ChevyParts

My Garage

My Account

Cart

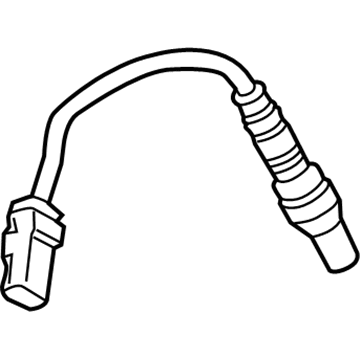

OEM Buick Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

76 Oxygen Sensors found

Buick Oxygen Sensor Part Number: 12597990

$52.78 MSRP: $107.22You Save: $54.44 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Heated Oxygen (Position 1); Front Oxygen Sensor; Sensor, Computer Control Sensors

Buick Oxygen Sensor Part Number: 12569429

$54.71 MSRP: $111.12You Save: $56.41 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Heated Oxygen (Position 1); Front Oxygen Sensor; Sensor, Computer Control Sensors

Buick Oxygen Sensor Part Number: 19178958

$65.65 MSRP: $133.34You Save: $67.69 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Computer Control Sensors; Front Oxygen Sensor; Manifold

- Replaces: 25178022, 25312203, 25312211, 25164488

Buick Oxygen Sensor Part Number: 12580466

$68.95 MSRP: $140.05You Save: $71.10 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Heated Oxygen (Position 1); Front Oxygen Sensor; Sensor, Computer Control Sensors

Buick Oxygen Sensor Part Number: 55570074

$38.15 MSRP: $77.48You Save: $39.33 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Heated Oxygen (Position 2); Lower Oxygen Sensor; Sensor, Computer Control Sensors

Buick Oxygen Sensor Part Number: 12612430

$75.26 MSRP: $139.54You Save: $64.28 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Computer Control Sensors; Rear Oxygen Sensor; Front Oxygen Sensor; Lower Oxygen Sensor

Buick Oxygen Sensor Part Number: 12594452

$54.19 MSRP: $110.06You Save: $55.87 (51%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor, Computer Control Sensors; Front Oxygen Sensor

Buick Oxygen Sensor Part Number: 19178747

$83.90 MSRP: $151.86You Save: $67.96 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Computer Control Sensors

- Replaced by: 19355307

Buick Oxygen Sensor Part Number: 12573721

$63.75 MSRP: $129.48You Save: $65.73 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Computer Control Sensors; Front Oxygen Sensor

Buick Rear Oxygen Sensor Part Number: 12604538

$100.18 MSRP: $186.94You Save: $86.76 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Heated Oxygen (Position 2); Sensor, Computer Control Sensors

Buick Oxygen Sensor Part Number: 12640115

$93.88 MSRP: $190.68You Save: $96.80 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Computer Control Sensors; Rear Oxygen Sensor

Buick Oxygen Sensor Part Number: 12573167

$54.84 MSRP: $102.98You Save: $48.14 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Heated Oxygen (Position 2); Front Oxygen Sensor; Sensor, Computer Control Sensors

Buick Oxygen Sensor Part Number: 19209805

$85.68 MSRP: $174.02You Save: $88.34 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Computer Control Sensors; Rear Oxygen Sensor

- Replaces: 12581346, 12590750, 19256730, 19210712

Buick Oxygen Sensor Part Number: 12584050

$49.06 MSRP: $88.81You Save: $39.75 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Heated Oxygen (Position 2); Rear Oxygen Sensor; Front Oxygen Sensor; Sensor, Computer Control Sensors

- Replaces: 12603139

Buick Oxygen Sensor Part Number: 19178949

$46.48 MSRP: $145.04You Save: $98.56 (68%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Computer Control Sensors

- Replaced by: 19355317

- Replaces: 25163185, 25162980, 25312195, 25312204, 25164727

Buick Oxygen Sensor Part Number: 5613719

$52.82 MSRP: $164.76You Save: $111.94 (68%)Ships in 1 Business DayProduct Specifications- Other Name: Sensor Assembly, Oxygen; Sensor

