ChevyParts

My Garage

My Account

Cart

OEM Cadillac TPMS Sensor

Tire Pressure Monitoring System Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

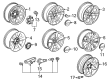

40 TPMS Sensors found

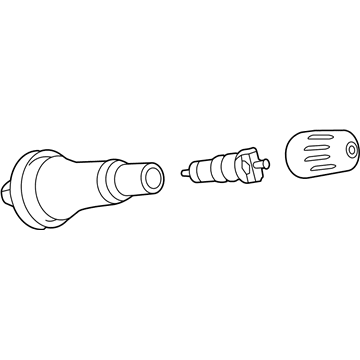

Cadillac TPMS Sensor Valve Part Number: 13581557

$4.86 MSRP: $9.12You Save: $4.26 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Nut, Tire Pressure; TPMS Sensor Service Kit; TPMS Sensor Nut; Valve Assembly Nut; Nut, Wheel & Spare Tire; Nut, Wheel

Cadillac Wheel Nut Part Number: 15234846

$7.26 MSRP: $13.64You Save: $6.38 (47%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Nut, Tire Pressure; TPMS Sensor Service Kit; Valve Stem Nut; TPMS Sensor Valve; TPMS Sensor Nut; Pressure Sensor Nut; Tire Sensor Nut; Transmitter Nut; Nut, Wheel

- Replaces: 10268439, 15825474, 15125473, 25708165

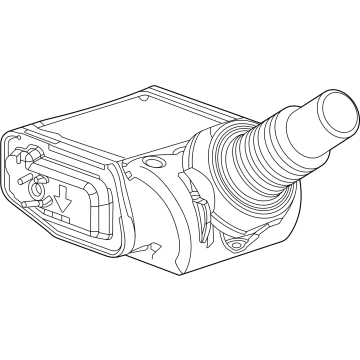

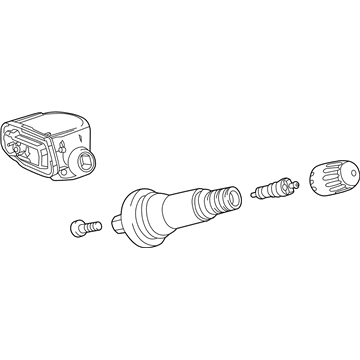

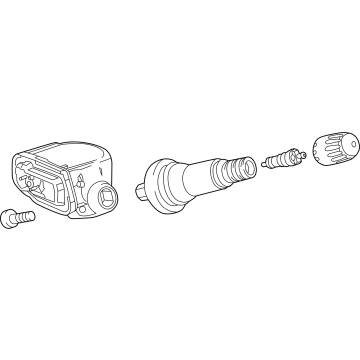

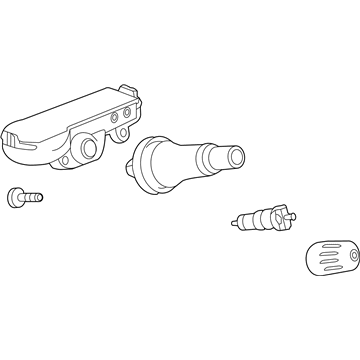

Cadillac TPMS Sensor Part Number: 25740352

$75.18 MSRP: $136.08You Save: $60.90 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor, Tire Pressure Indicator; Tire Pressure Monitoring System (TPMS) Sensor; Tire Pressure Sensor; Sensor, Tire Pressure

