ChevyParts

My Garage

My Account

Cart

OEM GMC Sierra 1500 Starter

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Starters found

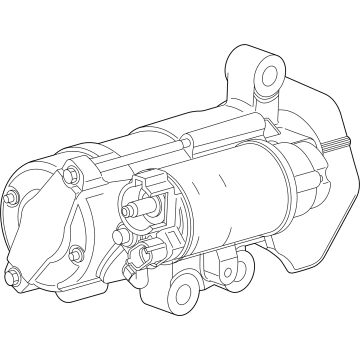

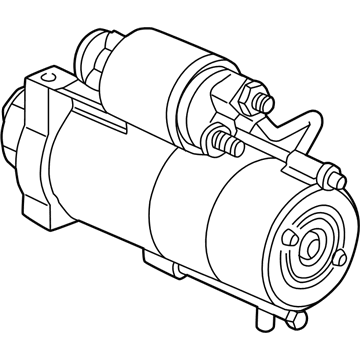

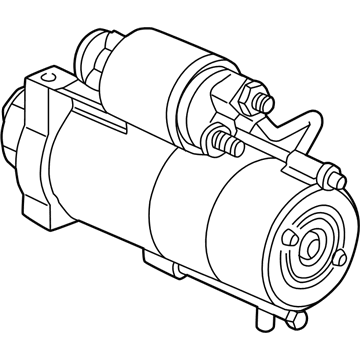

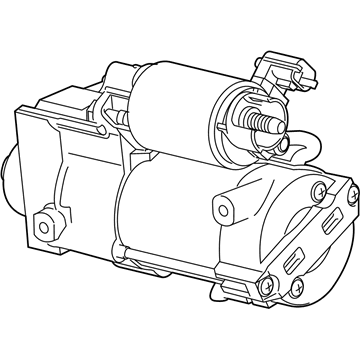

GMC Sierra 1500 Starter Part Number: 89017844

$300.03 MSRP: $659.63You Save: $359.60 (55%)Ships in 1-2 Business Days

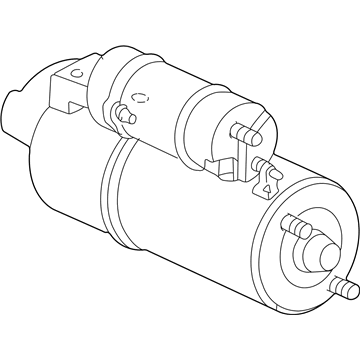

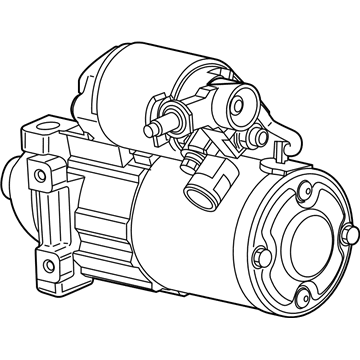

GMC Sierra 1500 Starter Part Number: 89018123

$272.12 MSRP: $538.24You Save: $266.12 (50%)Ships in 1-2 Business Days

GMC Sierra 1500 Starter Part Number: 12695760

$185.56 MSRP: $368.32You Save: $182.76 (50%)Ships in 1-2 Business Days

GMC Sierra 1500 Starter Part Number: 10465577

$330.15 MSRP: $595.83You Save: $265.68 (45%)Ships in 1-2 Business Days

GMC Sierra 1500 Starter Part Number: 89017630

$248.04 MSRP: $490.45You Save: $242.41 (50%)Ships in 1-2 Business Days

GMC Sierra 1500 Starter Part Number: 19180529

$238.30 MSRP: $471.14You Save: $232.84 (50%)Ships in 1-2 Business Days

GMC Sierra 1500 Starter Part Number: 19180528

$221.51 MSRP: $437.81You Save: $216.30 (50%)Ships in 1-2 Business Days

GMC Sierra 1500 Starter Part Number: 12652772

$99.24 MSRP: $192.17You Save: $92.93 (49%)Ships in 1-2 Business DaysGMC Sierra 1500 Starter Part Number: 89017637

$336.67 MSRP: $666.37You Save: $329.70 (50%)Ships in 1-2 Business DaysGMC Sierra 1500 Starter Part Number: 55509960

$175.15 MSRP: $317.01You Save: $141.86 (45%)GMC Sierra 1500 Starter Part Number: 89017441

$260.54 MSRP: $487.51You Save: $226.97 (47%)Ships in 1-2 Business DaysGMC Sierra 1500 Starter, Yellow Cover Part Number: 12725866