- Replaced by: 19211435

Buick Oxygen Sensor Part Number: 12656543

$62.58 MSRP: $176.24You Save: $113.66 (65%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Computer Control Sensors; Rear Oxygen Sensor; Lower Oxygen Sensor

- Replaces: 12646200, 12639693

Buick Oxygen Sensor Part Number: 12675980

$35.70 MSRP: $100.52You Save: $64.82 (65%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Heated Oxygen (Pre-Catalyst Bank 1 Se; Front Oxygen Sensor; Upper Oxygen Sensor; Sensor, Computer Control Sensors

Buick Oxygen Sensor Part Number: 12567127

$36.64 MSRP: $114.28You Save: $77.64 (68%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Computer Control Sensors; Front Oxygen Sensor

Buick Oxygen Sensor Part Number: 25176708

$55.59 MSRP: $112.89You Save: $57.30 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly, Oxygen; Sensor, Computer Control Sensors

- Replaces: 10096129

| Page 1 of 4 |Next >

1-20 of 76 Results

Buick Oxygen Sensor

Want to cut long-term maintenance and repair costs? Choose OEM Oxygen Sensor. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Buick parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Buick Oxygen Sensor includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Buick Oxygen Sensor Parts Questions & Experts Answers

- Q: How to replace the heated oxygen sensor (HO2S) at Position 1 on Buick LaCrosse?A:The replacement process for heated Oxygen Sensor (HO2S) at position 1 begins with disconnecting the Oxygen Sensor electrical connector then removing the ho2s while being mindful not to damage Exhaust Manifold/pipe threads due to avoid applying force beyond necessity. Maintain engine temperature above 48°c (120°F) because it makes removing the items easier. According to procedure, threads of new service sensors already have anti-seize compounds applied but used sensors must receive the application of anti-seize compound p/n 5613695 or any equivalent product. Fasten the ho2s with 1 to 42 n.m torque (31 lb ft) then connect the Oxygen Sensor electrical connector. The procedure demands careful handling of ho2s and o2s while maintaining their electrical connector and louvered end free from dirt and contamination. Also avoid all cleaning solvents as well as dropping sensors.

- Q: How to replace the Heated Oxygen Sensor - Bank 1 Sensor 2 on Buick Enclave?A:First to replace the heated Oxygen Sensor-bank 1 sensor 2 one should raise and support the vehicle. Take out the connector position assurance (CPA) retainer and disconnect the heated Oxygen Sensor (HO2S) electrical connector from the engine wiring harness electrical connector. Next, take the ho2s out of the Exhaust Pipe. When installing if it is a reinstallation of the old sensor, coat the threads with anti-seize compound gm p/n 12377953 or equivalent since a special anti-seize compound consisting of liquid graphite and glass beads are used in the ho2s threads to make future removal easy. Mount the ho2s to the Exhaust Pipe and fasten it at 42 nm (31 lb ft). Next, attach the ho2s electromotive connector 2 to the engine wire harness electromotive connector 1, followed by installation of the cpa retainer 1 before lowering the vehicle.

- Q: How to replace the Heated Oxygen Sensor (HO2S) on Buick Regal?A:For ho2s replacement work you need these tools: Oxygen Sensor wrench (J 39194). Oxygen Sensor wrench (J 39194). Handle both ho2s and Oxygen Sensor components with care while protecting the in-line electrical connector and louvered end from grease or contaminant exposure. Do not use any cleaning solvents during this process. Sensor removal must wait until the engine temperature reaches above 48°c (120°F) so the sensor becomes easy to extract. First disconnect the ho2s electrical connector and remove its retaining clip after dismantling the fuel injector sight shield. Move the ho2s electrical connector off its bracket mounting position. Use the Oxygen Sensor wrench j 39194 for safe removal of the right Exhaust Manifold ho2s. A newly reused sensor requires application of anti-seize compound p/n 12377953 or alternative which should be applied to sensor threads when necessary. Fasten the ho2s onto the right Exhaust Manifold with the Oxygen Sensor wrench (J 39194) to achieve a torque of 41 n.m (30 lb ft). Reinstall the fuel injector sight shield following the bracket retainer installation alongside ho2s electrical connector reattaching and wiring harness electrical connector reconnecting to the ho2s.