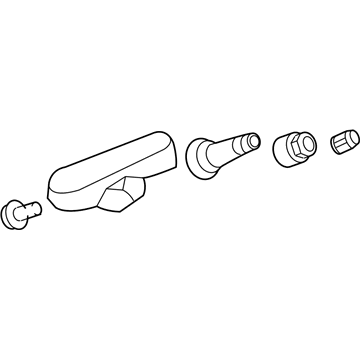

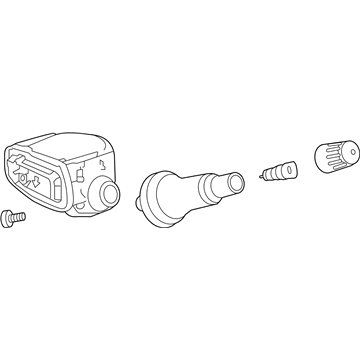

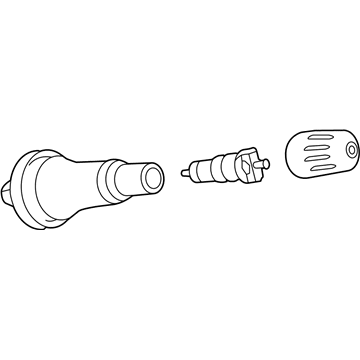

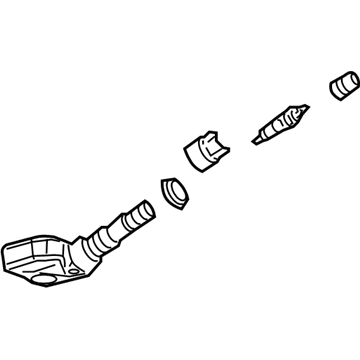

Cadillac Tire Pressure Sensor, Black Part Number: 13598909

$11.19 MSRP: $21.02You Save: $9.83 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve Kit, Tire Valve And Cover Lock; TPMS Sensor Service Kit; TPMS Sensor; Valve Stem; Repair Kit; Tire Sensor Valve; TPMS Sensor Valve Assembly; Tire Valve Kit; Vehicle Security & Safety.

- Replaces: 15263240, 19368646

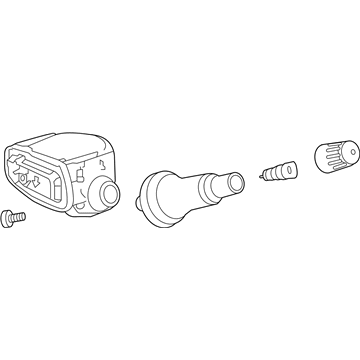

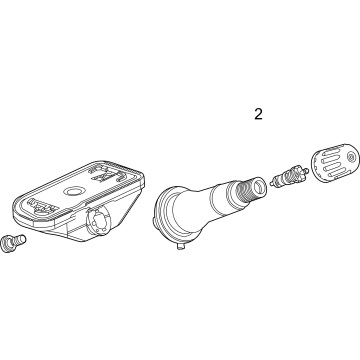

Cadillac TPMS Sensor Part Number: 13545364

$98.80 MSRP: $176.42You Save: $77.62 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Sensor Assembly-Tire Pressure Indicator; Sensor, Vehicle Security & Safety; Sensor, Tire Pressure

Cadillac TPMS Sensor Part Number: 13538761

$38.51 MSRP: $68.76You Save: $30.25 (44%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Tire Pressure Indicator; Tire Pressure Sensor; Sensor; Sensor, Vehicle Security & Safety; Sensor, Tire Pressure

- Replaced by: 13556202

Cadillac TPMS Sensor Part Number: 13556202

$38.51 MSRP: $68.76You Save: $30.25 (44%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Tire Pressure Indicator; Sensor, Vehicle Security & Safety; Sensor, Tire Pressure

- Replaces: 13530661, 13593960, 13538761

Cadillac TPMS Sensor Part Number: 13540606

$27.10 MSRP: $50.90You Save: $23.80 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Tire Pressure Indicator; Tire Pressure Sensor; Sensor, Vehicle Security & Safety; Sensor, Tire Pressure

- Replaces: 13512347

Cadillac TPMS Sensor Part Number: 13538759

$34.78 MSRP: $62.10You Save: $27.32 (44%)Product Specifications- Other Name: Sensor Assembly-Tire Pressure Indicator; Sensor, Tire Pressure

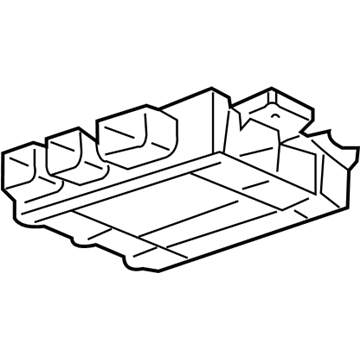

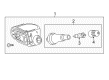

Cadillac Receiver Part Number: 20803737

$91.17 MSRP: $162.80You Save: $71.63 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Receiver Assembly-Remote Control Door Lock; Receiver, Door Lock Remote Control Inside; Receiver, Door Electric And Vacuum Locks; Module, Tire Pressure

