ChevyParts

My Garage

My Account

Cart

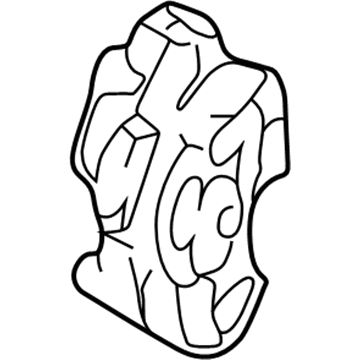

OEM Cadillac Seville Brake Calipers

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

30 Brake Calipers found

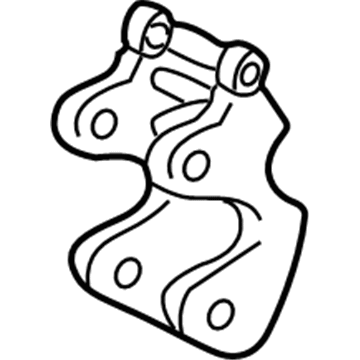

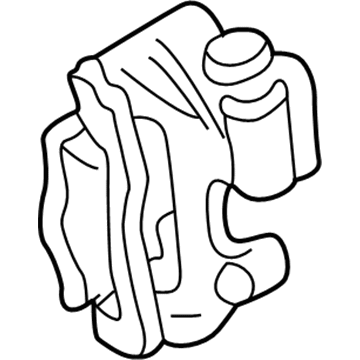

Cadillac Seville Caliper Assembly, Front Part Number: 19141283

$48.90 MSRP: $89.20You Save: $40.30 (46%)Ships in 1-3 Business DaysCadillac Seville Caliper Assembly, Front Part Number: 19141284

$33.79 MSRP: $60.04You Save: $26.25 (44%)Ships in 1-3 Business DaysCadillac Seville Caliper Assembly, Front Driver Side Part Number: 19140966

$50.00 MSRP: $91.20You Save: $41.20 (46%)Ships in 1-3 Business DaysCadillac Seville Caliper, Front Driver Side Part Number: 18046196

$145.18 MSRP: $284.26You Save: $139.08 (49%)Ships in 1-2 Business Days

Cadillac Seville Overhaul Kit, Front Part Number: 18003724

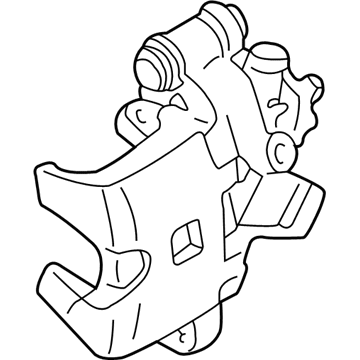

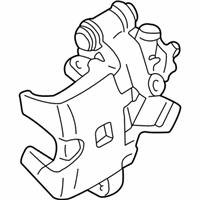

Cadillac Seville Caliper, Front Passenger Side Part Number: 18046197

Cadillac Seville Caliper Overhaul Kit, Rear Part Number: 18012689

Cadillac Seville Caliper, Rear Part Number: 19141041

Cadillac Seville Caliper, Front Passenger Side Part Number: 19132286

Cadillac Seville Caliper, Driver Side Part Number: 19132285

Cadillac Seville Caliper, Passenger Side Part Number: 18040793

Cadillac Seville Caliper Part Number: 89047664

Cadillac Seville Caliper, Front Driver Side Part Number: 18046192

Cadillac Seville Caliper Part Number: 89047663

Cadillac Seville Caliper Part Number: 88962833

Cadillac Seville Caliper Part Number: 88962834

Cadillac Seville Caliper Assembly, Driver Side Part Number: 18029830

Cadillac Seville Caliper Part Number: 89047652

Cadillac Seville Caliper Part Number: 89047654

| Page 1 of 2 |Next >

1-20 of 30 Results

Cadillac Seville Brake Calipers

Want to cut long-term maintenance and repair costs? Choose OEM Brake Calipers. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac Seville parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac Seville Brake Calipers includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Cadillac Seville Brake Calipers Parts and Q&A

