ChevyParts

My Garage

My Account

Cart

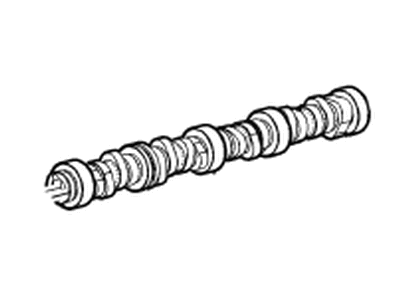

OEM Chevrolet Silverado 1500 Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Camshafts found

Chevrolet Silverado 1500 Camshaft Part Number: 12560967

$516.55 MSRP: $816.41You Save: $299.86 (37%)Ships in 1-3 Business Days

Chevrolet Silverado 1500 Camshaft Part Number: 12561721

$516.55 MSRP: $816.41You Save: $299.86 (37%)Ships in 1-3 Business Days

Chevrolet Silverado 1500 Camshaft Part Number: 12612273

$454.92 MSRP: $774.50You Save: $319.58 (42%)Ships in 1-3 Business Days

Chevrolet Silverado 1500 Camshaft Part Number: 10241691

$353.35 MSRP: $556.00You Save: $202.65 (37%)Ships in 1-3 Business Days

Chevrolet Silverado 1500 Camshaft Part Number: 12625436

$407.69 MSRP: $700.20You Save: $292.51 (42%)Ships in 1-2 Business Days

Chevrolet Silverado 1500 Camshaft Part Number: 12689035

$220.97 MSRP: $532.86You Save: $311.89 (59%)Ships in 1-2 Business Days

Chevrolet Silverado 1500 Camshaft Part Number: 12619823

$126.81 MSRP: $215.89You Save: $89.08 (42%)

Chevrolet Silverado 1500 Camshaft Part Number: 12629512

$172.70 MSRP: $236.42You Save: $63.72 (27%)Chevrolet Silverado 1500 Camshaft Part Number: 12664911

$108.53 MSRP: $186.34You Save: $77.81 (42%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Camshaft Part Number: 12698637

$100.98 MSRP: $158.13You Save: $57.15 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Camshaft Part Number: 12583227

$454.92 MSRP: $774.50You Save: $319.58 (42%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Camshaft Part Number: 55508605

$88.78 MSRP: $139.04You Save: $50.26 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Camshaft Part Number: 55508606

$92.67 MSRP: $145.12You Save: $52.45 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Camshaft Part Number: 40009063

$104.13 MSRP: $163.07You Save: $58.94 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Camshaft Part Number: 12664912

$117.39 MSRP: $201.57You Save: $84.18 (42%)Chevrolet Silverado 1500 Camshaft Part Number: 40009303

$100.27 MSRP: $157.06You Save: $56.79 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Camshaft Part Number: 12703450

$416.32 MSRP: $654.90You Save: $238.58 (37%)Ships in 1-3 Business DaysChevrolet Silverado 1500 Camshaft Part Number: 12711967

$396.90 MSRP: $681.66You Save: $284.76 (42%)Ships in 1-2 Business DaysChevrolet Silverado 1500 Camshaft Part Number: 12703806

$359.99 MSRP: $566.42You Save: $206.43 (37%)Ships in 1-3 Business Days

Chevrolet Silverado 1500 Camshaft Part Number: 12583623

$242.45 MSRP: $381.48You Save: $139.03 (37%)

| Page 1 of 2 |Next >

1-20 of 22 Results

Chevrolet Silverado 1500 Camshaft

Want to cut long-term maintenance and repair costs? Choose OEM Camshaft. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Silverado 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Silverado 1500 Camshaft includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Silverado 1500 Camshaft Parts Questions & Experts Answers

- Q: How to replace the camshaft in LH6, LMG, LY2, and LY5 engines on Chevrolet Silverado 1500?A:Begin the Camshaft replacement on lh6 lmg ly2 and ly5 engines by taking away the radiator support and valve lifters together with engine front cover and Starter motor. The j 42386-a (Flywheel Holding Tool) should have its teeth matching the engine Flywheel teeth before installation using one m10-1.5 x 120 mm and one m10-1.5 x 45 mm bolt that you must tighten to 50 n.m (37 lb ft). Rotating the crankshaft sprocket will reveal the alignment marks of the Camshaft sprocket next to the crankshaft sprocket alignment marks while avoiding any crankshaft motion following Timing Chain removal to prevent damage. Disassemble the components by first removing bolt 206 and parts 205 and 208. Finish removing parts 204 and 203 while taking care to safeguard the Camshaft bearings. Place the Camshaft sprocket bolt at the front hole of the Camshaft to act as a handle when removing the Camshaft from the engine block before removing the bolt. After cleanup of the gasket surface on the engine block install the Camshaft through the bolt as a handle while applying clean engine oil to both Camshaft journals and bearings. Screw in the Camshaft retainer (203) and bolts (204), first tighten hex head bolts created in design one to 25 n.m (18 lb ft) and second design torx(R) head bolts to 15 n.m (11 lb ft). Beginning with en 46330 (Timing Belt Tensioner Retaining Pin) installation the synchronization of Camshaft sprocket timing requires it to face 6 o'clock before Timing Chain (208) and bolt (206) assembly. Check that the Camshaft sprocket markings face 6 o'clock position since the crankshaft sprocket should display its mark at 12 o'clock position during inspection. Proceed by removing tool en 46330 and then tighten the Camshaft sprocket bolt to 90 n.m (66 lb ft) followed by 40 degrees using j 45059 (Angle Meter). Then finish the repair by eliminating both the j 42386-a and bolts before replacing the Starter motor as well as the engine front cover together with valve lifters and radiator support.