ChevyParts

My Garage

My Account

Cart

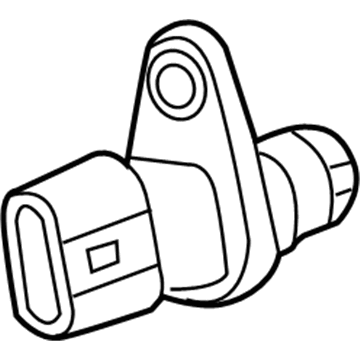

OEM Chevrolet Express 3500 Camshaft Position Sensor

Cam Position Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Camshaft Position Sensors found

Chevrolet Express 3500 Camshaft Position Sensor Part Number: 12637869

$21.95 MSRP: $41.22You Save: $19.27 (47%)

Chevrolet Express 3500 Camshaft Position Sensor Part Number: 12591720

$54.42 MSRP: $101.54You Save: $47.12 (47%)

Chevrolet Express 3500 Camshaft Position Sensor Part Number: 97365038

$81.66 MSRP: $165.86You Save: $84.20 (51%)Ships in 1-2 Business Days

Chevrolet Express 3500 Camshaft Position Sensor Part Number: 19417445

$66.52 MSRP: $124.92You Save: $58.40 (47%)Ships in 1 Business Day

Chevrolet Express 3500 Engine Camshaft Position Sensor Part Number: 12623093

$18.72 MSRP: $35.16You Save: $16.44 (47%)Ships in 1-3 Business DaysChevrolet Express 3500 Camshaft Position Sensor Part Number: 12672642

$26.15 MSRP: $49.10You Save: $22.95 (47%)Ships in 1-2 Business DaysChevrolet Express 3500 Camshaft Position Sensor Part Number: 19420911

$72.64 MSRP: $129.71You Save: $57.07 (44%)

Chevrolet Express 3500 Camshaft Position Sensor

Want to cut long-term maintenance and repair costs? Choose OEM Camshaft Position Sensor. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Express 3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Express 3500 Camshaft Position Sensor includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Express 3500 Camshaft Position Sensor Parts and Q&A

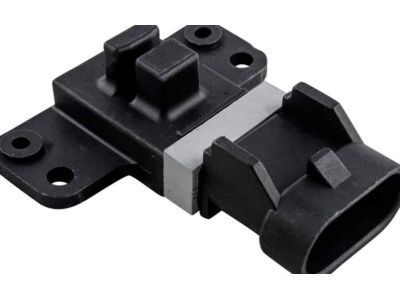

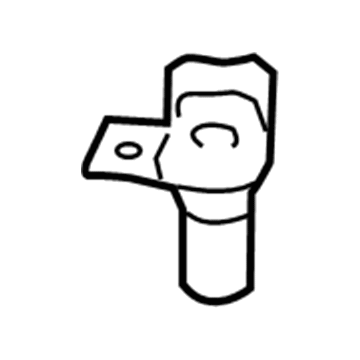

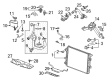

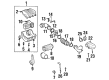

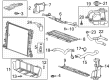

- Q: How to service and repair the Camshaft Position Sensor on Chevrolet Express 3500?A:The first step for repairing or servicing the Camshaft Position Sensor starts with disconnecting the negative Battery Cable then removing the engine cover. During service begin by disconnecting Spark Plug Wires along with the ignition coil wire from Distributor and then disconnect the cmp sensor harness connector. First disconnect the Distributor cap screws along with the Distributor cap before proceeding to separate the rotor screws and the rotor. The alignment of the square slot on the reluctor wheel with the cmp sensor allows the removal of cmp sensor fasteners and sensor retrieval. During the replacement operation utilize fresh screws modified with a thread locking compound which can be obtained through gm p/n 10475922 for Distributor cap screws and gm p/n 10475924 for rotor screws packed in sets of ten screws each. Transport the cmp sensor through the reluctor wheel slot by aligning its square slot with the sensor then bolt the new mounting screws and tighten them to 1.6-2.8 n.m (14-25 lb in). The proper rotor alignment depends on maintaining the rotor locating tabs in position before screwing the rotor onto the reluctor wheel with new screws while tightening them to 1.5-2.4 n.m (13-22 lb in). Position the Distributor cap and secure it by using new Distributor cap screws which must be tightened between 1.8-3.0 n.m (16-26 lb in). To complete the process install the engine cover along with reconnecting the negative Battery Cable after connecting the cmp sensor harness connector and reconnecting the Spark Plug Wires and ignition coil wire.

- Q: How to replace the Camshaft Position Sensor on Chevrolet Express 3500?A:The first step to replace the Camshaft Position (CMP) Sensor is to clean its surrounding area so outside matter stays out of the engine compartment. Proceed with the engine cover removal before disconnecting the CMP sensor electrical connector. Begin by taking out the CMP sensor bolt and then remove the CMP sensor from its location. You should place the CMP sensor into its proper position and follow the Fastener Notice in Service Precautions before tightening the CMP sensor bolt to 25 N.m (18 lb ft). Replace the engine cover by reconnecting the CMP sensor electrical connector.