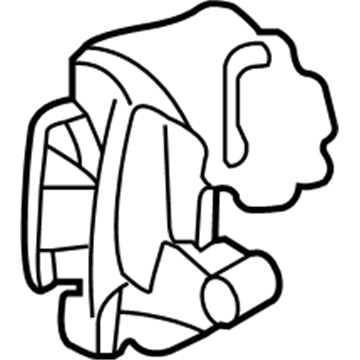

- Q: How to overhaul the front brake calipers on Cadillac Seville?A:First remove the brake caliper from the vehicle but keep your fingers away from the Piston during compressed air use to stay safe. Use clean fabric padding over inside caliper housing while removing pistons and give them space to move by applying low-pressure compressed air through the fluid access point until the pistons move out naturally. Professionalism in removing the dust boot seal from Piston as well as Piston seal from caliper unit combines plastic tool to extract these seals for disposal. Take out the bleeder valve equipment from its position in the caliper. Thoroughly clean the Piston bore and seal counterbore of the caliper with denatured alcohol or equivalent followed by filtered non-lubricated air blowing. Examine the caliper chamber for problems with its surface including cracks, damage, extreme rust damage or corrosion. Light surface rust may be cleansed with fine sandpaper but major quality defects require replacement of the whole caliper device. Replace the caliper Piston when you detect damage to chrome plating or find cracking and scoring on its surface. Dip a new Piston seal into delco supreme 11 brake fluid (GM part 12377967) from a sealed container then put it into the caliper bore. Insert the new caliper Piston into the bore space then put thedust boot seal on top of it. A dust boot seal installer designed for calipers (or a similar tool) should push the rubber seal fully into its counterbore of 78.08 mm (3.074 inch) and Piston bore of 63.52 mm (2.501 inch). Afterward, put the bleeder valve into the caliper before connecting its cap and making sure the valve remains tight. Then place the caliper back on the vehicle.

- Q: How to replace the front brake calipers on Cadillac Seville?A:Before replacing the front brake caliper you must check the brake master cylinder fluid level. Drain fluid when the level is between the minimum and midpoint of the tank. Support the vehicle at the proper height and note wheel position before taking off the tire and wheel unit. The electronic brake wear sensor clip should be lifted while disconnecting its wire and the sensor must be taken out gently from the inner Brake Pad with the tool. Pull out the sensor from the caliper after disconnecting its electrical connector at the position. Position a big c-clamp over the brake caliper to push the piston inside the caliper bore letting it pass through the rotor's path and then take off the c-clamp. Take off the brake caliper inlet fitting bolt and throw away both brake hose copper gaskets before sealing the openings with plugging material to keep fluid from escaping. Disconnect the brake caliper by taking out its two pin bolts. Before assembly you should clean brake caliper pin bolts and retainers with alcohol followed by wiping them with filtered non-oiled air. Use high-temperature silicone brake lubricant on the pin bolts but keep it away from Brake Pad hardware. Then put the caliper into place above the brake pads and mount it into the bracket. Use new copper brake hose gaskets and fasten the brake hose bolt when you tighten the brake caliper pin bolts to 85 nm (63 ft. Lbs.). Secure the brake caliper inlet bolt to 45 nm (33 ft. Lbs.) but do it in a way that allows sufficient clearance for the electronic Brake Pad wear sensor wire. Connect the electronic brake wear sensor wires to the caliper while installing the sensor onto it. Then connect the sensor connector and position the sensor under the retainer clip at the inner Brake Pad location. Use the brake pedal to reach 2/3 of its travel with the engine turned off and slowly move it back to normal with several attempts until the pedal returns to solid pressure. Place the wheel back on the vehicle before lowering it to its proper position.