ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Express 1500 Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Brake Lines found

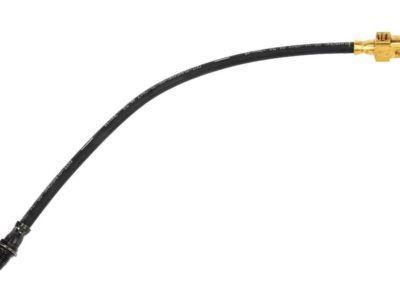

Chevrolet Express 1500 Flex Hose, Passenger Side Part Number: 84286062

$20.48 MSRP: $38.44You Save: $17.96 (47%)Ships in 1-2 Business DaysChevrolet Express 1500 Flex Hose, Driver Side Part Number: 84859048

$22.53 MSRP: $40.25You Save: $17.72 (45%)Ships in 1 Business DayChevrolet Express 1500 Flex Hose, Front Driver Side Part Number: 19366788

$46.85 MSRP: $87.99You Save: $41.14 (47%)Ships in 1-2 Business DaysChevrolet Express 1500 Flex Hose, Front Passenger Side Part Number: 19366787

$49.89 MSRP: $90.31You Save: $40.42 (45%)Ships in 1-2 Business DaysChevrolet Express 1500 Flex Hose, Rear Driver Side Part Number: 19366777

$73.88 MSRP: $144.65You Save: $70.77 (49%)Ships in 1-2 Business Days

Chevrolet Express 1500 Flex Hose, Rear Part Number: 19366771

Chevrolet Express 1500 Brake Line

Want to cut long-term maintenance and repair costs? Choose OEM Brake Line. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Express 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Express 1500 Brake Line includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Express 1500 Brake Line Parts and Q&A

- Q: How to Service and Repair Brake Lines Using the J 45405 Brake Line Flaring Kit on Chevrolet Express 1500?A:Use the J 45405 Brake Pipe Flaring Kit (J 45405) to service brake pipes with double-walled steel brake pipe and avoid brake system failure. Check the part of the brake pipe needing replacement and free it from its retainers if necessary. For brake pipe sectioning pick the right spot away from bends and mount points before measuring the required length for replacement which includes these flaring measurements 6.35 mm (0.250 inch) for 4.76 mm (3/16 inch) pipe and 9.50 mm (0.374 inch) for 6.35 mm (1/4 inch) pipe. Make straight cuts with the pipe cutter supplied in J 45405 tool. Use the coating stripping tool at the kit to remove nylon cover from the next-to-flare end. Keep the metal unaffected as you select the correct tool blade. Chamfer both the interior and exterior of the pipe using the de-burring tool from J 45405 and attach the tube nuts on the brake line. Remove dust and debris from the brake pipe and die clamp J 45405. Turn down the die screw and store the proper die set inside the die cage. Place the completed end of the pipe into the dies' backside until it fits properly. After that, screw down the clamping device. Insert the proper forming mandrel into the J 45405 tool then depress its lever to form the flare before replacing the finishing cone to repeat the process. Examine the flare for right shape and size after opening the die clamping bolt. Sought-after dimensions are 6.92 mm (0.272 inch) for 4.76 mm (3/16 inch) pipe and 8.92 mm (0.351 inch) for 6.35 mm (1/4 inch) pipe diameter. Use a suitable brake pipe bending tool to shape the new part before installing it properly with its components. Attach the pipe to retainers and finish the hydraulic brake service. Start the engine to search for leaks during brake application.

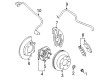

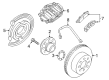

- Q: How to replace the front brake line on Chevrolet Express 1500?A:Elevate the vehicle and its suspension before taking off the tire and wheel assembly for front brake hose replacement. Remove dirt from the brake hose end and brake pipe fitting then seal them with rubber caps to keep the system clean. Hold the ratchet in position by using a back up tool on the brake hose's end. This will release its connection to the brake pipe fitting. Connect the cap or plug onto the brake pipe. Set aside the brake hose mounting bracket clip then remove engine bracket bolts from the upper Control Arm and Steering Knuckle plus squeeze the brake caliper bracket bolt. Get rid of two gaskets since they have bonded to the caliper or brake hose ends. Use 2 new copper brake hose gaskets to assemble the brake hose into the bolt before connecting it to the brake hose. Install the brake hose to caliper bolt alongside 2 new washers to the brake caliper and tighten it to 44 nm (32 ft. Lbs.). Place the brake hose in position and secure both bolts to 10 nm (88 inch lbs.) by attaching the brake hose bracket bolt to the Steering Knuckle and upper Control Arm. Pull the brake hose through the bracket slot and fasten it using the retaining clip. Connect the brake pipe fitting by putting on a back up wrench and joining it to the brake hose. Use a smooth motion while fitting the components for optimal results. Avoid bending the brake fittings and ensure both parts apply proper torque of 25 nm (18 ft. Lbs.). First drain the brake fluid system then put back the tire and wheel assembly. Also check that the brake hose stays away from suspension and tire components during harsh maneuvers. Finally, lower the vehicle.