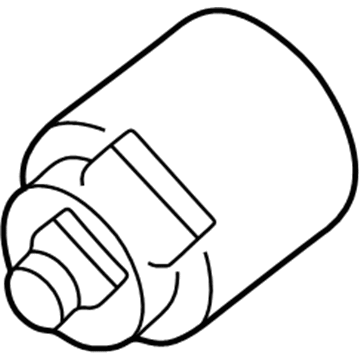

GMC Pressure Sensor Part Number: 55514983

$159.47 MSRP: $286.04You Save: $126.57 (45%)Product Specifications- Other Name: Valve Assembly-Exhaust Back Pressure; Exhaust Gas Differential Pressure Sensor; Pressure Valve; Valve, Emission Control System

- Replaces: 55510137

| Page 1 of 4 |Next >

1-20 of 69 Results

GMC EGR Valve

Want to cut long-term maintenance and repair costs? Choose OEM EGR Valve. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC EGR Valve includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC EGR Valve Parts Questions & Experts Answers

- Q: How to service the EGR Valve without disassembling it on GMC Savana 3500?A:Service the linear EGR Valve under the condition that disassembly should be avoided since it requires full assembly service. Take note of the exhaust gas recirculation valve position before removal to make sure it does not rotate by 180 degrees. Start by disconnecting the Battery Cable and taking out the air cleaner assembly from its position. Service the EGR Valve by disconnecting its harness connector but keep the linear EGR Valve free from all liquid cleaners or solvents because it is an electrical component that may suffer damage. Detach the EGR Valve to flange bolts and extract the linear EGR Valve unit with its associated flange gasket. Before installing the linear EGR Valve it is necessary to thoroughly clean its gasket surface. Fix the new flange gasket to the linear EGR Valve while closely following the fastener notice. Begin by tightening each of the valve-to-flange bolts to 10 n.m until they reach 89 lb in torque while completing the second step by tightening the bolts to 25 n.m at 18 lb ft torque. The EGR Valve harness connector must be reconnected after reinstalling the air cleaner assembly while completing the process by reconnecting the negative Battery Cable.

- Q: How to replace the EGR valve on GMC Jimmy?A:The initial step for exhaust gas recirculation (EGR) valve replacement starts with releasing the negative cable connection but taking careful notes about the valve orientation during dismantlement. The procedure requires elimination of the EGR Valve harness connector followed by EGR Valve bolt removal and subsequent extraction of the EGR Valve with its integrated gasket. Before installation properly position the EGR Valve and apply a new flange gasket to the valve. Tighten the EGR Valve flange bolts first to 10 n.m (89 lb in) from a starting point and follow up by tightening them to 25 n.m (18 lb ft). Complete the process by reconnecting both the EGR Valve harness connector along with the negative Battery Cable.

Related GMC Parts

Browse GMC EGR Valve by Models

Acadia Sierra 1500 Yukon Canyon Sierra 2500 HD Terrain Envoy Sonoma Typhoon Syclone Caballero C1500 Envoy XL Envoy XUV Jimmy K1500 S15 S15 Jimmy Safari Savana 2500 Savana 3500 Sierra 2500 Sierra 3500 Yukon XL C2500 C3500 G2500 K2500 K3500 Savana 1500 Yukon XL 1500 C1500 Suburban C2500 Suburban G1500 G3500 K1500 Suburban K2500 Suburban P2500 R1500 R1500 Suburban R2500 R2500 Suburban R3500 Sierra 1500 HD Sierra 1500 Limited Sierra 2500 HD Classic Sierra 3500 Classic Sierra 3500 HD V1500 V1500 Suburban V2500 V2500 Suburban V3500 Yukon XL 2500