$145.39 MSRP: $288.60You Save: $143.21 (50%)Ships in 1-2 Business DaysGMC Sierra 1500 Starter Part Number: 12694627

$89.06 MSRP: $176.79You Save: $87.73 (50%)Ships in 1-3 Business DaysGMC Sierra 1500 Starter Part Number: 10465579

$289.87 MSRP: $573.50You Save: $283.63 (50%)Ships in 1-2 Business DaysGMC Sierra 1500 Starter, Red Cover Part Number: 12730103

$145.39 MSRP: $288.60You Save: $143.21 (50%)GMC Sierra 1500 Starter Part Number: 10465561

$296.11 MSRP: $585.87You Save: $289.76 (50%)Ships in 1-2 Business DaysGMC Sierra 1500 Starter Part Number: 10465385

$339.36 MSRP: $670.35You Save: $330.99 (50%)Ships in 1-2 Business DaysGMC Sierra 1500 Starter Part Number: 19180530

$171.89 MSRP: $338.64You Save: $166.75 (50%)Ships in 1-2 Business DaysGMC Sierra 1500 Starter Part Number: 12689541

$191.04 MSRP: $368.13You Save: $177.09 (49%)Ships in 1-2 Business DaysGMC Sierra 1500 Starter Part Number: 12724245

$114.04 MSRP: $226.36You Save: $112.32 (50%)

| Page 1 of 2 |Next >

1-20 of 23 Results

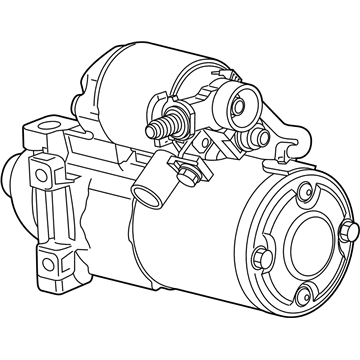

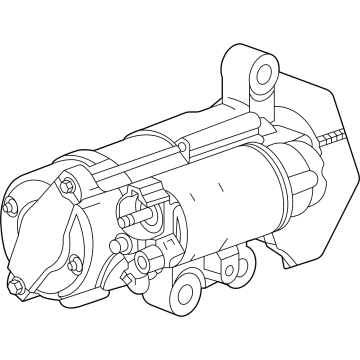

GMC Sierra 1500 Starter

Want to cut long-term maintenance and repair costs? Choose OEM Starter. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Sierra 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Sierra 1500 Starter includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Sierra 1500 Starter Parts Questions & Experts Answers

- Q: How to replace the starter motor on 4.8L, 5.3L, 6.0L, and 6.2L engines on GMC Sierra 1500?A:A replacement of the Starter motor requires users to begin by disconnecting the negative Battery Cable for 4.8l, 5.3l, 6.0l, and 6.2l engines. Support the vehicle raised position while 2500 series vehicles need you to remove their front 2 oil pan skid plate bolts together with loosening of the rear 2 bolts before skid plate extraction. Begin by removing the transmission cover bolt as well as the Starter bolts before disconnecting the engine wiring harness electrical connector from the oil level sensor. Maintain awareness of not hanging the Starter using cables or wires during this process. Set the Starter forward past the transmission then implement a proper support method. Drop the vehicle halfway to access the right front wheel and tire followed by removing the right front wheelhouse liner. Start by removing the lead nut and terminal of the Starter's engine wiring harness before removing the frame-mounted Starter solenoid clip bolt and nut to free the Starter solenoid cable . Start by extracting the Starter through the wheel well opening; when installing a new Starter, separate and take off the Starter heat shield. To install the new Starter observe the following process: start by adding the heat shield to the Starter, then attach the transmission cover onto the Starter base. Pass the Starter through the wheel well opening before connecting the Starter solenoid cable to the Starter. South to 9 nm (80 lb in) tightness is required for the solenoid cable nut. Position the Starter solenoid cable clip to the frame then bolt it tightly at 10 nm (89 lb in). Fasten the Starter's engine wiring harness lead terminal with a lead nut tightened to 3.4 nm (30 lb in). Each Starter bolt requires tightening to achieve 50 nm (37 lb ft). Install the right front wheel and tire after placing back the wheelhouse liner. Allow the vehicle to rest on stands while you join the engine harness electrical connector to the oil level sensor before installing and firmly tightening the transmission cover bolt to 9 nm (80 lb in). Owners should install the oil pan skid plate to 2500 series vehicles by tightening each bolt to 28 nm (21 lb ft); the two front bolts and two rear bolts. To complete the repair work lower the vehicle before reconnecting the negative Battery Cable.