- Replaces: 25856316, 25938218

Cadillac TPMS Sensor Part Number: 22959744

$30.59 MSRP: $57.44You Save: $26.85 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Tire Pressure Indicator; Tire Pressure Monitoring System (TPMS) Sensor; TPMS Capteur; Sensor

- Replaces: 20983526, 22886615

Cadillac TPMS Sensor Part Number: 13540607

$27.15 MSRP: $50.98You Save: $23.83 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Assembly-Tire Pressure Indicator; Tire Pressure Sensor; Sensor, Vehicle Security & Safety; Sensor, Tire Pressure

- Replaces: 13512346

Cadillac TPMS Sensor Part Number: 13538760

$26.86 MSRP: $50.44You Save: $23.58 (47%)Product Specifications- Other Name: Sensor Assembly-Tire Pressure Indicator; Tire Pressure Sensor; Sensor

- Replaced by: 13554170

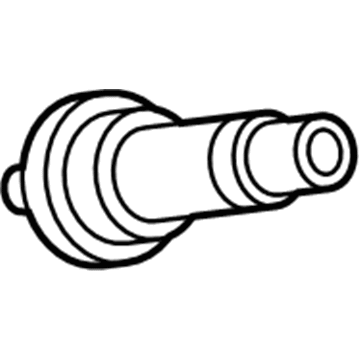

Cadillac TPMS Sensor Valve Assembly Part Number: 22959739

$3.16 MSRP: $5.90You Save: $2.74 (47%)Product Specifications- Other Name: Valve Kit, Tire Valve And Cover Lock; TPMS Sensor Service Kit

Cadillac TPMS Sensor Part Number: 13542523

$26.01 MSRP: $48.84You Save: $22.83 (47%)Product Specifications- Other Name: Sensor Assembly-Tire Pressure Indicator; Tire Pressure Sensor; Stem, Tire Valve And Cover Lock; Sensor, Tire Pressure

- Replaces: 13533166

Cadillac TPMS Sensor Part Number: 13540602

$29.85 MSRP: $56.06You Save: $26.21 (47%)Product Specifications- Other Name: Sensor Assembly-Tire Pressure Indicator; Tire Pressure Sensor; Sensor; Sensor, Vehicle Security & Safety; Sensor, Tire Pressure

- Replaces: 13581561, 20922901, 25880395, 13589256, 13598773, 22853740, 13589601

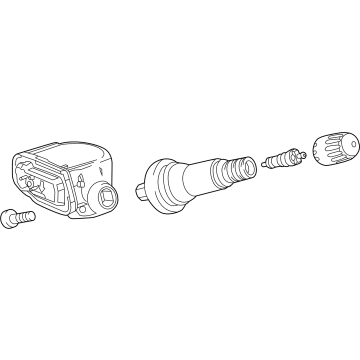

Cadillac Tire Pressure Sensor Part Number: 84413350

$33.60 MSRP: $40.00You Save: $6.40 (16%)Product Specifications- Other Name: Tire Pressure Monitor (Xl8-433Mhz); TPMS Sensor; Sensor Package, Vehicle Security & Safety

- Replaces: 19119269, 19332515, 19119333, 20951302, 19242930

Cadillac Tire Pressure Sensor Part Number: 85519338

$33.60 MSRP: $40.00You Save: $6.40 (16%)Product Specifications- Other Name: Tire Pressure Monitor (Xl7-314.9 Mhz); Valve Stem; Sensor Package, Vehicle Security & Safety; Sensor Package, Tire Pressure

- Replaces: 19333061, 84576926, 84413354

Cadillac Control Module Part Number: 15866242

Product Specifications- Other Name: Module Assembly-Low Tire Pressure Indicator; Module, Tire Pressure

Cadillac Tire Pressure Sensor Part Number: 25789964

Product Specifications- Other Name: Sensor, Tire Pressure Indicator; TPMS Sensor; Pressure Sensor; Sensor, Tire Pressure

- Replaces: 15254102, 25809220

| Page 1 of 2 |Next >

1-20 of 40 Results

Cadillac TPMS Sensor

Want to cut long-term maintenance and repair costs? Choose OEM TPMS Sensor. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac TPMS Sensor includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Cadillac TPMS Sensor Parts Questions & Experts Answers

- Q: How to replace the TPMS Sensor on Cadillac CTS?A:To replace the Tire Pressure Sensor first, lift the vehicle with a suitable support and the removal of the tire/wheel assembly. Before taking off the tire, locate the cap and valve of the sensor on a clean surface which is such that the cap con be aluminum while the valve topped with a nickel plating to avoid corrosion. When breaking the tire bead away from the wheel mate the bead breaking fixture at a 90-degree angle to the valve stem and tension the tire iron or pry bar slightly clockwise of the sensor body while lifting the tire bead up and over the mounting/dismounting head. Apply the tire machine to rotate the tire/wheel assembly clockwise while moving the tire bead to the outer part of the wheel rim and vice versa in the case of the inner bead. After removing the tire ensure that all the left over tire sealant from the tire and wheel surfaces is scrapped out, then unfasten the tire pressure sensor nut and the sensor. For installation, it is imperative that the grommet sealing area is free from any form of dirt, as the same is to be inserted into the wheel hole at an angle where the air passage is strategically opposite to the wheel, with the sensor body strategically placed parallel to the wheel interior, to be fastened by the sensor nut to the torque of 7 N.m (62 lb in). Before tire installation, place the mounting/dismounting head 180 degrees from valve stem and 45 degrees counterclockwise of bead transition area, then turn the tire/wheel assembly clockwise to move the tire bead inside of wheel rim and do the same for the outer bead. Mount the tire onto the wheel and record that a service replacement tire pressure sensor will ship in the OFF mode and must be spun over 32 km/h (20 mph) for at least 10 seconds to activate. Lastly, mount the tire/wheel assembly onto the car, lower the car, and familiarize yourself with the tire pressure sensors.

- Q: How to replace the TPMS Sensor on Cadillac SRX?A:A suitable vehicle support enables replacing the Tire Pressure Sensor through first removing tire/wheel assemblies from the vehicle. You should position the sensor's cap and valve on a clean surface before tire dismounting but only use aluminum caps alongside nickel-plated valves to stop corrosion. To pry the tire bead away from the wheel you should direct the bead breaking fixture at a 90 angle relative to the valve stem followed by gently pushing a tire iron or pry bar counterclockwise of the sensor body to lift the tire bead past the mounting and dismounting head. The tire machine helps the operator move tire/wheel assemblies in a clockwise direction to move tire beads outside the wheel rim before taking off the tire. Users must thoroughly remove all tire sealant residue from both the wheel surface and tire before moving on to remove the sensor components. Wipe away all dirt and debris from the grommet area before directing the sensor's air passage away from the wheel when you install it through the wheel hole. When installing the sensor nut position the sensor body at a right angle to the wheel's interior surface before tightening it to 7 Nm (62 inch lbs.). When replacing the tire position your mounting/dismounting head at 180 degrees to the valve stem and set the bead transition area 45 degrees left of the valve stem. You should begin by rotating the tire/wheel combination clockwise during bead transfer to the wheel rim interior before repeating this action on the outer bead before wheel installation. Service replacement tire pressure sensors enter the market in OFF mode but require the motorized rotation of tire/wheel assemblies to at least 20 mph (32 km/h) speeds for ten seconds to set their internal roll switch to the closed position. Learning of tire pressure sensors completes the installation process after the tire/wheel assembly is fitted onto the vehicle and then the vehicle is lowered.

- Q: How to replace the TPMS Sensor on Cadillac XLR?A:When replacing the Tire Pressure Indicator Sensor start by lifting your vehicle onto proper support equipment. Move the tire/wheel assembly away from the vehicle. Then place the valve cap and nickel-plated valve onto a clean dry surface where you will set them before tire extraction. Make sure the aluminum cap is present. The tire machine fixture should be placed at a 90-degree angle from the valve stem and the removal process demands a precise tolerance among the tire machine fixture or irons, tire bead, and sensor. Remove all tire sealant residue that remains inside the tire and wheel surfaces. Start by taking off the tire pressure sensor nut followed by the tire pressure sensor itself. To install the sensor first clean all debris from around the wheel's sensor grommet sealing section then place the sensor in the valve stem opening with the airflow channel facing opposite the wheel surface and last tight the sensor nut to 7 N.m (62 lb in) while positioning the sensor body straight against the wheel wall. Leave a gap between the tire machine and tire bead along with sensor that will fit when you reunite the tire with the wheel. Start by installing the tire onto the wheel before placing the tire/wheel combination on the vehicle and lowering the vehicle to the ground. The last step involves mastering tire pressure sensor operation.